Step 8: install decal o ver splice joints – Pace-Edwards Utility Rig Rack User Manual

Page 11

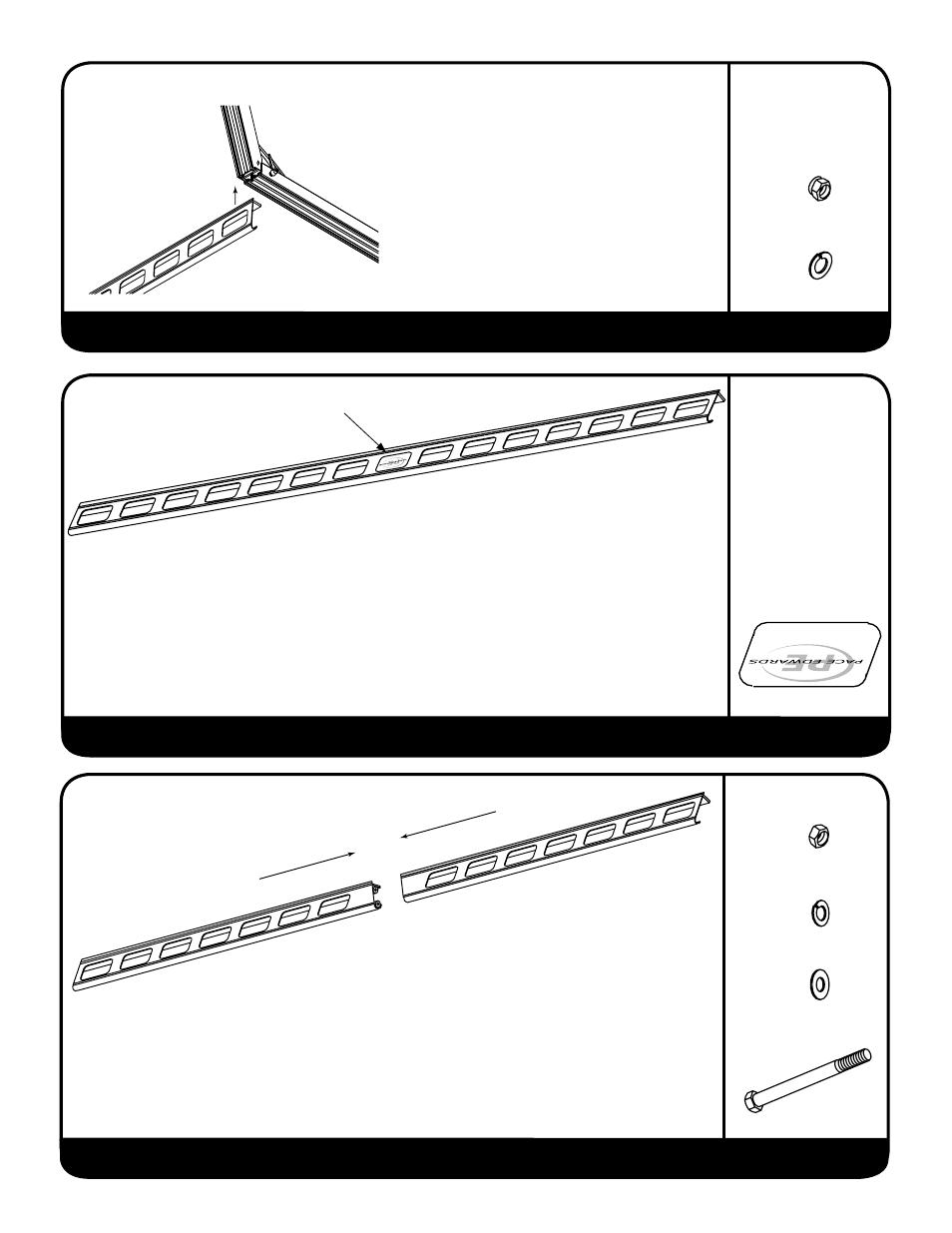

STEP 7: ASSEMBLE EXTENSION BEAM HALVES

STEP 9: INSTALL EXTENSION BEAMS ON TR

USSES

HARDWARE USED:

HARDWARE USED:

5/16” STAINLESS

NUTS (x 8)

STEP 8: INSTALL DECAL O

VER SPLICE JOINTS

You will need a smooth clean surface where you can bolt together the halves of the Extension

Beams (ie. cardboard, paper, plastic).

Locate a matching pair of Extension Beams (all holes leaning the same way) and place them

end to end so that the welded-in splice blocks touch each other and the holes in the splice

blocks align. Slide a 3/8” fl

at washer on the 4” bolt and insert the bolt through the splice blocks,

then install a fl

at washer, then lock washer

, then nut, in that order. Repeat the procedure for

the other hole, align Extension Beam halves so that the outside surfaces meet smoothly, and

then tighten nuts. Repeat the procedure for the remaining Extension Beam.

CONTRACTOR RIG RACK

6

(800)

338-3697

3/8” STAINLESS LOCK

WASHERS (x8)

3/8” STAINLESS NUT

(x4)

4-3/8” STAINLESS

BOLTS (x 4)

PA

RALLELOGRAM

DECALS (x2)

3/8” STAINLESS FLA

T

WASHERS (x4)

HARDWARE USED:

Important! There are left and right decals! Decal leans forward just like Extension Beam

holes do!

Position the decal accurately so that it repeats the punched hole pattern. Although the decal

can be installed dry, the “wet method” makes the job much easier

. Just add 10 or 12 drops

of dish washing liquid to a glass of water, pull of

f the decal backing, wet the decal and the

Extension Beam and apply the decal centered between holes over the splice joint. This

wet method allows you to slide the decal around to position it correctly. When correctly

positioned, force out excess water with fi

ngers or a sponge. The decal will ultimately adhere

with just as much “grip” as the dry method would but without the risk of misalignment,

bubbles, creases etc.

DECAL

Mount one Extension Beam on the T

russes

(notched end goes in front), aligning the end

of the beam with the rear surface of the rear

Truss.

Install lock washers and nuts and tighten

these two Extension Beam mounting bolts.

Set the other Extension Beam on the opposite

side and loosely install a lock washer and nut

on the rear T

russ only, as you will need to lift

the forward end slightly off the front truss to

assemble the crossmember.

5/16” STAINLESS LOCK

WASHERS (x 8)