Table 3. approximate k-factor errors – Rainbow Electronics MAX17101 User Manual

Page 19

MAX17101

Dual Quick-PWM, Step-Down Controller

with Low-Power LDO, RTC Regulator

______________________________________________________________________________________

19

Free-Running Constant-On-Time PWM

Controller with Input Feed-Forward

The Quick-PWM control architecture is a pseudo-fixed-

frequency, constant on-time, current-mode regulator

with voltage feed-forward. This architecture relies on

the output filter capacitor’s ESR to act as a current-

sense resistor, so the feedback ripple voltage provides

the PWM ramp signal. The control algorithm is simple:

the high-side switch on-time is determined solely by a

one-shot whose pulse width is inversely proportional to

input voltage and directly proportional to output volt-

age. Another one-shot sets a minimum off-time (300ns

typ). The on-time one-shot is triggered if the error com-

parator is low, the low-side switch current is below the

valley current-limit threshold, and the minimum off-time

one-shot has timed out.

On-Time One-Shot

The heart of the PWM core is the one-shot that sets the

high-side switch on-time. This fast, low-jitter, adjustable

one-shot includes circuitry that varies the on-time in

response to battery and output voltage. The high-side

switch on-time is inversely proportional to the battery

voltage as sensed by the IN input, and proportional to

the output voltage:

On-Time = K (V

OUT

/V

IN

)

where K (switching period) is set by the trilevel TON

input (see the

Pin Description

section). High-frequency

(400kHz/500kHz) operation optimizes the application

for the smallest component size, trading off efficiency

due to higher switching losses. This might be accept-

able in ultra-portable devices where the load currents

are lower and the controller is powered from a lower

voltage supply. Low-frequency (200kHz/300kHz) oper-

ation offers the best overall efficiency at the expense of

component size and board space.

For continuous conduction operation, the actual switching

frequency can be estimated by:

where V

DROP1

is the sum of the parasitic voltage drops

in the inductor discharge path, including synchronous

rectifier, inductor, and PCB resistances; V

DROP2

is the

sum of the resistances in the charging path, including

the high-side switch, inductor, and PCB resistances;

and t

ON

is the on-time calculated by the MAX17101.

f

V

V

t

V

V

SW

OUT

DROP

ON

IN

DROP

=

+

+

1

2

(

)

SWITCHING

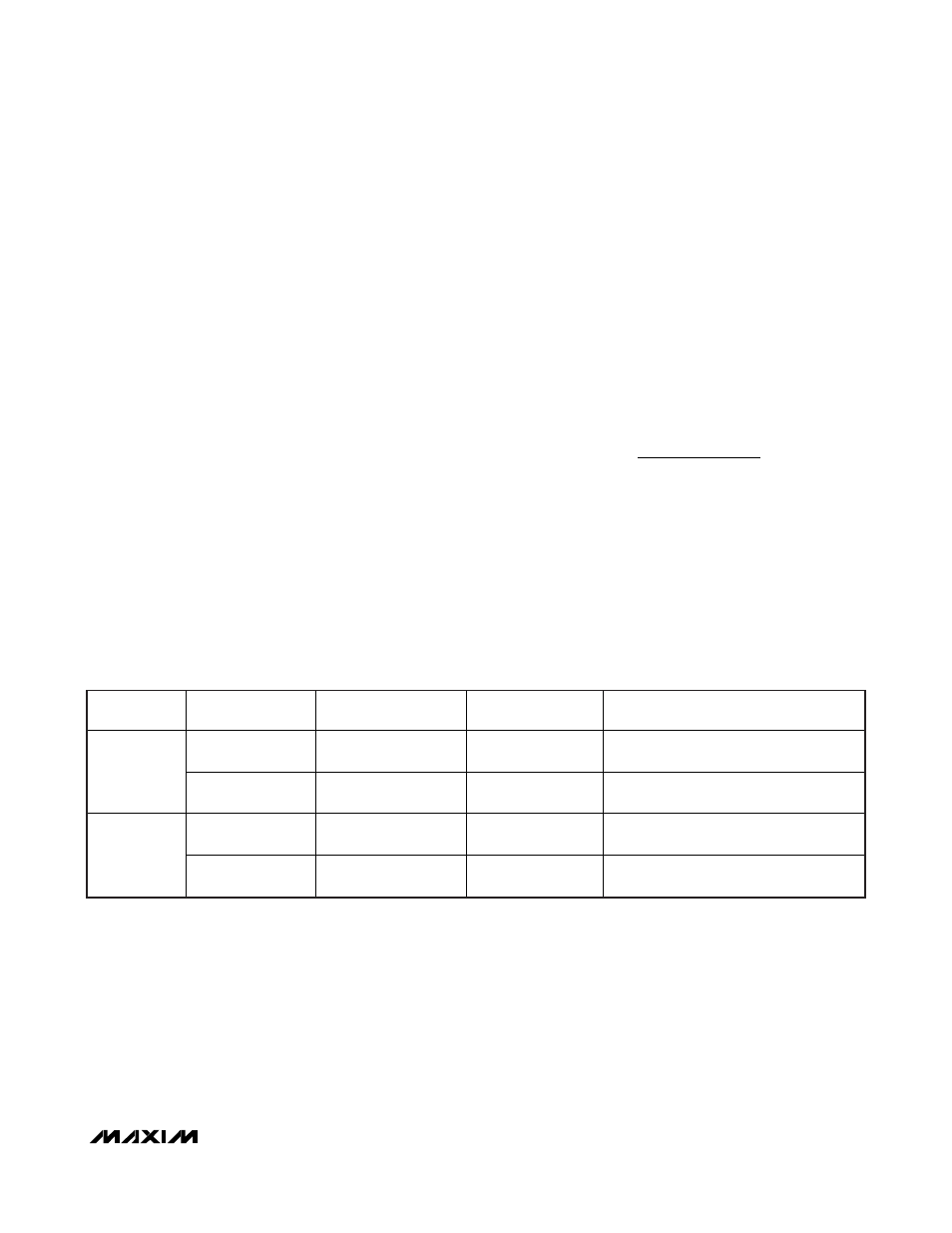

REGULATOR

TON SETTING

(kHz)

TYPICAL K-FACTOR

(μs)

K-FACTOR ERROR

(%)

COMMENTS

200

TON = V

CC

5.0

±10

Use for absolute best efficiency.

SMPS 1

400

TON = REF or GND

2.5 ±12.5

Useful in 3-cell systems for lighter loads

than the CPU core or where size is key.

300

TON = REF or V

CC

3.3 ±10

Considered mainstream by current

standards.

SMPS 2

500

TON = GND

2.0 ±12.5

Good operating point for compound buck

designs or desktop circuits.

Table 3. Approximate K-Factor Errors