VEGA VEGABAR 81 4 … 20 mA_HART - Operating Instructions User Manual

Page 40

40

6 Set up with the display and adjustment module

VEGABAR 81 • 4 … 20 mA/HART

45018-EN-131010

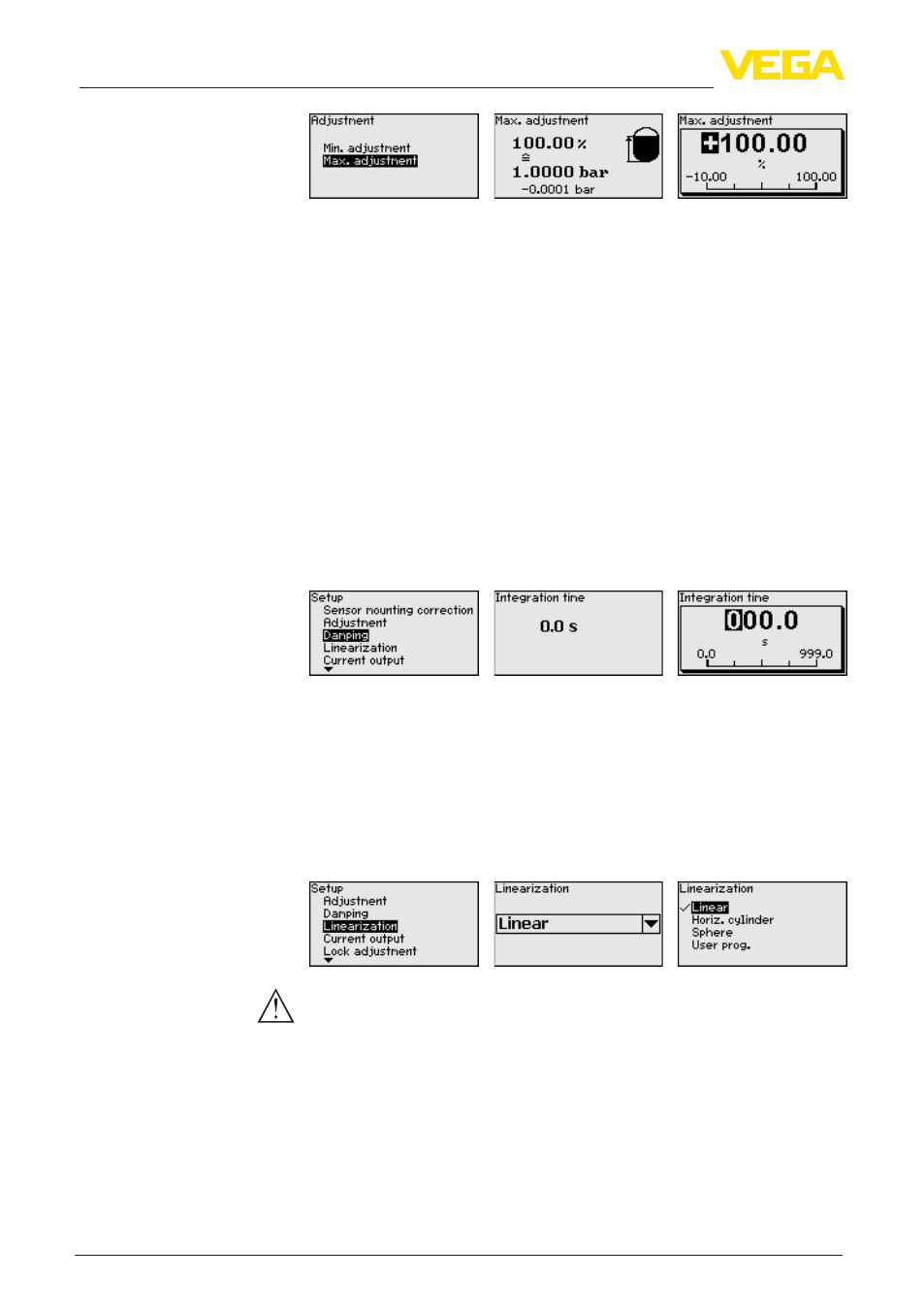

2. Edit the percentage value with [OK] and set the cursor to the

requested position with [->].

3. Set the requested percentage value (e.g. 90 %) with [+] and save

with [OK]. The cursor jumps now to the pressure value.

4. Enter the pressure value for the full vessel (e.g. 900 mbar) suit-

able for the percentage value.

5. Save settings with [OK]

The max. adjustment is finished.

For an adjustment with filling, simply enter the actual measured value

indicated at the bottom of the display.

If the adjustment ranges are exceeded, then the entered value will not

be taken over. Editing can be interrupted with [ESC] or corrected to a

value within the adjustment ranges.

To damp process-dependent measured value fluctuations, set an

integration time of 0 … 999 s in this menu item. The increment is 0.1 s.

Depending on the sensor type, the factory setting is 0.1 s.

A linearization is necessary for all vessels in which the vessel volume

does not increase linearly with the level - e.g. a horizontal cylindri-

cal or spherical tank - and the indication or output of the volume is

required. Corresponding linearization curves are preprogrammed for

these vessels. They represent the correlation between the level per-

centage and vessel volume. The linearization applies to the measured

value indication and the current output.

Caution:

Note the following, if the respective sensor is used as part of an over-

fill protection system according to WHG:

If a linearization curve is selected, the measuring signal is no longer

necessarily linear to the filling height. This must be considered by the

user especially when adjusting the switching point on the limit signal

transmitter.

In the menu items "Current output" you determine the properties of

the current output.

Setup - Damping

Setup - Linearization

Setup - Current output