Hoisting, Chapter 16 hoisting, Hoisting recommendations – Grain Systems Tanks PNEG-603 User Manual

Page 51

PNEG-603 4" Commercial Hopper Tank

51

16. Hoisting

Hoisting Recommendations

RECOMMENDATIONS FOR HOISTING COMPLETED TANK ONTO HOPPER BOTTOM STRUCTURE.

(ALL PARTS MENTIONED IN THIS SECTION ARE NOT FURNISHED.) A crane is normally used to lift

the tank and place it on top of the substructure. Technique of hoisting of the complete tank on the hopper

structure is in large part based on personal experience, equipment and manpower. The following

recommendations are intended as a guideline only.

1. Before lifting the tank the following should be checked:

a. The columns and substructure should be checked for levelness and verified plumb and leveled

if necessary.

b. Final ladder and safety cage and door locations should be determined and clearance at these

locations verified.

c. Proper provisions should be made for safe working platforms around the top of the substructure.

2. Lifting technique are largely influenced by personal experience and equipment capacity however

general recommendations as follow:

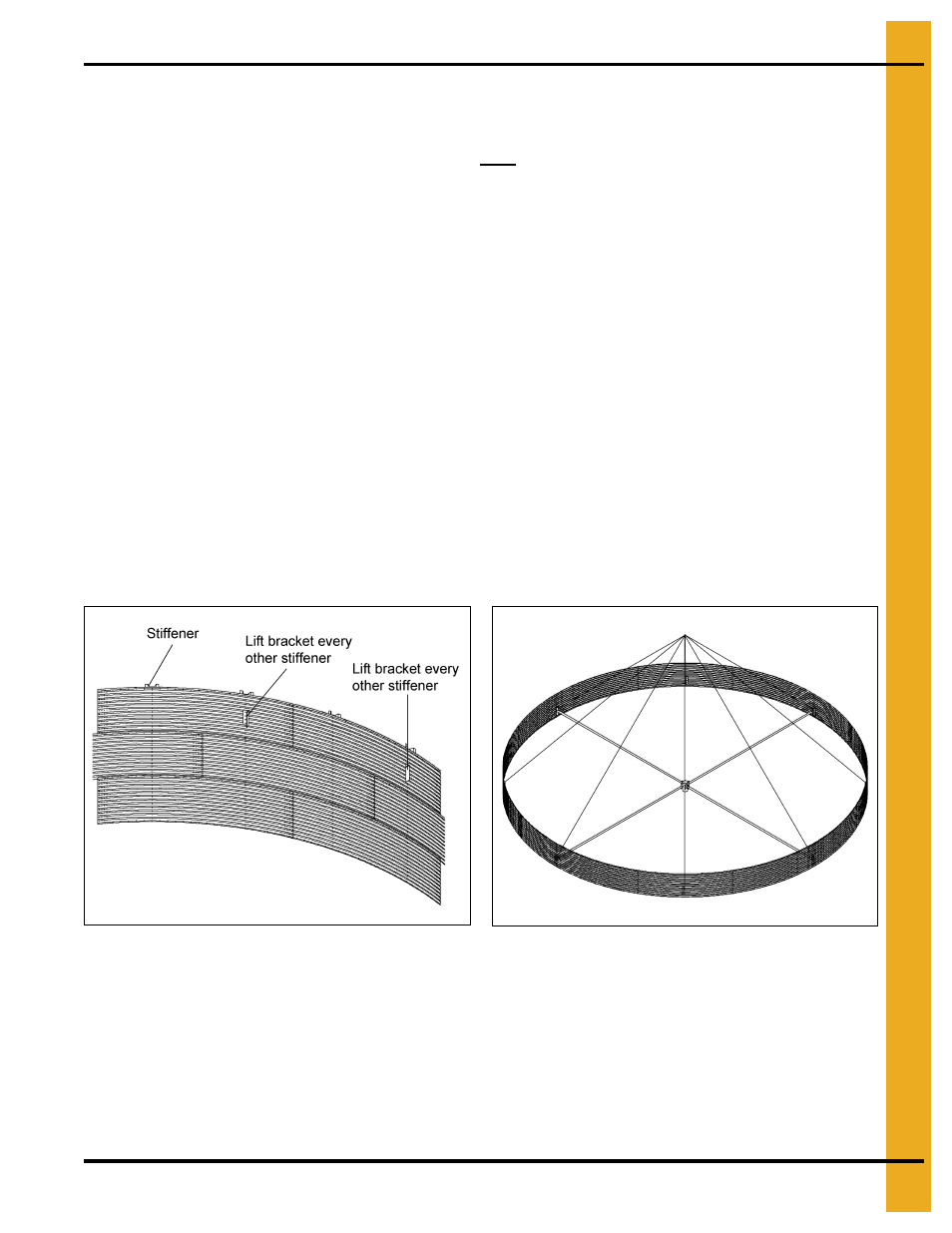

a. Lifting brackets should be attached to the stiffeners. At least one bracket per sidewall sheet

should be used. These would typically be attached in the third ring from the bottom of the tank.

Brackets should attach to a minimum of four (4) bolts through the stiffener. Attach cables to the

lift brackets and to the crane hook, which has been lowered through the center ring opening.

Cables should be sized to handle the entire weight of the bin. Make all lift cables of equal length

before the bin is lifted.

Figure 16A

Figure 16B