Axles, Tires, Sound – Milton CAT 980K User Manual

Page 15: Service refill capacities, Axles cab service refill capacities

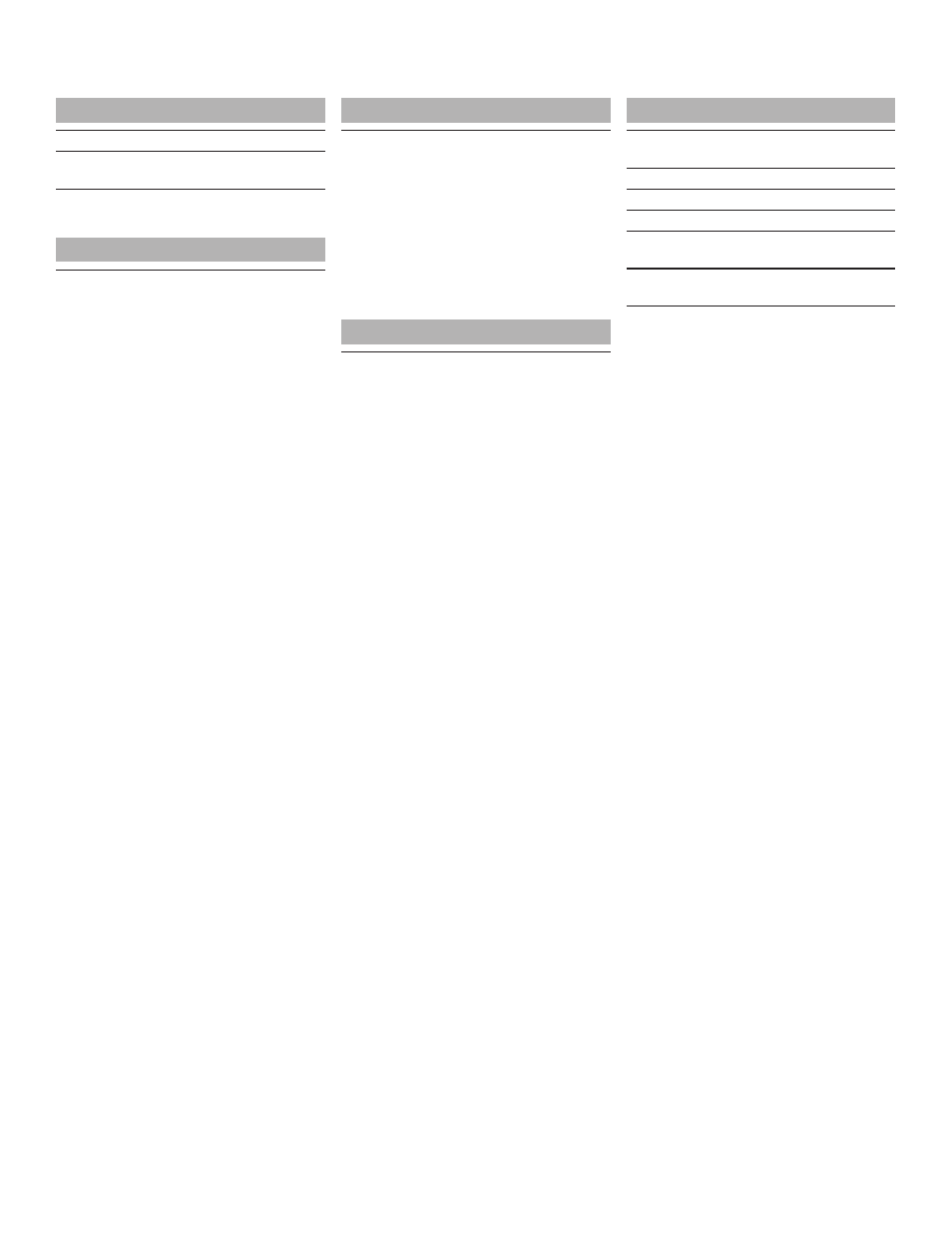

Axles

Cab

Service Refill Capacities

Front

Fixed

Rear

Oscillating

± 13 degrees

Maximum Single-

548 mm

21.6 in

Wheel Rise and Fall

Tires

• Choose from a variety of tires to match

your application.

• Choices include:

29.5R25 VMT BS L3 Radial

29.5-25 SRG LD FS E3/L3 Bias

29.5R25 XHA2 MX L3 Radial

29.5R25 XLDD1 MX L4 Radial

29.5R25 VSNT BS L4 Radial

29.6-25 SDT LD FS L5 Bias

29.5R25 VSDL BS L5 Radial

29.5R25 XLDD2 MX L5 Radial

29.5R25 X MINE D2 MX L5 Radial

• NOTE: In certain applications (such as

load and carry), the loader’s productive

capabilities might exceed the tires’ tonnes

km/h (ton-mph) capabilities. Caterpillar

recommends that you consult a tire supplier

to evaluate all conditions before selecting a

tire model. Other special tires are available

on request.

ROPS/FOPS

Meets SAE and

ISO standards

• Cat cab with a four post integrated Rollover

Protective Structure (ROPS) are standard

in North America and Europe.

• ROPS meets SAE J1040 APR88 and

ISO 3471:1994 criteria.

• Falling Objects Protective Structure (FOPS)

meets SAE J231 JAN81 and ISO:1992

Level II criteria.

Sound

• The sound values indicated below are

for specific operating conditions only.

Machine and operator sound levels will

vary at different engine and/or cooling fan

speeds. Hearing protection may be needed

when the machine is operated with a cabin

that is not properly maintained, or when

the doors and/or windows are open for

extended periods or in a noisy environment.

• The operator sound pressure level for a

standard machine confi guration, measured

according to the procedures specifi ed

in ISO 6396:2008, is 72 dB(A) with the

cooling fan speed set at maximum value.

• The machine sound power level for a

standard machine confi guration, measured

according to the procedures specifi ed in

ISO 6395:2008, is 112 dB(A) with the

cooling fan speed set at maximum value.

• The machine sound pressure level for

a standard machine confi guration,

measured according to the procedures

specified in SAE J88:2006, is 78 dB(A).

The measurement was conducted under

the following conditions: distance of 15 m

(49.2 ft), moving forward in an intermediate

gear ratio, static hydraulic cycle (with no

payload) and with the cooling fan speed

set at maximum value.

• The operator sound pressure level for

a machine installed with a Low Sound

package, measured according to the

procedures specified in ISO 6396:2008,

is 72 dB(A) with the cooling fan speed

set at maximum value.

• The machine sound power level for a

machine installed with a Low Sound

package, measured according to the

procedures specified in ISO 6396:2008,

is 109 dB(A) with the cooling fan speed

set at maximum value.

Fuel Tank –

447 L

118.1 gal

Standard

Cooling System

63 L

16.6 gal

Crankcase

37 L

9.8 gal

Transmission

66 L

17.4 gal

Differentials and

84 L

22.2 gal

Final Drives – Front

Differentials and

84 L

22.2 gal

Final Drives – Rear

Hydraulic Tank

170 L

44.9 gal

15