Pmics with dynamic core for pdas and smart phones, Chip information, Pin configurations – Rainbow Electronics MAX1587A User Manual

Page 28: Pc board layout and routing, Increasing v3 (vcc_core) voltage range

MAX1586A/MAX1586B/MAX1587A

High-Efficiency, Low-I

Q

PMICs with

Dynamic Core for PDAs and Smart Phones

28

______________________________________________________________________________________

active. In addition to biasing V7, the rechargeable bat-

tery may be required to also power other supplies.

Rechargeable NiMH Backup Battery

In some systems, a NiMH battery may be desired for

backup. Usually this requires multiple cells because

the typical NiMH cell voltage is only 1.2V. By adding a

small DC-DC converter (MAX1724), the low-battery

voltage is boosted to 3V to bias BKBT (Figure 8). The

DC-DC converter’s low operating current (1.5µA typ)

allows it to remain on constantly so the 3V BKBT bias is

always present. A resistor and diode trickle charge the

NiMH cell when the main power is present.

PC Board Layout and Routing

Good PC board layout is important to achieve optimal

performance. Conductors carrying discontinuous cur-

rents and any high-current path should be made as

short and wide as possible. A separate low-noise

ground plane containing the reference and signal

grounds should connect to the power-ground plane at

only one point to minimize the effects of power-ground

currents. Typically, the ground planes are best joined

right at the IC.

Keep the voltage feedback network very close to the

IC, preferably within 0.2in (5mm) of the FB_ pin. Nodes

with high dV/dt (switching nodes) should be kept as

small as possible and should be routed away from

high-impedance nodes such as FB_. Refer to the

MAX1586 or MAX1587 evaluation kit data sheets for a

full PC board example.

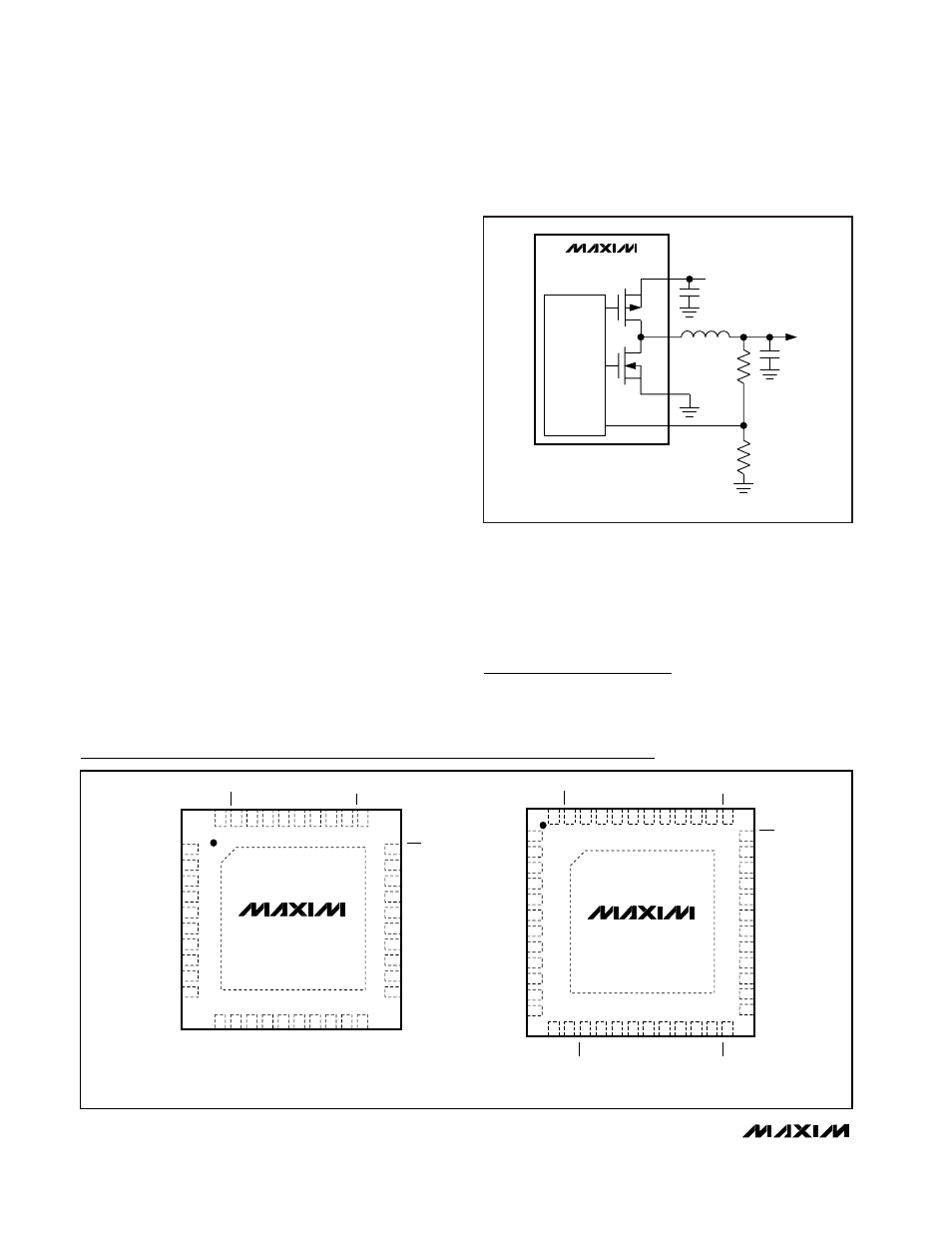

Increasing V3 (VCC_CORE) Voltage Range

The programmable V3 output voltage range can be

increased by adding two resistors as shown in Figure 9.

Chip Information

TRANSISTOR COUNT: 13,958

PROCESS: BiCMOS

TOP VIEW

RSO

SRAD

LX3

PG3

V4

ON45

ON2

V5

IN45

PV3

V7

V1

SLPIN

V2

FB2

CC2

POK

SCL

BKBT

FB1

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

25

24

23

22

21

PG2

IN

RAMP

REF

BYP

LX2

PV2

PWM3

SDA

SLP

PV1

LX1

PG1

ON1

ON3

FB3

CC3

MR

CC1

THIN QFN

6mm

×

6mm

MAX1587AETL

GND

RSO

SRAD

LX3

PG3

V4

ON4

ON2

ON5

ON3

V5

IN45

PV3

V7

V1

SLPIN

V2

FB2

CC2

CC1

POK

SCL

BKBT

FB1

LB1

PG2

IN

RAMP

REF

BYP

LX2

PV2

LBO

PWM3

SDA

SLP

PV1

LX1

PG1

IN6

V6

ON6

ON1

FB3

CC3

MR

DBI

THIN QFN

7mm

×

7mm

MAX1586AETM

MAX1586BETM

GND

DBO

1

2

3

4

5

6

7

8

9

10

11

12

36

35

34

33

32

31

30

29

28

27

26

25

48

47

46

45

44

43

42

41

40

39

38

37

13

14

15

16

17

18

19

20

21

22

23

24

Pin Configurations

PV3

STEP-DOWN

PWM

REG3

R24 VALUES:

R24 = 3.32kΩ, V3: 0.73V TO 1.55V, 26mV/STEP

R24 = 5.11kΩ, V3: 0.75V TO 1.60V, 27mV/STEP

R24 = 7.5kΩ, V3: 0.78V TO 1.65V, 28mV/STEP

LX3

PG3

FB3

V3

VCC_CORE

TO BATT

R25

100kΩ

R24

MAX1586

MAX1587

Figure 9. Adding R24 and R25 to Increase Core Voltage

Programming Range