Rotary axis – OMAX Rotary Axis User Manual

Page 2

ROTARY AXIS

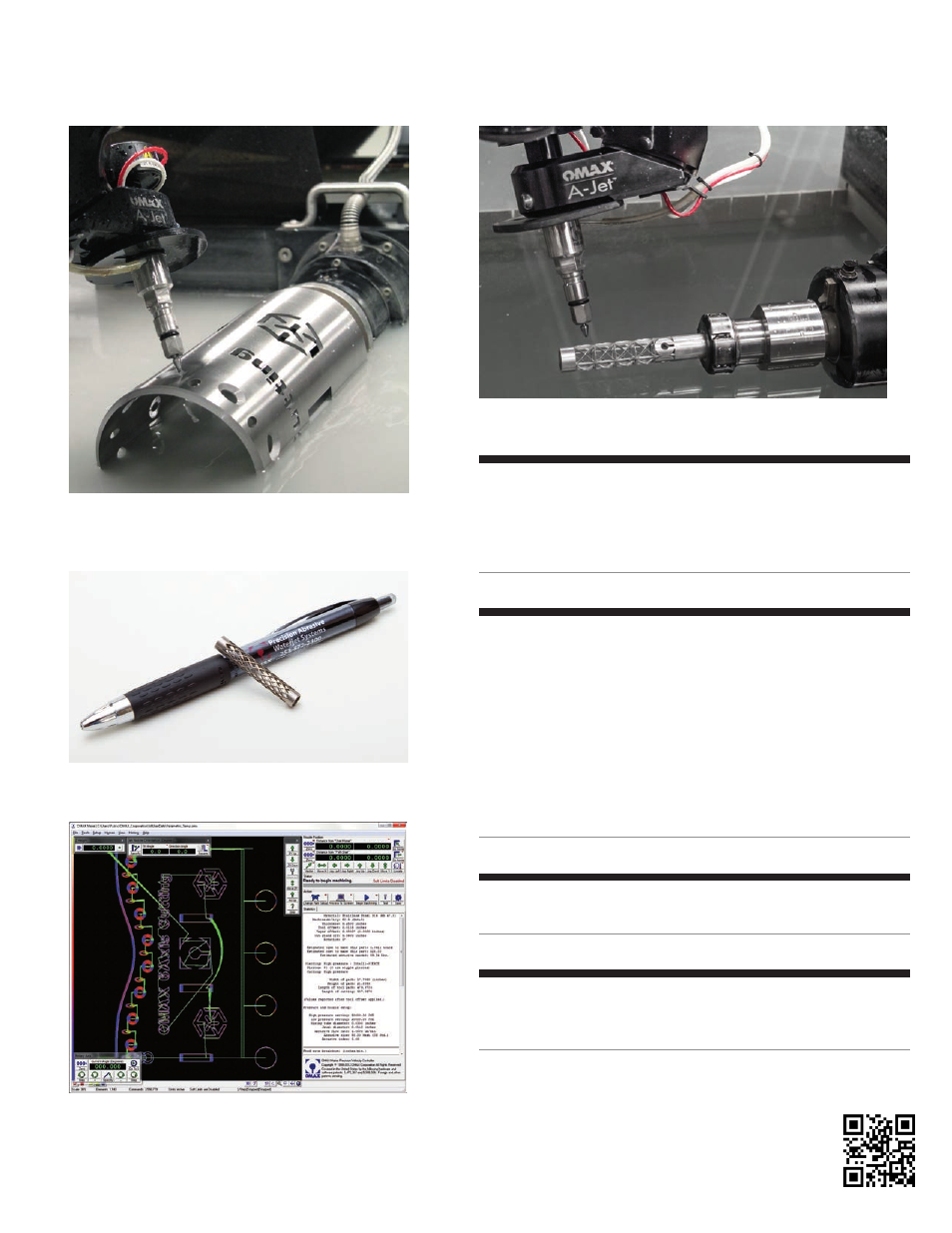

When used with the A-Jet, oblique angle and bevel-edged

holes can be cut along the circumference of pipes.

Programming for Rotary Axis cutting is simple, with advanced

tools built into the Intelli-MAX Software Suite.

ADVANCED 3D CAPABILITY

The continuous motion of the Rotary Axis coupled with advanced software

features in the latest Intelli-MAX Software Suite and the A-Jet articulated cutting

head opens up new capabilities of your OMAX JetMachining Center. Complex

beveled openings can be generated parametrically for simple creation of

challenging weld prep pipe fittings.

CAPABILITIES

•

10,000 steps per revolution standard

•

11 ft-lb (15N*m) constant torque; 28 ft-lb (39N*m) maximum torque

•

Maximum radial load at end of output shaft 391 lbf (1.74kN)

•

Maximum radial load 12” from end of the output shaft 67 lbf (0.289kN)

•

Maximum radial load 24” from end of the output shaft 36 lbf (0.164kN)

•

On larger format machines, maximum diameter 24” (cannot exceed load or

torque limit)

•

0.01 degree of repeatability: at 1” diameter = 0.0001”; at

10” diameter = 0.0008”

•

XYZ and A axes with standard motorized Z; XYZ, A, TX, and TY with Tilt-A-Jet

or A-Jet cutting head

REQUIREMENTS

•

9-axis controller back panel design for installation

•

OMAX Intelli-MAX® 18 Software Suite or later

RECOMMENDED ACCESSORIES

•

Universal Adapter Flange Blank

•

ER40 Collet Adapter with ½”, ¾”, and 1” collet sizes

•

Extension Cable Assembly to locate Rotary Control Box further away

The Rotary Axis can cut small diameter tube and pipe with

high precision.

OMAX CORPORATION

21409 72nd Avenue South

Kent, WA 98032

TEL

1-253-872-2300

/

1-800-838-0343

FAX

1-253-872-6190

WWW.OMAX.COM

Made in the USA

Specifications subject to change without notice.

600079B January 2014