Work winch, Stand ard installa tion instructions – Pace-Edwards Utility Rig Rack User Manual

Page 9

WORK WINCH

™

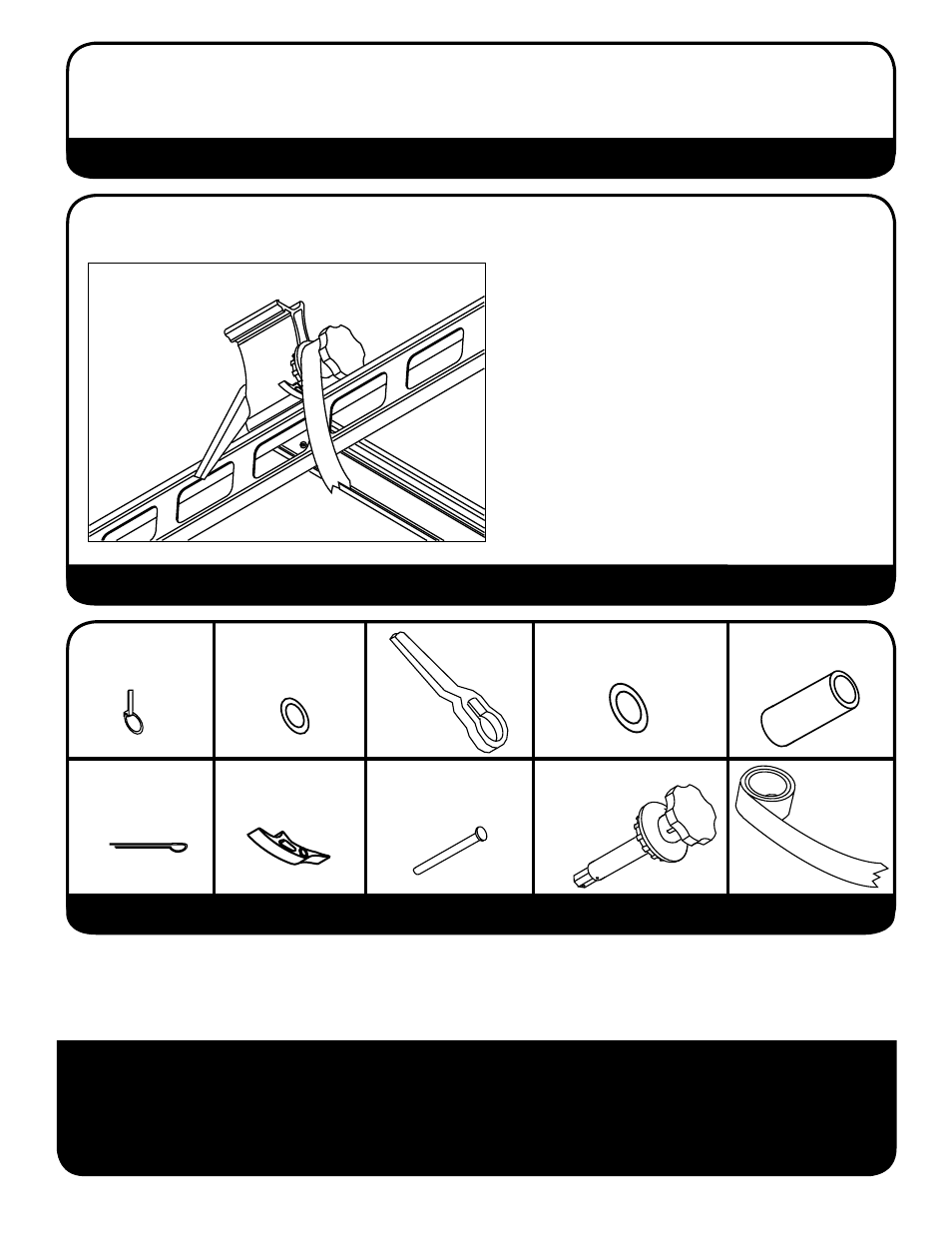

Insert 6” of the strap end into the slot in the mandrel and wind in a direction so that the top of the spool comes toward

you (If the handle has been installed, disengage it from its upper position and let it hang freely so the hex can rotate

within it). If the pawl is installed correctly, this is the only direction you will be able to turn the winch without lifting

the pawl.

Suggested park position for handle

STEP 1: INSTALL W

ORK WINCH IN GUSSET

Slide 1 of the 2 large washers onto the winch shaft.

Then install the PVC bearing, then insert the assembly

halfway into the hole in the gusset.

Orient the pawl (which is shaped like a dolphin) so that

its nose is facing away from you and slide the 2” clevis

pin through the pawl and into the small hole above the

winch shaft.

Slide the winch the rest of the way into the hole. Install

the other large washer and then the cotter pin. Hold

onto the winch take-up wheel and spread the cotter pin

with a pair of pliers.

The handle can be installed or left in a tool box or other

accessible place. If it is to be installed, place the handle

over the hex, install the smaller washer and then insert

the lynch pin and lock it.

If handle is to be kept on winch shaft, engage as shown to prevent swinging and wear

The Work Winch is installed on Contractor Rig rack after the entire rack has been assembled and installed. 4 W

ork

Winches are included with the Contractor Rig Rack and can be installed with the winch on the right and handle on the left

or it can be installed with the winch on the left and the handle on the right (a mirror image).

STAND

ARD INSTALLA

TION INSTRUCTIONS

INTEGRATED

TIE-DOWN SYSTEM (INCLUDED WITH CONTRACTOR RIG RACK)

WORK WINCH BO

X CONTENTS:

CLEVIS PIN (x4)

SMALL W

ASHER (x4)

HANDLE (x4)

LARGE WASHER (x8)

PVC BEARING (x 4)

STRAP (x4)

COTTER PIN (x 4)

WINCH SHAFT (x 4)

LYNCH PIN (x 4)

PA

WL (x4)

STEP 2: INSTALL THE STRAP

WORK WINCH

1