Fuel connection, Chapter 8 fuel connection, Liquid propane (lp) – Grain Systems PNEG-338 User Manual

Page 18: Liquid draw, Ammonia tanks, Oil or water in tanks

18

PNEG-338 Portable Dryer Installation and Towing

8. Fuel Connection

Liquid Propane (LP)

Liquid Draw

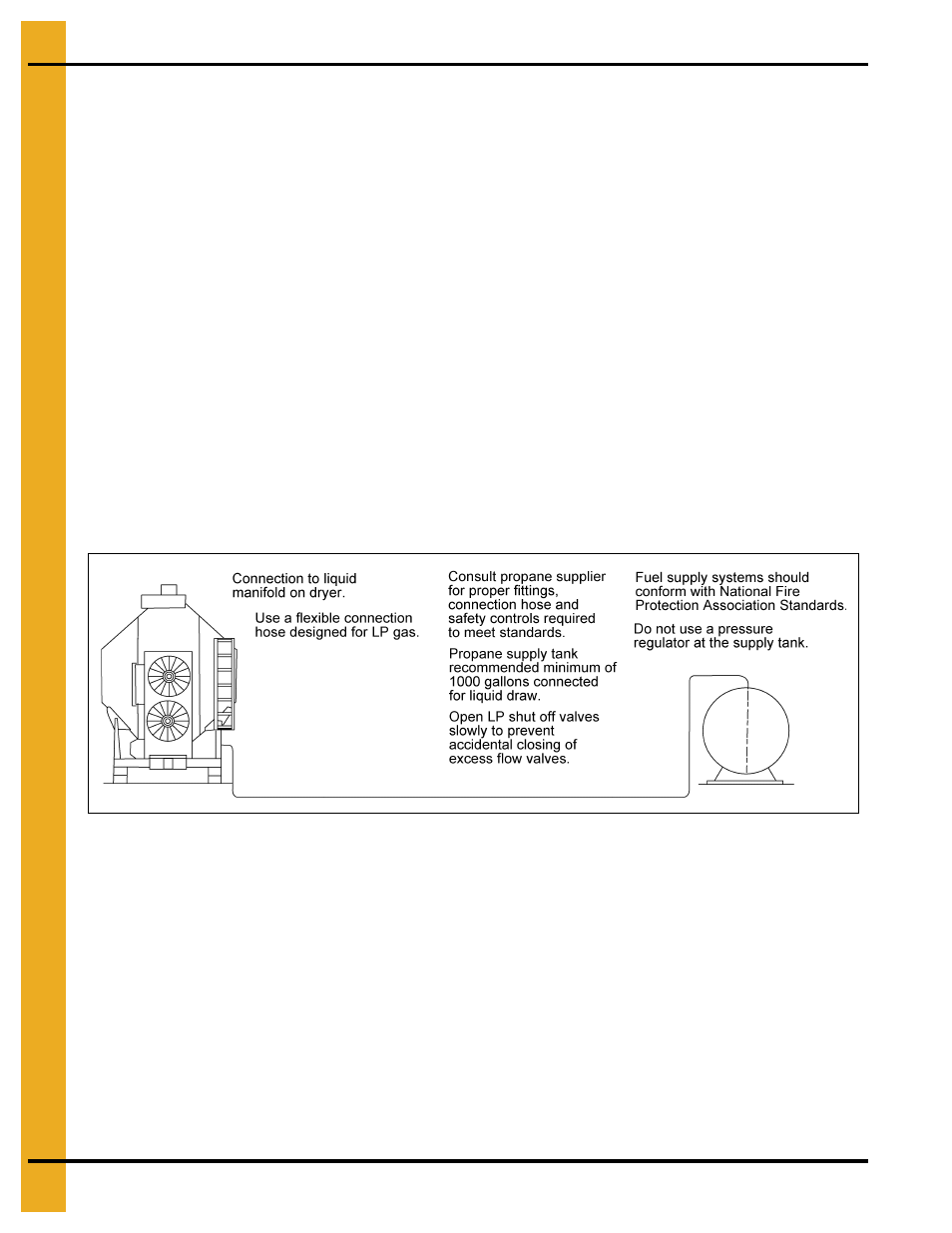

The dryers have internal vaporizers and are designed to operate on liquid draw from the supply tank. The

tank should be 1000 gallons or larger and should not have a regulator mounted to it. The connection to

the dryer should be with a flexible hose designed for LP gas,

for proper size.

Consult your LP gas dealer for proper fittings, connection hose and safety controls required to meet local

standards and to conform with National Fire Protection Association standards. The piping train on the

dryer includes strainer, pressure relief valve, electronic safety shut off valve (on some models) and a

pressure regulator between the vaporizer and burner.

Ammonia Tanks

Do not use tanks which have previously been used for ammonia or fertilizer solutions. These substances

are extremely corrosive and will damage fuel supply and burner parts.

Oil or Water in Tanks

With liquid draw from the supply tank, any water or oil present in the tank may freeze in the pipe train or

controls causing damage. To make sure the tank is free of moisture, it can be purged with methanol. Avoid

tanks which may contain an accumulation of oil or heavy hydrocarbon from long use on a vapor withdrawal

system.

Figure 8A Grain dryer connected to a liquid propane tank.

See Fuel Specification Chart

on Page 19

for recommended

line use.