Fan blade removal and installation, Fan operation – Grain Systems PNEG-010 User Manual

Page 20

6. Fan Operation

20

PNEG-010 Vane Axial Fan

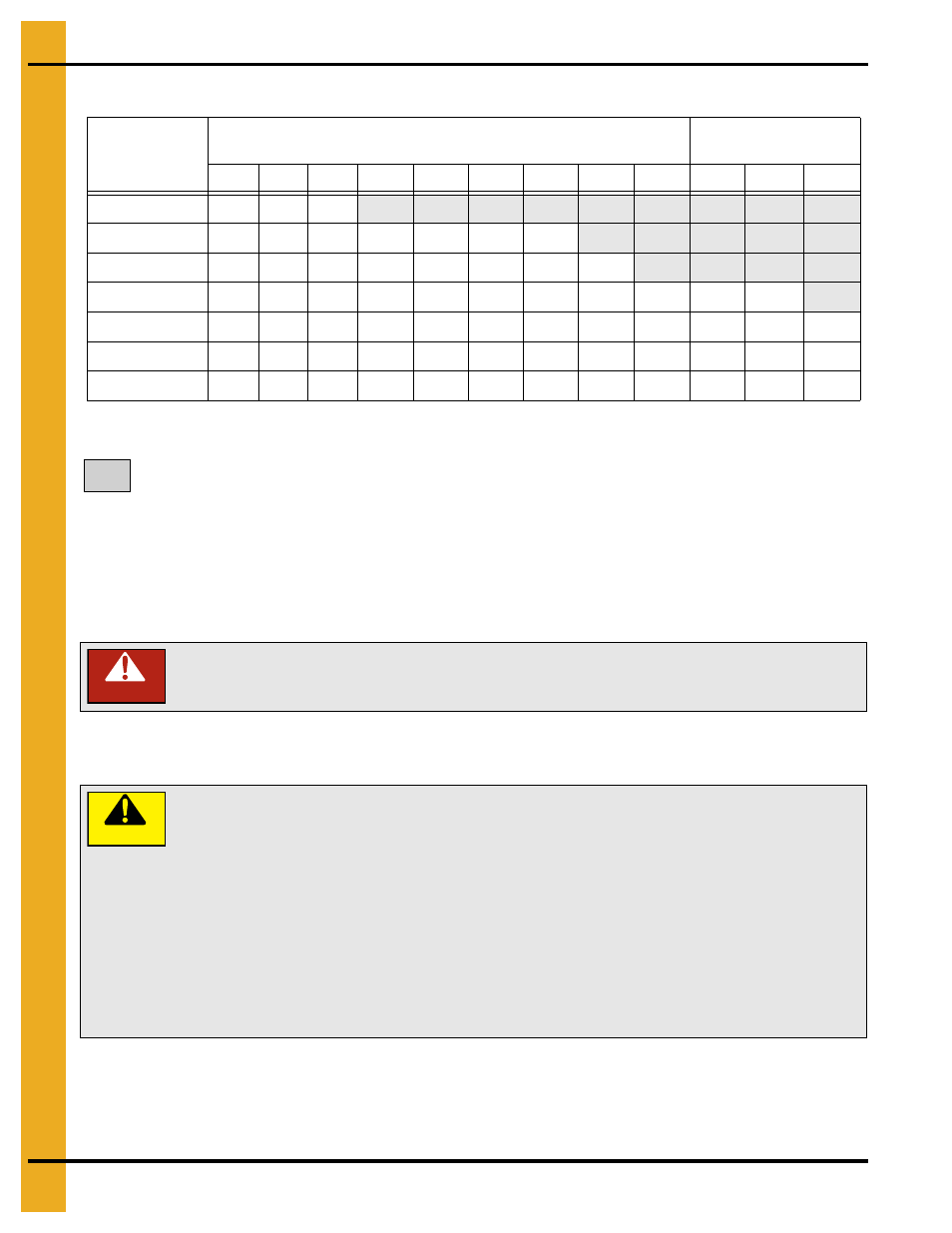

Approximate Hours of Fan Time to Change Bin Temperature

1. Bushels are rounded and approximate.

2. The hours required are based on clean grain. High moisture grain and grain containing fines or foreign material will

require more time to complete the air change.

3. Not Recommended: Bins in the NR range, may require fan(s) of a different size to get the cool time into the

accepted range.

4. Bins requiring more than 100 hours of aeration to totally change the temperature may require continuous aeration at

about 1/10

th

CFM per bushel or some other acceptable method.

Fan Blade Removal and Installation

The fan blade is secured to the motor shaft by the use of a taper-lock bushing, motor shaft key and

cap screws. The size, quantity and torque of cap screws required will depend on the model of the fan.

Fan Size

HP

Bin Diameter Approximate 22' to Eave-Approximate Hours

of Fan Time Required

Approximate 32' to Eave

18

21

24

27

30

33

36

42

48

36

42

48

1

73

79

90

NR

NR

NR

NR

NR

NR

NR

NR

NR

1.5

56

61

65

66

76

82

92

NR

NR

NR

NR

NR

3

44

51

52

57

63

69

78

93

NR

NR

NR

NR

7

38

42

44

47

52

56

61

71

81

79

93

NR

10

35

37

41

42

45

49

53

62

71

72

82

92

15

30

32

35

39

40

42

45

54

63

62

70

80

Approximate BU

4500

6500

8500

11000

13500

16500

19500

27000

35500

28000

38500

50500

DANGER

Always disconnect and lock out power before working on or around fan.

CAUTION

Although the taper-lock method of retaining the blade onto the motor shaft is

very simple and obvious, it is essential that the following points be read

carefully and fully understood, as improper installation can result in serious or

fatal injury caused by a loose, fast flying blade.

THREADED BUSHING HOLES: The threaded holes within the bushing are

provided for disassembly purposes only. Do not attempt to use these holes for

re-assembly, as they will not allow the parts to become locked onto the shaft,

thereby causing an extremely hazardous operating condition.

CLEARANCE HOLES: When reassembling parts, the cap screws must be

installed through the UNTAPPED.

NR