OMAX DualBRIDGE System User Manual

Dualbridge, Omax dualbridge, Features

ACCESSORIES

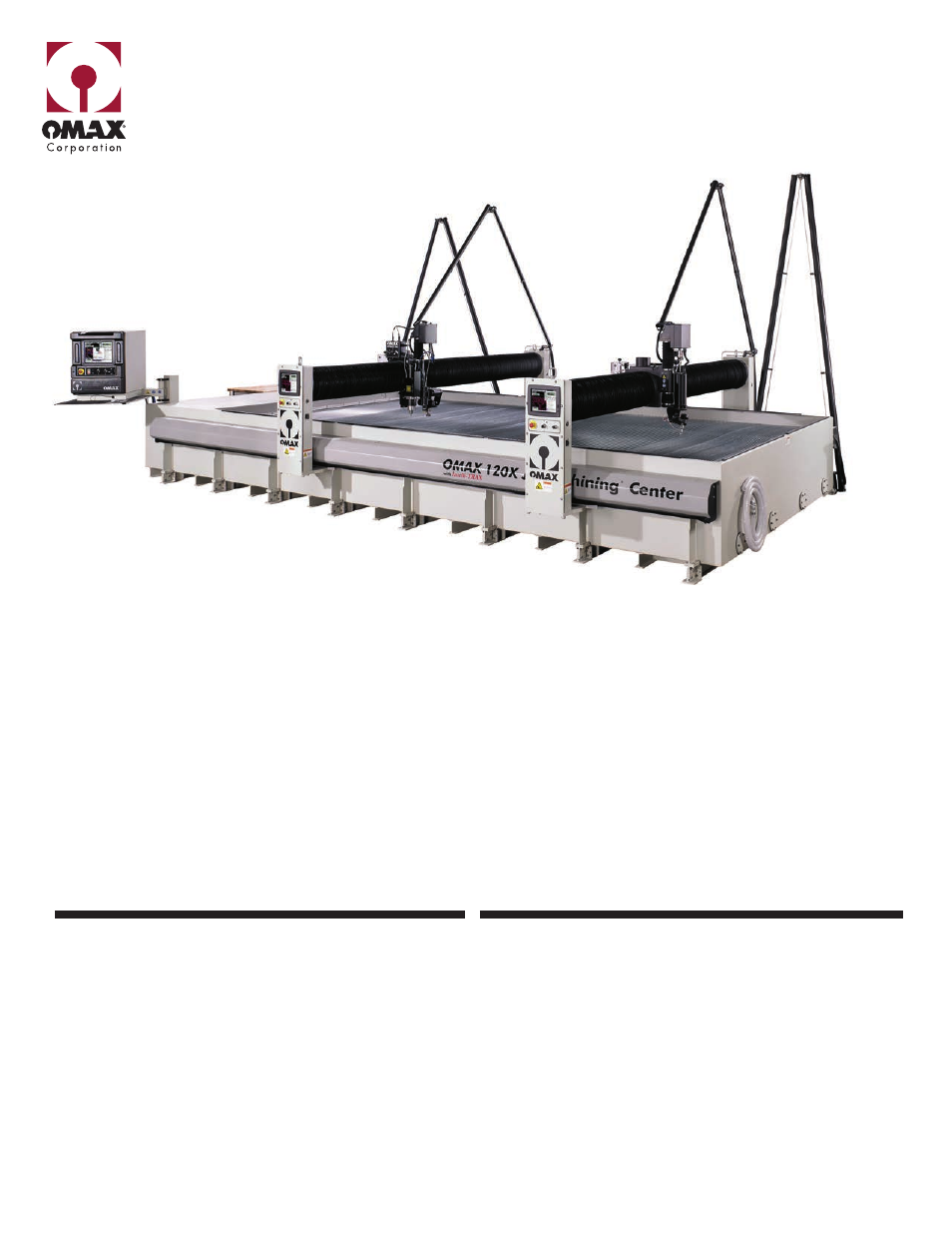

DUALBRIDGE

Made in the USA

WWW.OMAX.COM

FEATURES

•

Each bridge has the same precision as the standard single

bridge OMAX JetMachining

®

Center

•

Automatic bridge collision detection

•

Each bridge can use any of the precision OMAX cutting head

options for maximum versatility

•

You can have different accessories on each bridge, e.g.,

a Tilt-A-Jet

®

on one bridge and an A-Jet

®

on the other bridge

•

Up to four cutting heads on one machine

OMAX DualBRIDGE

Significantly increase productivity with the addition of a second bridge: simultaneously cut separate jobs on a single bed with a

single operator. Available on the 80X Series, 120X Series and 160X Series, the OMAX DualBRIDGE option is ideal for high-

output, high-capacity jobs, or shops with limited facility space. Retrofittable to existing 80X Series, 120X Series, and 160X

Series, two sets of the Intelli-MAX

®

Software Suite on two computers control each bridge autonomously, allowing for two discrete,

independent cutting jobs to take place simultaneously.

BENEFITS

•

Eliminate down times & setup times: With a DualBRIDGE System

you don’t need to stop cutting to load or unload material

•

Redundancy increases productivity: one bridge can continue cutting while the

other undergoes annual inspection

•

Can use both bridges to cut one large part at the same time, greatly reducing

cutting times

•

Small footprint: all the features of a second waterjet machine for

the space of a pump

•

Acquire the fastest cutting configuration with multiple cutting

heads and pumps on one machine