VEGA VEGABAR 81 4 … 20 mA_HART - Operating Instructions User Manual

Page 67

67

11 Supplement

VEGABAR 81 • 4 … 20 mA/HART

45018-EN-131010

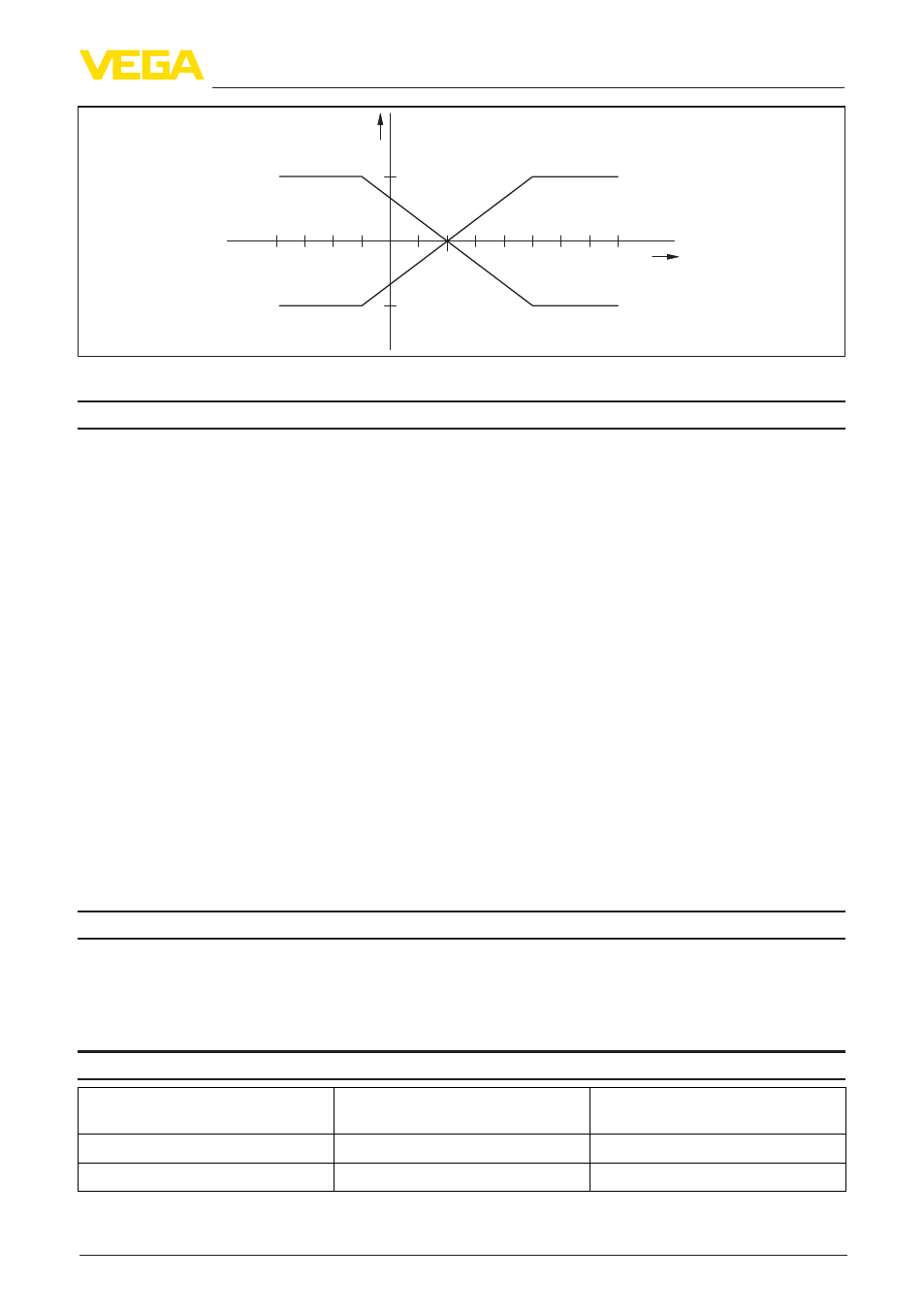

0,15 %

-0,15 %

-40°C

-20°C

20°C

40°C

60°C

80°C

Fig. 43: Thermal change, current output

Additional temperature influence through chemical seal

The specifications refer to diaphragm material 316L as well as isolating liquid silicone oil. They are

only used for estimation. The actual values depend on the diameter, material and strength of the

diaphragm as well as the isolating liquid. They are available on request.

Temperature coefficient of the chemical seal in mbar/10 K with

Ʋ Flange DN 50 PN 40, Form C,

DIN 2501

1.2 mbar/10 K

Ʋ Flange DN 80 PN 40, Form C,

DIN 2501

0.25 mbar/10 K

Ʋ Flange DN 80 PN 40, Form C,

DIN 2501 with extension 50 mm

1.34 mbar/10 K

Ʋ Flange 2" 150 lbs RF, ANSI B16.5

1.2 mbar/10 K

Ʋ Flange 3" 150 lbs RF, ANSI B16.5

0.25 mbar/10 K

Ʋ Flange 3" 150 lbs RF, ANSI B16.5 with

extension 2 "

1.34 mbar/10 K

Temperature coefficient of a cooling ele-

ment, depending on the diaphragm-ø

0.1 … 1.5 mbar/10 K

Temperature coefficient of a 1 m

long capillary line, depending on the

diaphragm-ø

0.1 … 15 mbar/10 K

Long-term stability (according to DIN 16086 and IEC 60770-1)

Applies to digital HART interface as well as to analogue current output 4 … 20 mA under refer-

ence conditions. Specifications refer to the set span. Turn down (TD) is the ratio nominal measuring

range/set span.

Long-term drift of the zero signal

3)

< (0.1 % x TD)/year

Ambient conditions

Version

Ambient temperature

Storage and transport temper-

ature

Standard version

-40 … +80 °C (-40 … +176 °F)

-60 … +80 °C (-76 … +176 °F)

Version IP 66/IP 68 (1 bar)

-20 … +80 °C (-4 … +176 °F)

-20 … +80 °C (-4 … +176 °F)

3)

Depending on which chemical seal is used, the values can also be higher.