Information, Chapter 3 information, Chain loop system information – Grain Systems Bucket Elevtors, Conveyors, Series II Sweeps PNEG-1128 User Manual

Page 13

PNEG-1128 Chain Loop System without Controls

13

3. Information

Chain Loop System Information

A Chain Loop System is a chain and paddle conveyor moving through a round housing. A loop system

allows you to do total loading and unloading with a single drive. Chain Loop Systems will handle a wide

range of free flowing materials. They are primarily intended for grain and grain products. They will move

material into and out of grain storage structures, vehicles, dryers and other facilities with ease and

gentleness. The Chain Loop System is well suited for blending materials while being transferred from one

storage unit to another.

The height and length of the system is limited by the combined horsepower required to move the grain.

The vertical Chain Loop System requires greater horsepower per foot, so the taller units will be more

limited in the overall horizontal length. System lengths of several hundred feet are common. However,

relatively small systems to accomplish more specific tasks are also available.

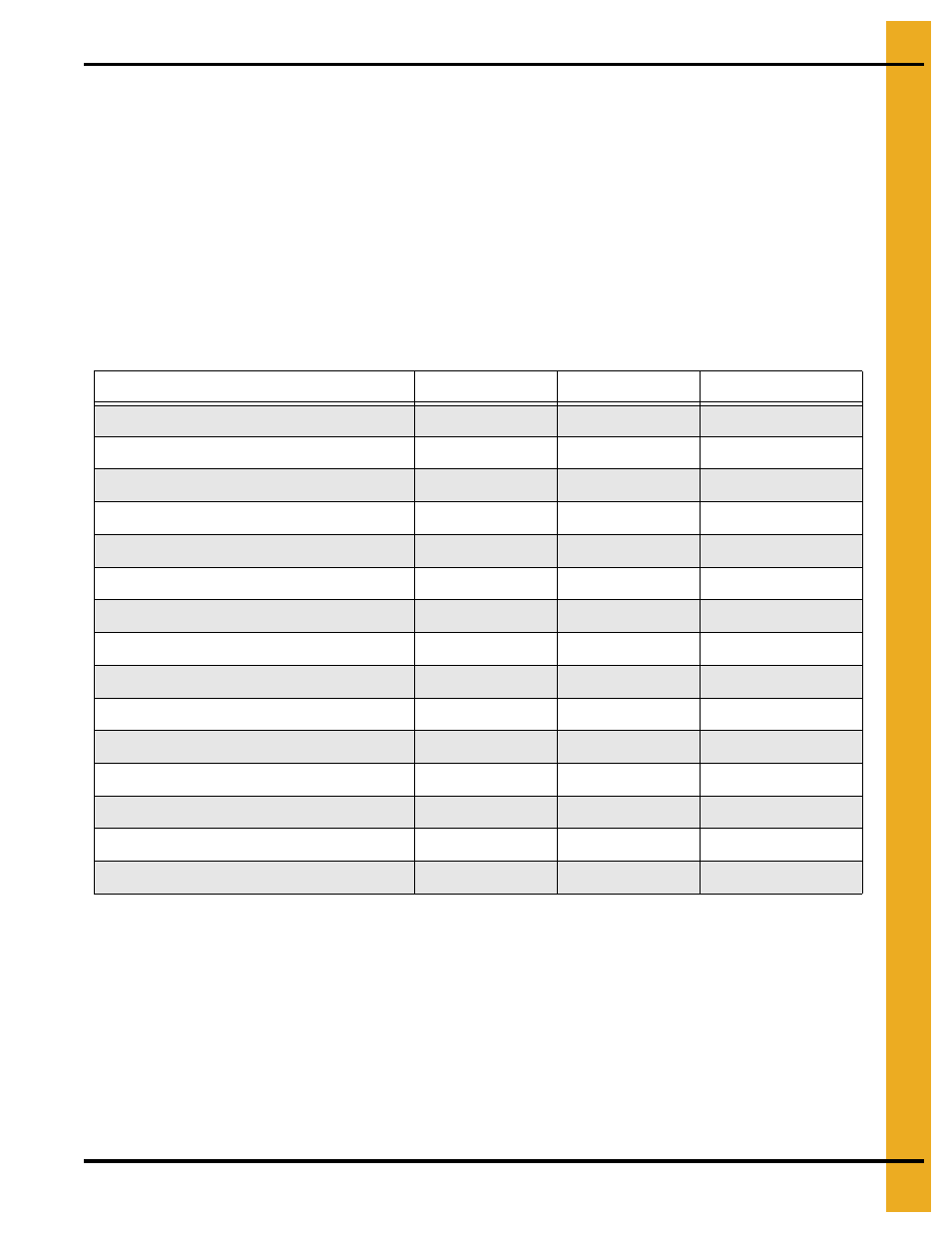

Chain Loop System Specifications

* Clean dry grain

8"

10"

12"

*Maximum capacity in BPH (Tons/Hr)

4000 (100)

6000 (150)

1000 (250)

Chain travel in FPM (Meters, Min)

325 (99)

325 (99)

400 (122)

Head shaft RPM

94

94

83

Corner housing thickness, galvanized (mm)

7 Ga. (4.8)

5 Ga. (4.8)

3/16" (4.8)

Galvanized tubing wall thickness (mm)

12 Ga. (2.7)

12 Ga. (2.7)

10 Ga. (3.47) 7 Ga. (5)

Paddle thickness (UHMW) (mm)

3/8" (9.5)

1/2" (12.7)

1/2" (12.7)

Corner shaft diameter (mm)

2" (50.8)

3" (76.2)

3-7/16" (87.3)

Conveyor chain

81XHH

81XHH

81XHH

Conveyor sprocket

16 Tooth

16 Tooth

22 Tooth

*Power requirements

Per foot vertical (KW/M)

0.35 (0.86)

0.5 (1.22)

0.75 (1.84)

Per foot horizontal (KW/M)

0.08 (0.19)

0.11 (0.27)

0.18 (0.44)

Weight per foot lbs (KG/M)

Empty

12 (17.9)

15 (22.3)

24 (35.8) 30 (44.7)

Full of 56 lb. per bu. material

28 (41.7)

40 (59.5)

59 (88) 65 (97)