Durability, Better built to meet your needs – Milton CAT 966K User Manual

Page 4

Durability

BetterBuilttoMeetYourNeeds

Frames

The robotically welded twopiece structural frame design

provides a rugged and reliable foundation for the machine

that improves stability, performance, and serviceability.

A robust articulating hitch system joins the front and rear

frames improving durability. Enhanced lines routings across

the hitch joint streamline the manufacturing process and

improve reliability and durability.

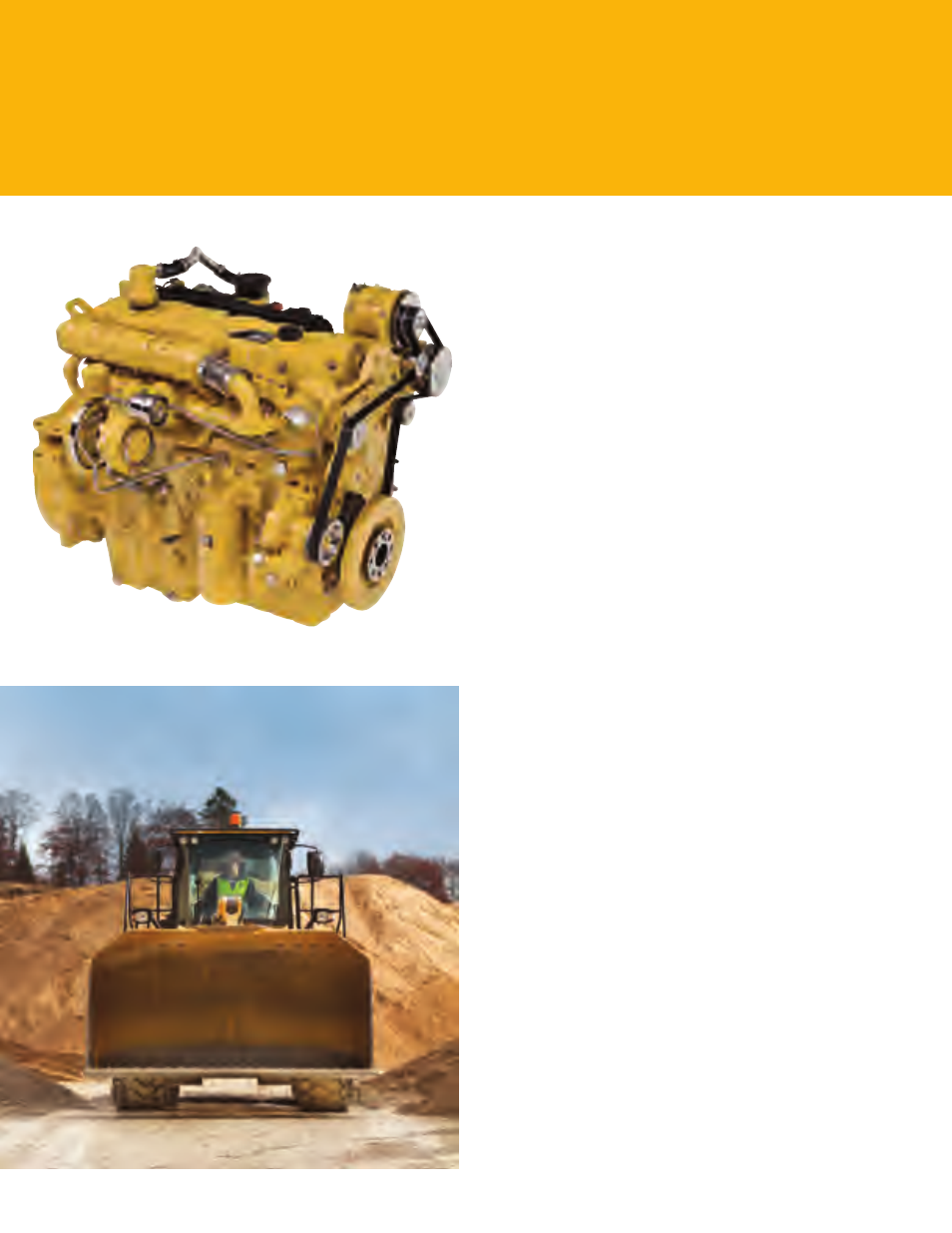

Engine

The new Cat C9.3 ACERT engine was designed to optimize

power density. It uses a combination of technologies to reduce

regulated emissions while ensuring high performance and

excellent fuel efficiency. An upgraded ADEM™ 4 electronic

control module manages the combustion process and a

new highpressure common rail fuel system allows precise

injection timing for a clean, efficient fuel burn. The rugged

Cat Clean Emissions Module is securely rubber mounted

on its own platform above the engine and contains a

Diesel Oxidation Catalyst, Diesel Particulate Filter and

Cat Regeneration System. Regeneration, the process by

which soot is removed from the Diesel Particulate Filter,

is completely automatic and does not interrupt the

machine’s work cycle.

Emissions

The 966K features a Cat C9.3 ACERT engine and a

Cat Clean Emissions Module to deliver the performance

and efficiency that customers demand, while meeting

Tier 4 Interim/Stage IIIB emission standards. The sixcylinder

electronic engine is turbocharged and aftercooled. ACERT™

Technology is a combination of building blocks that includes

electronics, fuel systems, air management systems and

aftertreatment components. The system is optimized based

on engine size, the type of application and the geographic

location in which it will work. The technologies are applied

systematically and strategically to meet high customer

expectations for productivity, fuel effi ciency, reliability

and service life.

Axles

The 966K axles are designed to handle extreme applications

resulting in reliable performance and extended life. The front

axle is rigidly mounted to the frame in order to withstand

internal torque loads and still maintain support for the wheel

loader. The rear axle can oscillate to ±13 degrees helping to

ensure all four wheels stay on the ground providing stability

even in the roughest terrain.

4