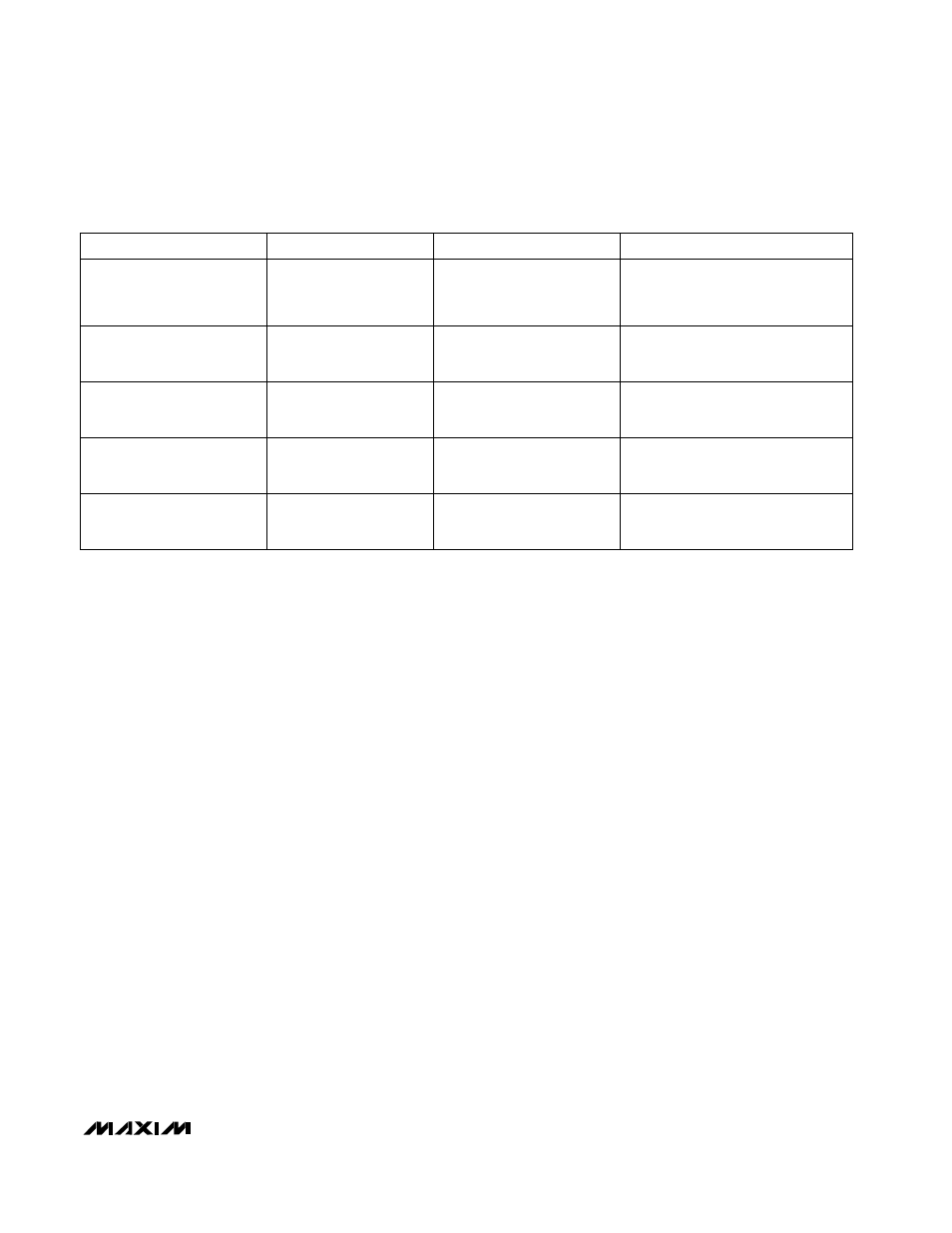

Table 6. low-voltage troubleshooting chart – Rainbow Electronics MAX1636 User Manual

Page 21

where R

DC

is the DC resistance of the coil, R

DS(ON)

is

the MOSFET on-resistance, and R

SENSE

is the current-

sense resistor value. The R

DS(ON)

term assumes identi-

cal MOSFETs for the high-side and low-side switches

because they time-share the inductor current. If the

MOSFETs are not identical, their losses can be estimat-

ed by averaging the losses according to duty factor.

PD(tran) = transition loss = V

IN

x I

LOAD

x f x 3/2 x

[(V

IN

C

RSS

/ I

GATE

) + 20ns]

where C

RSS

is the reverse transfer capacitance of the

high-side MOSFET (a data-sheet parameter), I

GATE

is

the DH gate-driver peak output current (1.5A typ), and

20ns is the rise/fall time of the DH driver (20ns typ).

P(gate) = Q

g

x f x VL

where VL is the internal logic-supply voltage (+5V), and

Q

g

is the sum of the gate-charge values for low-side

and high-side switches. For matched MOSFETs, Q

g

is

twice the data-sheet value of an individual MOSFET. If

V

OUT

is set to less than 4.5V, replace VL in this equa-

tion with V

BATT

. In this case, efficiency can be

improved by connecting VL to an efficient 5V source,

such as the system +5V supply.

P(diode) = diode conduction losses =

I

LOAD

x V

FWD

x t

D

x f

where t

D

is the diode-conduction time (120ns typ), and

V

FWD

is the forward voltage of the diode. This power is

dissipated in the MOSFET body diode if no external

Schottky diode is used.

P(cap) = input capacitor ESR loss = I

RMS2

x R

ESR

where I

RMS

is the input ripple current as calculated in

the Input Capacitor Value section.

Light-Load Efficiency Considerations

Under light loads, the PWM operates in discontinuous

mode, where the inductor current discharges to zero at

some point during the switching cycle. This makes the

inductor current’s AC component high compared to the

load current, which increases core losses and I

2

R loss-

es in the output filter capacitors. For best light-load effi-

ciency, use MOSFETs with moderate gate-charge

levels and use ferrite, MPP, or other low-loss core mate-

rial. Avoid powdered-iron cores; even Kool-Mu

(aluminum alloy) is not as good as ferrite.

PC Board Layout Considerations

Good PC board layout is required in order to achieve

specified noise, efficiency, and stable performance.

The PC board layout artist must be given explicit

instructions, preferably a pencil sketch showing the

placement of power-switching components and high-

current routing. See the PC board layout in the

MAX1636 evaluation kit manual for examples. A ground

plane is essential for optimum performance. In most

applications, the circuit will be located on a multi-layer

board, and full use of the four or more copper layers

is recommended. Use the top layer for high-current

MAX1636

Low-Voltage, Precision Step-Down

Controller for Portable CPU Power

______________________________________________________________________________________

21

CONDITION

Low V

IN

-V

OUT

differential, <1V

Maximum duty-cycle limits

exceeded.

Low V

IN

-V

OUT

differential, <1.5V

Dropout voltage is too high

(V

OUT

follows V

IN

as V

IN

decreases)

Reduce operation to 200kHz.

Reduce MOSFET on-resistance and

coil DCR.

SYMPTOM

Low V

IN

-V

OUT

differential, <0.5V

ROOT CAUSE

Normal function of internal

low-dropout circuitry.

Unstable—jitters between

different duty factors and

frequencies

Limited inductor-current

slew rate per cycle.

Increase the minimum input voltage

or ignore.

Low input voltage, <4.5V

VL output is so low that it

hits the VL UVLO threshold.

Low input voltage, <5V

Won’t start under load or

quits before battery is

completely dead

Supply VL from an external source

other than V

IN

, such as the system

+5V supply.

VL linear regulator is going

into dropout and isn’t provid-

ing good gate-drive levels.

SOLUTION

Poor efficiency

Use a small 20mA Schottky diode

for boost diode. Supply VL from an

external source.

Sag or droop in V

OUT

under

step-load change

Increase bulk output capacitance

per formula (see Low-Voltage

Operation section). Reduce inductor

value.

Table 6. Low-Voltage Troubleshooting Chart