Electronics 590 User Manual

Page 4

4

1. Introduction

This instruction manual covers the MagnaValve models listed in Table 1. A pre-Amp is used

to provide a flow rate signal and transmit it back to the FC Controller as a 0-5 Vdc analog sig-

nal with ±10% accuracy.

Custom calibrations may be used when special conditions prevail; however, we recommend

the standard ranges listed above be used whenever possible because all production valves

are pre-calibrated to the standard ranges shown. An emergency request for a spare Magna-

Valve calibrated to standard range is usually handled within 24 hours. A non-standard cali-

bration may require one week to allow access to the calibration.

2. Theory of Operation

The MagnaValve is a magnetic valve used to control the flow rate of steel shot used in shot

peening and abrasive blast cleaning machines. There are no moving parts in the Magna-

Valve. A strong permanent magnetic field holds the shot. Application of power from the Model

FC controller will cancel the magnetic field and allow shot to flow. The valve is pulsed at eight

times per second (8 Hz) to modulate the flow rate. A special sensor is located in the lower

section of the MagnaValve (or in the 599-5.0 sensor mounted below the MagnaValve for hy-

brid installations) to detect the actual shot flow rate. The sensor signal is processed by the

pre-amp and then sent to the FC controller for feedback information.

A valve driver module is used at each valve to precisely regulate the cancellation current to

assure zero residual magnetic field. The valve driver module is factory set at an amperage

value listed on the valve driver module and does not require any customer adjustment.

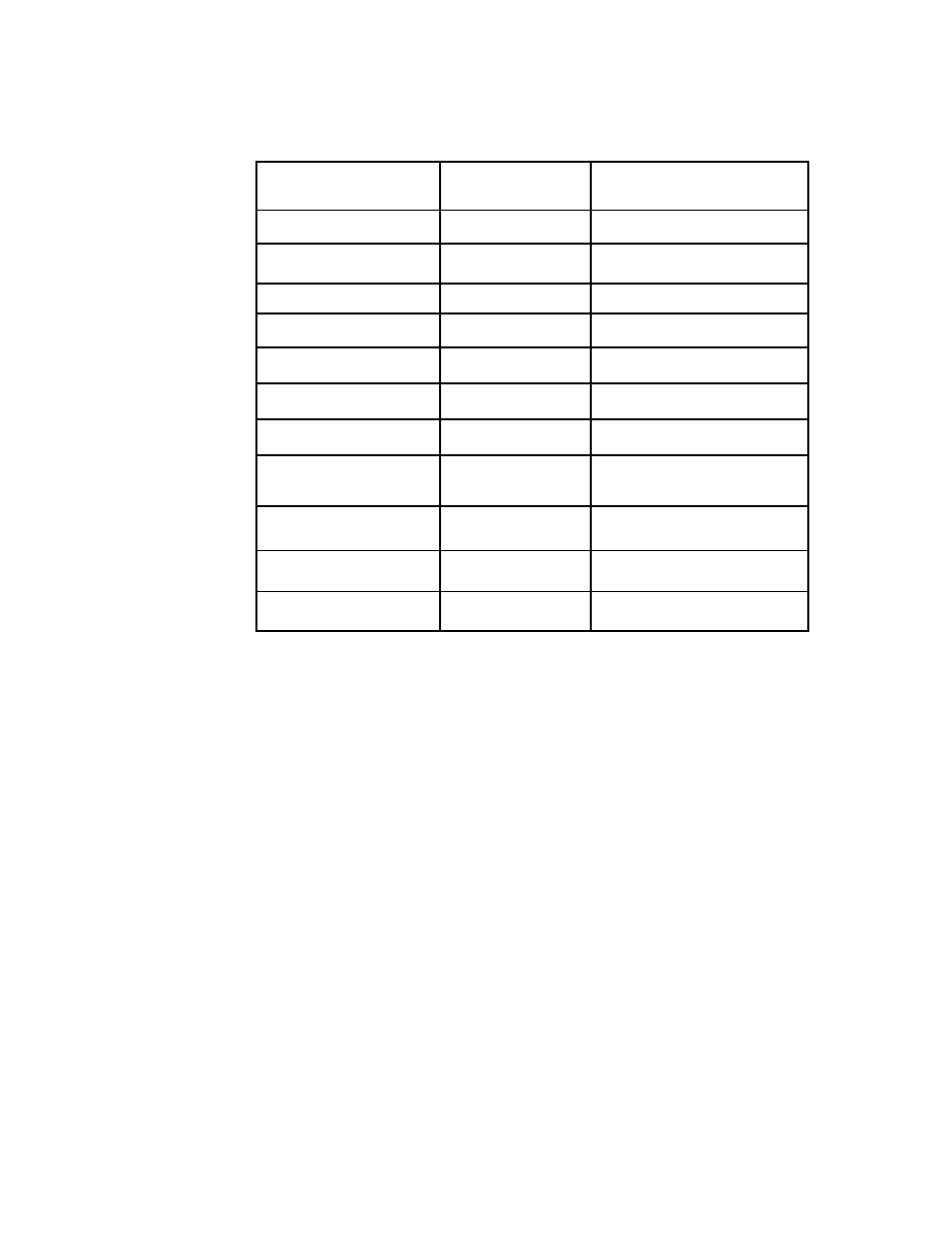

Valve Model

Maximum Flow

Rate (Lb./min)

Operating

Range (Lb./min)

250-N 700 70-700

500-N 1200 120-1200

577 2 .2-2

578 20 3-30

579 100 10-100

580 200 20-200

590 300 30-300

VLP

599-5.0 Sensor

1,000 100-1000

LP

599-5.0 Sensor

1,999 200-2000

1577 2

.2-2

1579 100 10-100

Table 1 MagnaValve Models