OMAX Material Holding Kits User Manual

Omax, Material holding kits

PRECISION ABRASIVE WATERJET ACCESSORIES

Accessory Specifications

Material

Holding Kits

OMAX

®

Material Holding Kits

Material Holding Kits

Standard Features

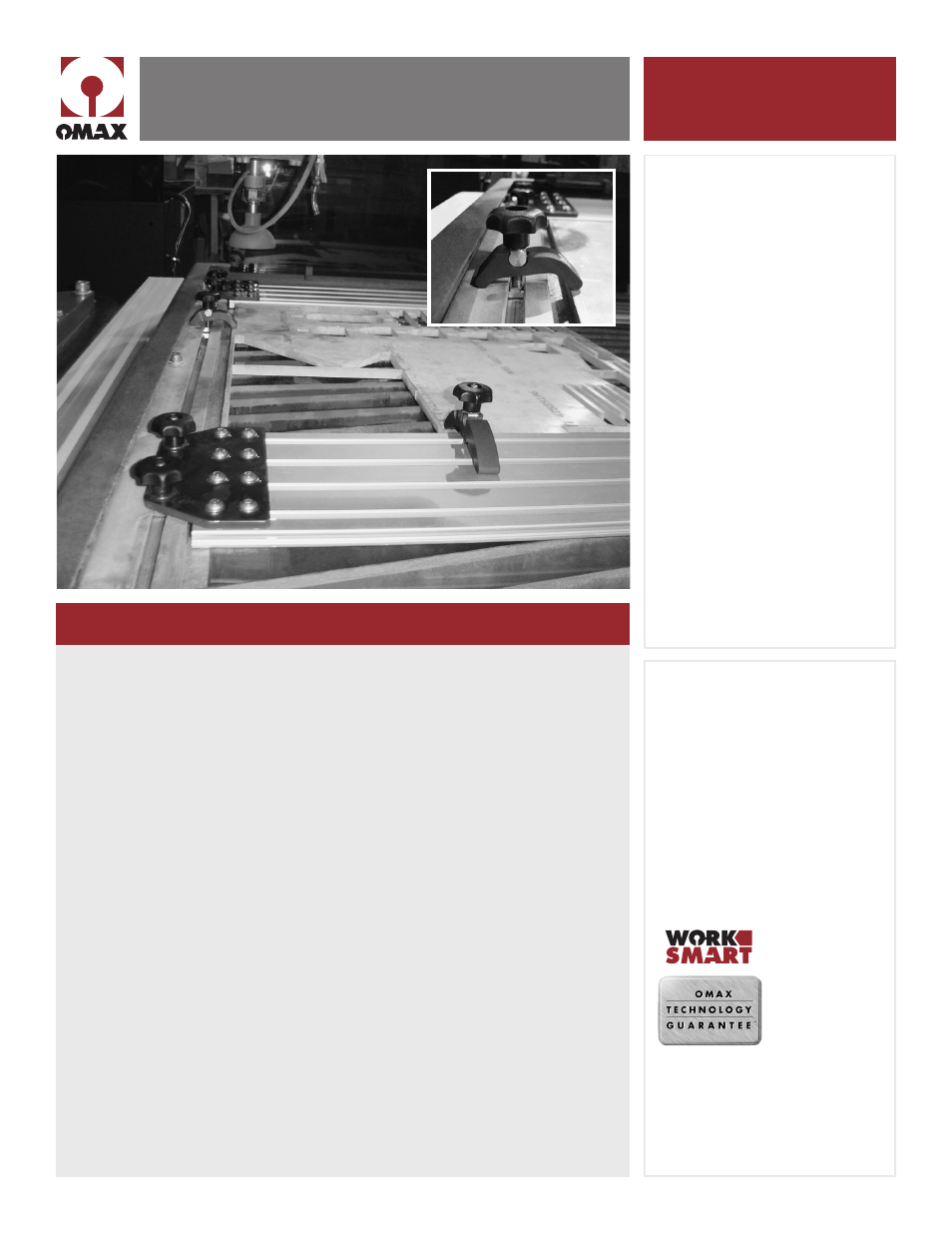

•

Each kit is customized to fit your

specific OMAX JetMachining

®

Center

•

Clamps apply pressure to hold stock

in place

•

Easy to adjust vertical load clamps

can be positioned anywhere on tracks

•

Y-axis tracks can be placed in infinite

locations along the X-axis tracks

•

Track components are made from

anodized aluminum

Benefits

•

Prevents unwanted work piece move-

ment and scrapped parts

•

No machine modifications required

•

Reduces material setup time

•

Expandable design can incorporate

additional clamps or Y-axis tracks

•

Track components are built for

long life in the abrasive waterjet

environment

Secure material in place as you accurately cut

parts on your abrasive waterjet.

Designed specifically for your machine size, each

Material Holding Kit includes track assemblies

and vertical load clamping arms. The kit mounts

into the waterjet slat bed with two X-axis tracks,

two Y-axis tracks, four short vertical load clamps,

and four long vertical load clamps.

C o r p o r a t i o n

OMAX Corporation

21409 72nd Ave South, Kent, WA 98032

253-872-2300

tel

253-872-6190

fax

1-800-838-0343

toll-free

WWW.OMAX.COM

website

Printed in the U.S.A © October 2010 All rights reserved. S-0050

About OMAX

OMAX has the industry leading patented

abrasivejet controller with a built-in

expert system. Our exclusive “Compute

First-Move Later” motion control system

automates most programming and tool

setup work, virtually eliminating the need

for extensive operator training. Plus,

with free OMAX Intelli-MAX

®

Software

upgrades for the life of the machine and

our ongoing commitment to advance

the efficiency of our technology and soft-

ware, OMAX saves you time and money.

The OMAX Technology

Guarantee entitles you, as

the original owner, to free

OMAX software upgrades

for the life of the machine.