980k wheel loader specifi cations, Operating specifications – Milton CAT 980K User Manual

Page 18

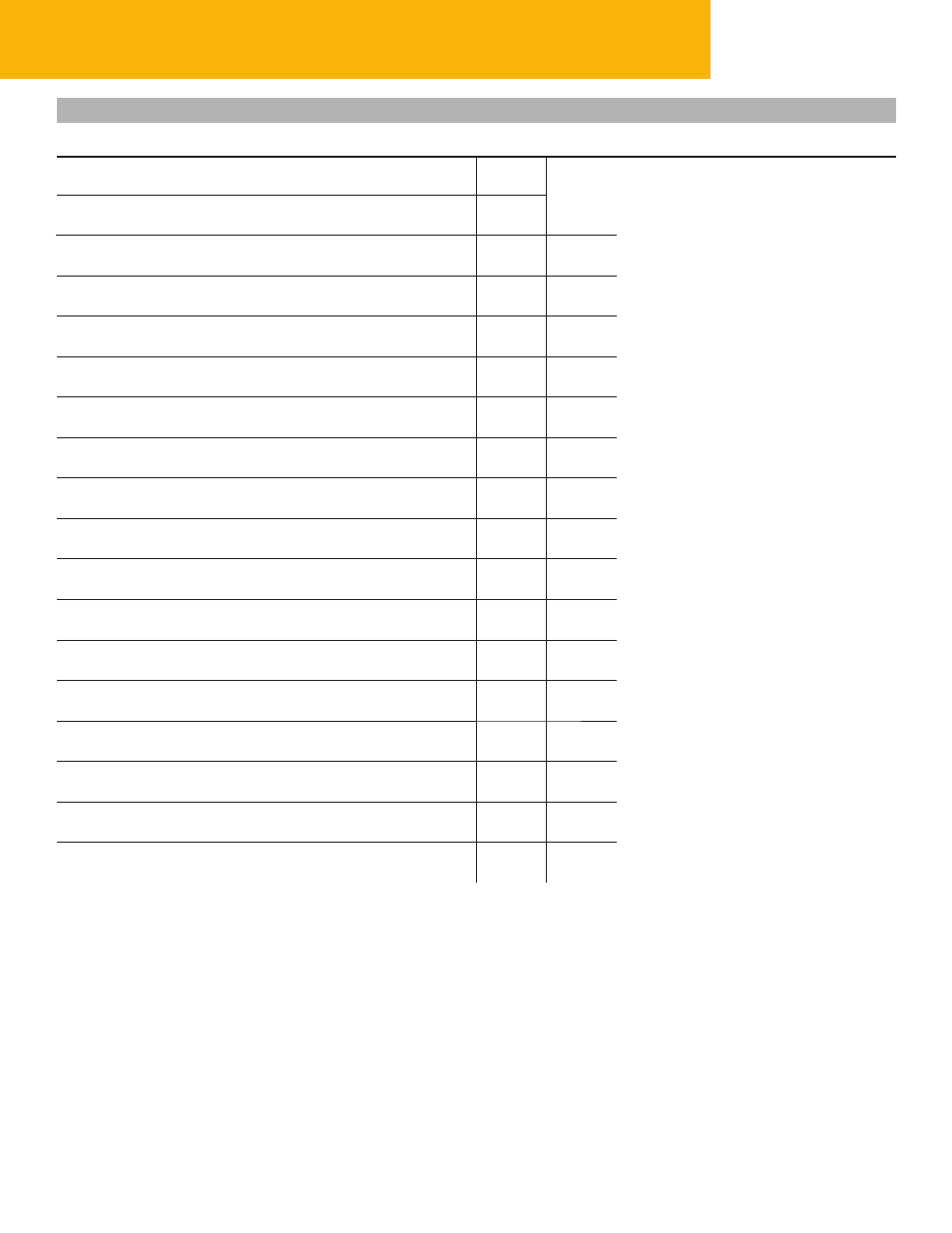

980K Wheel Loader Specifi cations

Operating Specifications

Bucket Type

Coal –

Pin On

Edge Type

Bolt-On

Edges

8.20

10.73

6.47

8.46

3638

11'11"

2917

9'6"

1700

5'6"

3411

11'2"

108

4.2"

9883

32'6"

6536

21'6"

16 234

53'4"

20 819

45,887

22 238

49,012

18 293

40,318

19 567

43,125

186

41,956

31 831

70,156

Capacity – Rated (§)

m

3

yd

3

Capacity – Struck (§)

m

3

yd

3

Width (§)

mm

ft/in

Dump Clearance at Maximum Lift and 45° Discharge (§)

mm

ft/in

Reach at Maximum Lift and 45° Discharge (§)

mm

ft/in

Reach at Level Lift Arm and Bucket Level (§)

mm

ft/in

Digging Depth (§)

mm

in

Overall Length

mm

ft/in

Overall Height with Bucket at Maximum Lift

mm

ft/in

Loader Clearance Circle with Bucket at Carry Position (§)

mm

ft/in

Static Tipping Load, Straight (ISO)*

kg

lb

Static Tipping Load, Straight (Rigid Tire)*

kg

lb

Static Tipping Load, Articulated (ISO)*

kg

lb

Static Tipping Load, Articulated (Rigid Tire)*

kg

lb

Breakout Force** (§)

kN

lb

Operating Weight*

kg

lb

High Lift

Change

in Specs

220

8"

160

6"

201

8"

221

9"

175

7"

–1831

–4,036

–2026

–4,467

–1656

–3,651

–1836

–4,048

3

813

115

253

* Static tipping loads and operating weights shown are based on a machine configuration with Michelin 29.5R25 XLDD1 L4 Radial tires,

full fluids, operator, standard counterweight, standard transmission, cold start, roading fenders, Product Link, open differential axles

(front/rear), power train guard, secondary steering, and sound suppression.

** Measured 102 mm (4") behind tip of cutting edge with bucket hinge pin as pivot point in accordance with SAE J732C.

*** Rock bucket specifications are given on Michelin 29.5R25 XLDD2 L5 Radial tires.

(§) Specifications and ratings conform to all applicable standards recommended by the Society of Automotive Engineers, including

SAE Standard J732C governing loader ratings.

(ISO) Full compliance to ISO 14397-1 (2007) Sections 1 thru 6, which requires 2% verification between calculations and testing.

(Rigid Tire) Compliance to ISO 14397-1 (2007) Sections 1 thru 5.

18