Rough Country 696N2 User Manual

Page 7

REAR BRAKE LINE INSTALLATION INSTRUCTIONS

1. Next remove the E-clip holding the brake line on at the

frame mount. This will be extended with a bracket.

2. Bolt the z drop bracket to the frame using the supplied

5/16” hardware and tighten using a 1/2” wrench. Install

the brake line into the new bracket with the stock e-clip.

SEE PHOTO 1.

TRANSFER CASE DROP INSTALLATION INSTRUCTIONS

1. Position the floor jack under the transfer case cross mem-

ber and lightly apply pressure.

2. Loosen and remove the bolt and the nut on stud on the

driver side transfer case cross member.

3. Loosen and remove the bolt and nut on the drivers side

cross member.

4. Carefully lower the transfer case down to the point it clears the stud.

5. Using 2 nuts to form a jam nut on the stud, remove the

stud from the cross member on both sides.

6. Carefully lower the transfer case cross member to allow

clearance for installation of transfer case spacer and

sleeve.

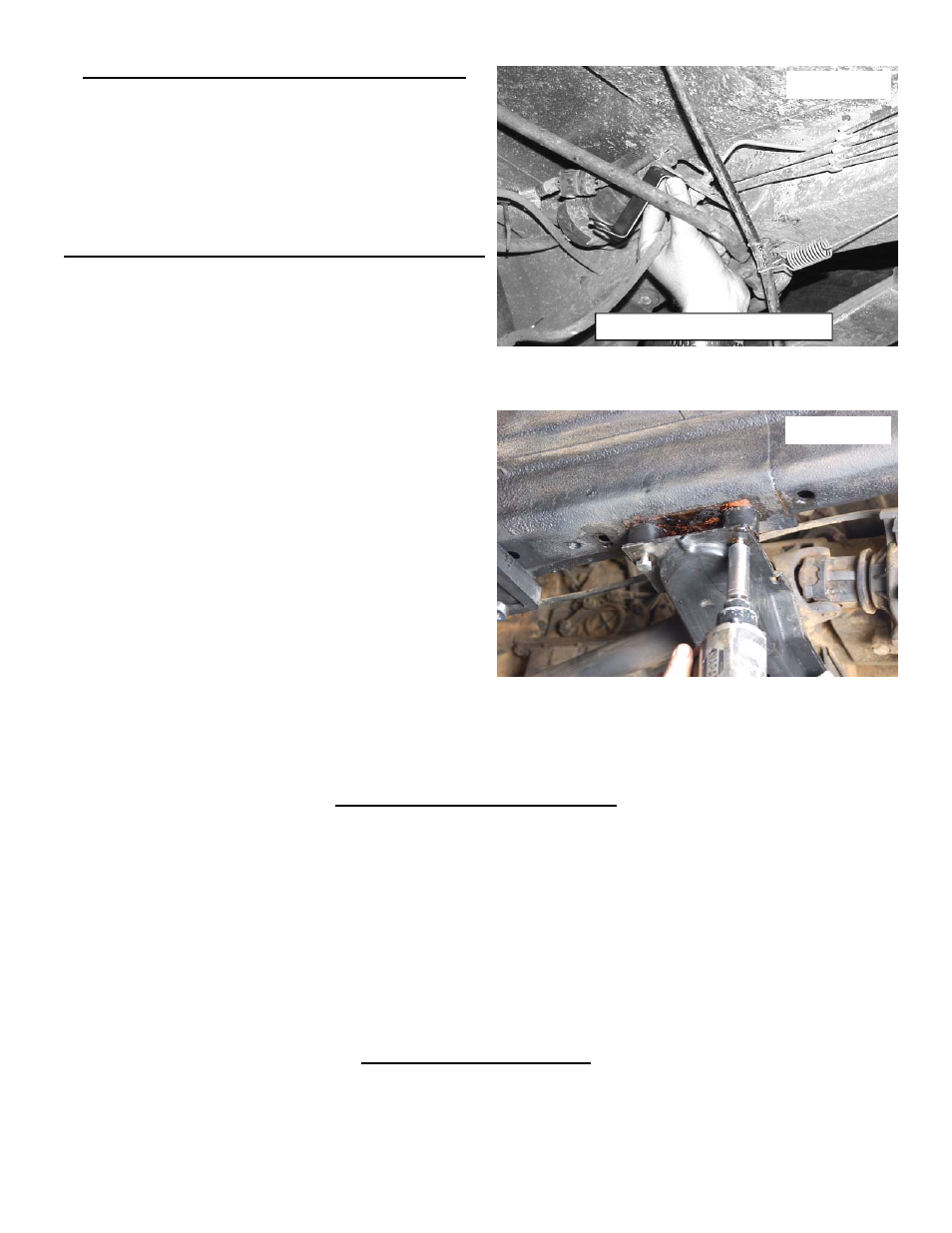

7. Place the spacer between the frame and cross member;

install the new 10mm x 60m bolts through cross member,

spacer and into uni-body. Raise the transfer case and

tighten bolts to 35 ft/lbs. See PHOTO 2.

PHOTO 1

Driver Side Frame Rail Shown

PHOTO 2

POST INSTALLATION INSTRUCTIONS

1. Check all fasteners for proper torque.

2. Check to ensure there is adequate clearance between all rotating, mobile, fixed and heated members.

3. Check steering gear for interference and proper working order.

4. Before driving the vehicle, check to make sure brakes are operating properly and do not need to be blead.

5. Perform steering sweep.

6. Check to ensure brake hoses have sufficient slack and will not contact rotating, mobile, or fixed members. Adjust

lines/brackets to eliminate interference and maintain proper working order. Failure to perform inspections may result

in component failure.

7. Have headlight readjusted to proper settings.

8. Take the vehicle to be aligned to factory specifications by a certified alignment shop.

9. Re torque all fasteners after 500 miles. Visually inspect components and re torque fasteners during routine vehicle

service.

MAINTENANCE INFORMATION

It is the ultimate buyers responsibility to have all bolts/nuts checked for tightness after the first 100 miles and then

every 100 miles. A qualified mechanic must inspect wheel alignment steering system, suspension and driveline systems

at least every 3000 miles

.