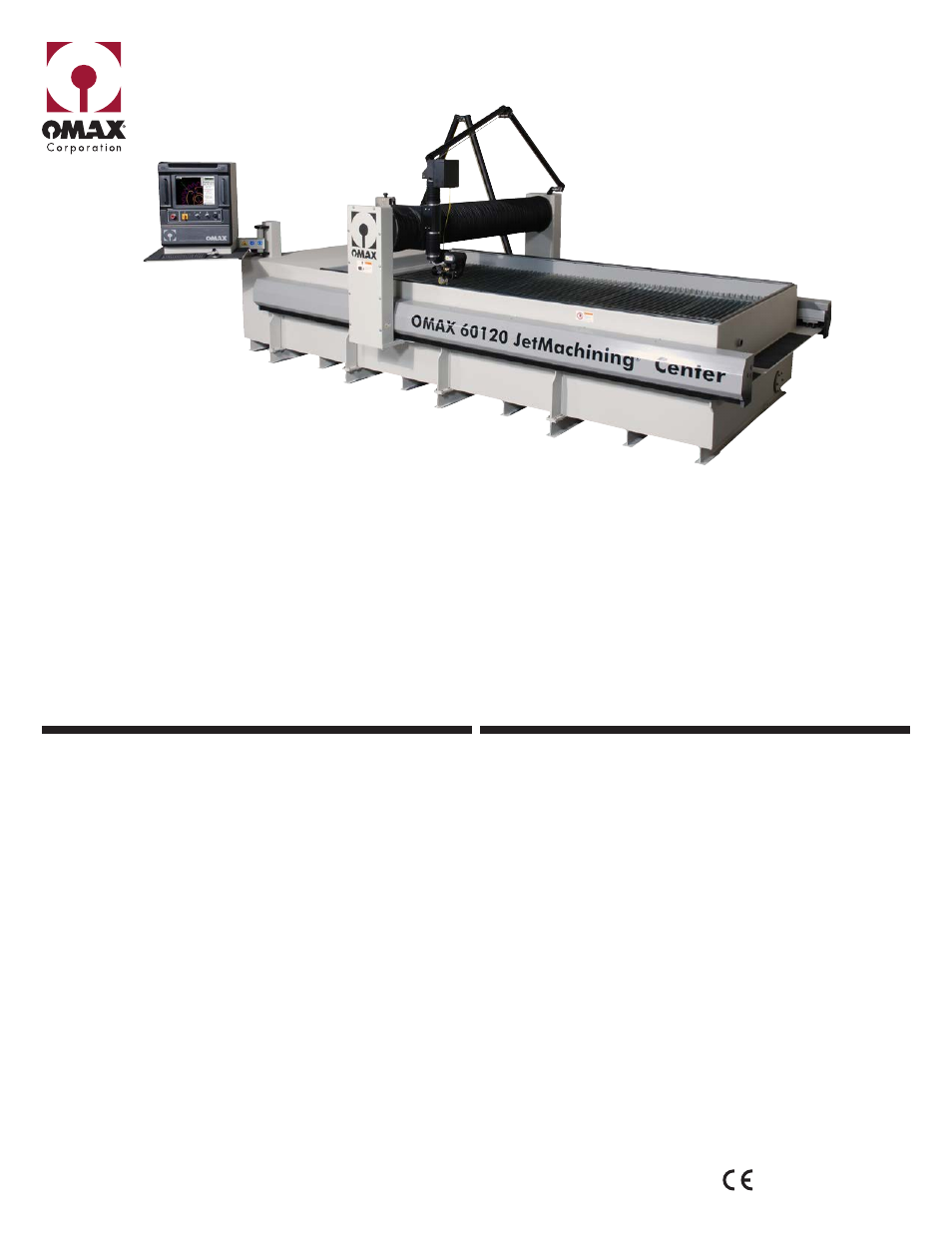

OMAX 60120 JetMachining Center User Manual

Features benefits

OMAX 60120 JetMachining Center

The small-footprint bridge-style OMAX 60120 JetMachining Center is fast and accurate, ideal for a wide range of machining

needs, with one of the lowest cost per part in the industry. The large table can cut stock up to 5’ x 10’, creating complex parts out

of almost any material. Challenging hard, reflective, and nonconductive materials can also be cut, making the 60120 a valuable

addition to existing shop capabilities. Accessories such as the Tilt-A-Jet

®

for taper-free edges, A-Jet

®

for 3D cutting, and the Rotary

Axis for 6-Axis machining increase versatility. The easy-to-use Intelli-MAX Software and the 60120 take you quickly from idea to

reality.

FEATURES

BENEFITS

•

Fastest cutting speeds and best precision compared to any abrasivejet in

the industry and is backed by our exclusive Intelli-MAX

®

Software with real

world cutting data

•

Programmable Motorized Z-Axis with a precision OMAX MAXJET

®

5i Nozzle

Assembly can boost cutting productivity and process efficiency

•

Tilt-A-Jet taper compensating abrasivejet cutting head

(available as an option)

•

Patent-pending Intelli-TRAX

®

traction drive inside the X-Axis beams fully

enclosed inside coated steel covers

•

Scissor-style hard plumbing for low maintenance and high reliability

•

Drive system sealed against water, dirt, and grit

•

Highly efficient, industry-proven Generation 4 EnduroMAX

®

Pumps available

up to 100 hp with operating efficiencies up to 90%

•

Rapid Water Level Control for quiet and clean submerged cutting

•

Bulk Abrasive Feed Assembly transports garnet from the assembly’s large

hopper into the Zero Downtime Hopper located at the Motorized Z-Axis

•

Optional Variable Speed Solids Removal System (VS-SRS) designed for

tough industrial use increases uptime through automated solids removal

•

Shipped as a completely pre-assembled and factory-tested system

•

Machines a wide range of materials and thicknesses, from metals to glass

•

Does not create heat-affected zones or mechanical stresses

•

No tool changes and minimal fixturing reduces setup by 50% or more

•

No additional water required for pump cooling

•

Small, efficient footprint for minimal floorspace utilization

•

Leaves behind a satin-smooth edge, reducing secondary operations

•

No noxious gases, liquid and oils used in, or caused by, the machining process

•

EnduroMAX pump technology delivers the highest nozzle horsepower in the

industry for faster and more efficient cutting

•

Completes most work below 80 dBA at one meter for submerged cutting

•

Environmentally “green” system with quiet and clean operation with low

electrical consumption

•

Highly robust and reliable pump design capable of over 1000 hours

between maintenance

PRECISION ABRASIVE WATERJET SYSTEMS

60120

Made in the USA

WWW.OMAX.COM