Chain and paddles, T if necessary – Grain Systems Bucket Elevtors, Conveyors, Series II Sweeps PNEG-1128 User Manual

Page 29

6. Installation

PNEG-1128 Chain Loop System without Controls

29

Chain and Paddles

The paddles are attached to the chain with 5/16" x 1" serrated flange bolts, flat washers and locking nuts.

Make sure that the slots in the chain paddle brackets are oriented as shown in

The head of the bolt should be inside the “V” shaped chain paddle bracket and the washer and nut

should be against the face of the plastic paddle. Make sure all hardware is tightened properly to a

torque of 20 ft. lbs.

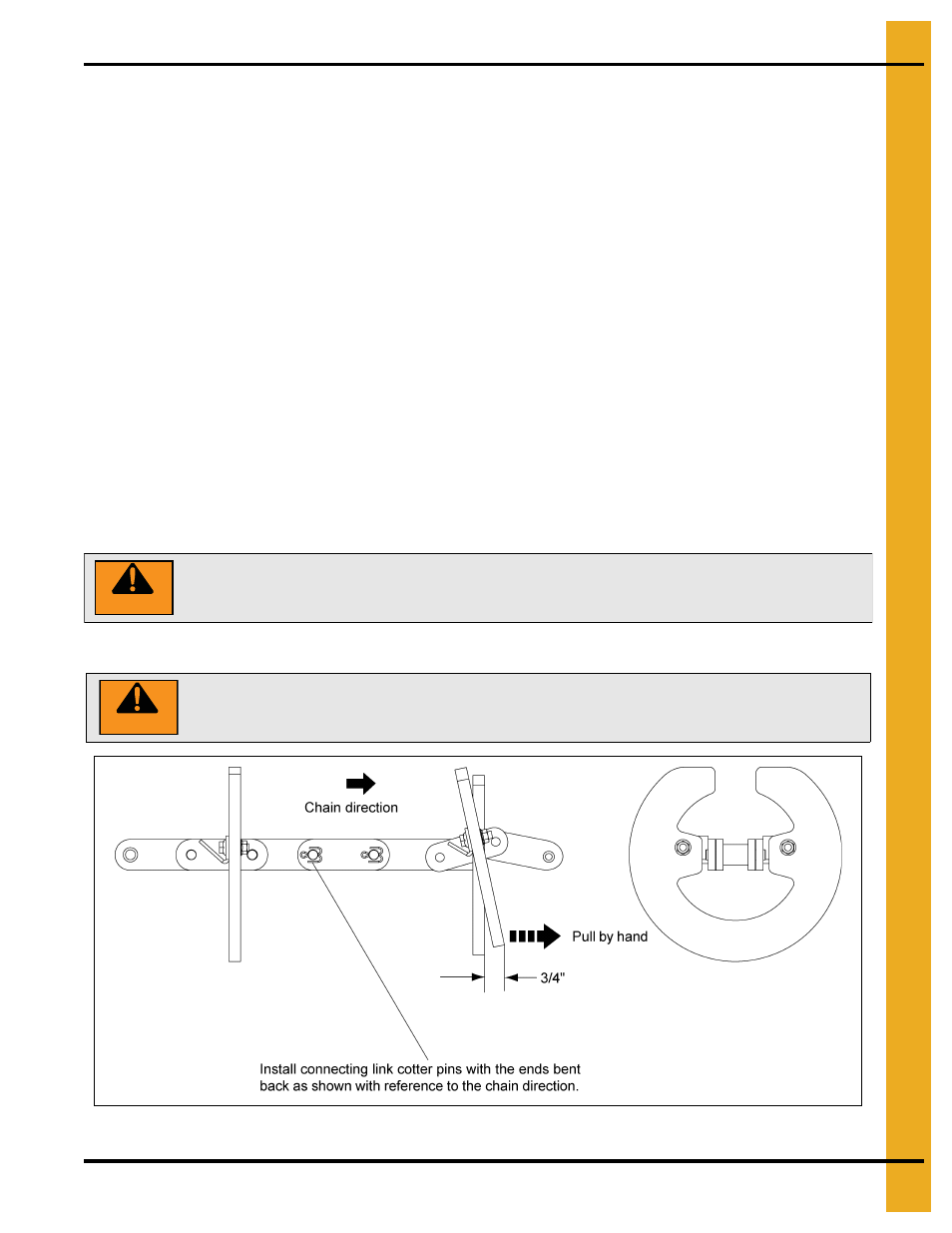

The chain is shipped in 10' lengths and needs to be spliced as shown in

. Make sure

to bend the ends of the cotter pins as shown to prevent them from working loose and causing the chain

to break.

Use an electrical fish tape or wire to pull the chain through the tube assembly. It is possible for the chain

to twist a full 360° during this process. Visually check the chain through open inspection covers at the

discharge gates and openings for wells to make sure that this has not happened.

Adjust the tightening screws in the inspection corner all the way up and connect the final chain link through

the access door in the inspection corner after removing as much chain slack as possible. Tighten the chain

by turning the adjusting screws clockwise; adjust each side equally to keep the sprocket shaft square with

the housing. Remove chain links if there is not enough travel in the adjusting screw to tighten the chain.

Make sure that the sprocket shaft is square to the housing by measuring the shaft position on both sides

of the housing.

The chain should be tightened until the paddles are nearly rigid on the chain. The tips of the paddles

should only move 3/4" when grabbed and pulled by hand.

Check and re-tension the chain after the system has been trial run while empty.

Figure 6L

WARNING

Make sure all shields and safety guards are in place before restoring power.

WARNING

Turn OFF and lock out the main power source BEFORE removing any

inspection covers or shields.