Vishay high power products, Half bridge" igbt mtp (ultrafast npt igbt), 80 a – C&H Technology 40MT120UHTAPbF User Manual

Page 4

Document Number: 94507

For technical questions, contact:

www.vishay.com

Revision: 01-Mar-10

3

40MT120UHAPbF, 40MT120UHTAPbF

"Half Bridge" IGBT MTP

(Ultrafast NPT IGBT), 80 A

Vishay High Power Products

Notes

(1)

T

0

, T

1

are thermistor´s temperatures

(2)

, temperature in Kelvin

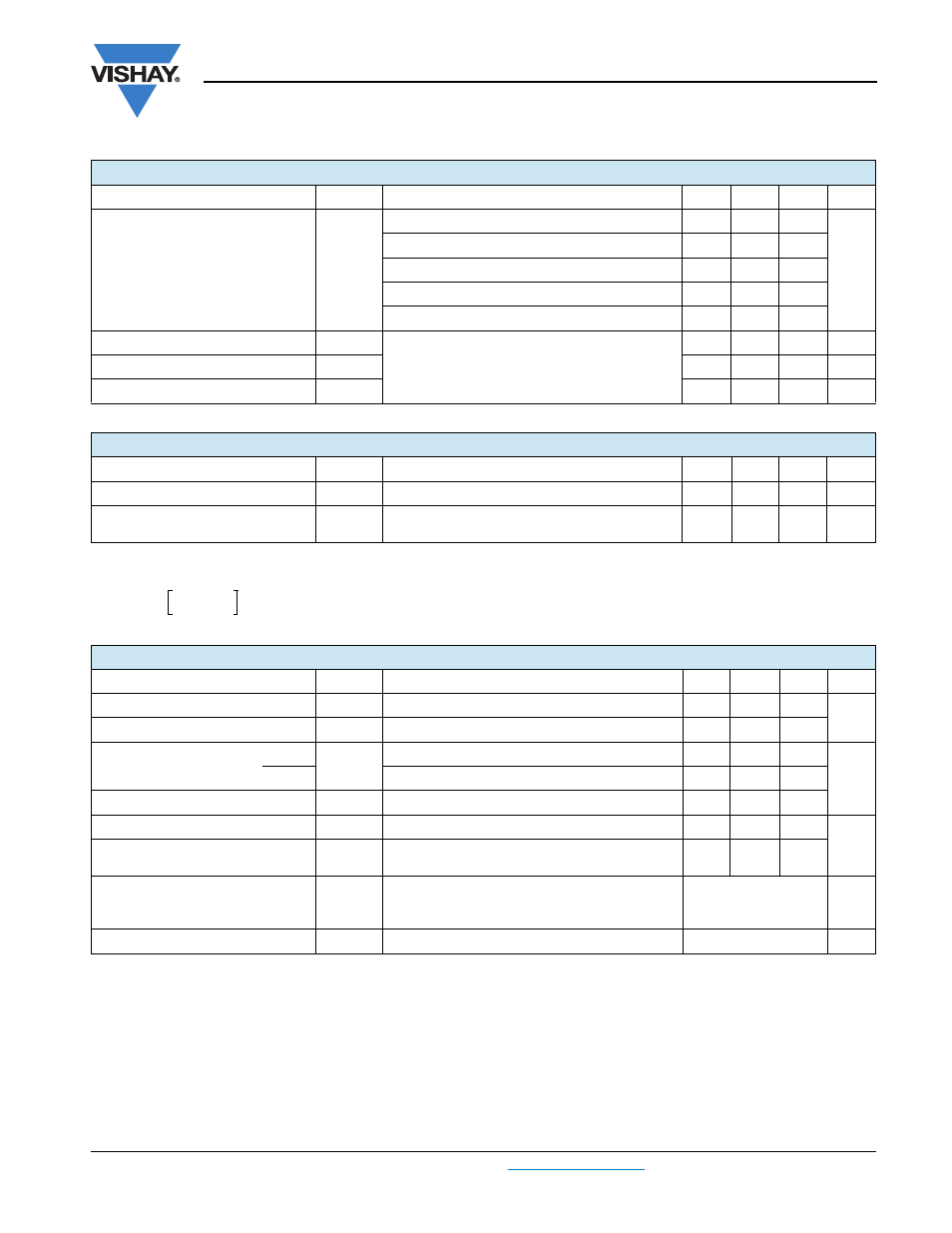

DIODE SPECIFICATIONS (T

J

= 25 °C unless otherwise specified)

PARAMETER

SYMBOL

TEST CONDITIONS

MIN.

TYP.

MAX.

UNITS

Diode forward voltage drop

V

FM

I

C

= 40 A

-

2.98

3.38

V

I

C

= 80 A

-

3.90

4.41

I

C

= 40 A, T

J

= 125 °C

-

3.08

3.39

I

C

= 80 A, T

J

= 125 °C

-

4.29

4.72

I

C

= 40 A, T

J

= 150 °C

-

3.12

3.42

Reverse recovery energy of the diode

E

rec

V

GE

= 15 V, R

g

= 5

Ω, L = 200 μH

V

CC

= 600 V, I

C

= 40 A

T

J

= 125 °C

-

574

861

μJ

Diode reverse recovery time

t

rr

-

120

180

ns

Peak reverse recovery current

I

rr

-

43

65

A

THERMISTOR SPECIFICATIONS (40MT120UHTAPbF only)

PARAMETER

SYMBOL

TEST CONDITIONS

MIN.

TYP.

MAX.

UNITS

Resistance

R

0

(1)

T

0

= 25 °C

-

30

-

k

Ω

Sensitivity index of the

thermistor material

β

(1)(2)

T

0

= 25 °C

T

1

= 85 °C

-

4000

-

K

R

0

R

1

-------

β 1

T

0

------

1

T

1

------

–

⎝

⎠

⎛

⎞

exp

=

THERMAL AND MECHANICAL SPECIFICATIONS

PARAMETER

SYMBOL

TEST CONDITIONS

MIN.

TYP.

MAX.

UNITS

Operating junction temperature range

T

J

- 40

-

150

°C

Storage temperature range

T

Stg

- 40

-

125

Junction to case

IGBT

R

thJC

-

-

0.29

°C/W

Diode

-

-

0.61

Case to sink per module

R

thCS

Heatsink compound thermal conductivity = 1 W/mK

-

0.06

-

Clearance

(1)

External shortest distance in air between 2 terminals

5.5

-

-

mm

Creepage

(2)

Shortest distance along external surface of the

insulating material between 2 terminals

8

-

-

Mounting torque to heatsink

A mounting compound is recommended and the

torque should be checked after 3 hours to allow for

the spread of the compound. Lubricated threads.

3 ± 10 %

Nm

Weight

66

g