VEGA VEGAFLEX 82 4 … 20 mA_HART four-wire User Manual

Page 18

18

4 Mounting

VEGAFLEX 82 • 4 … 20 mA/HART - four-wire

41830-EN-130314

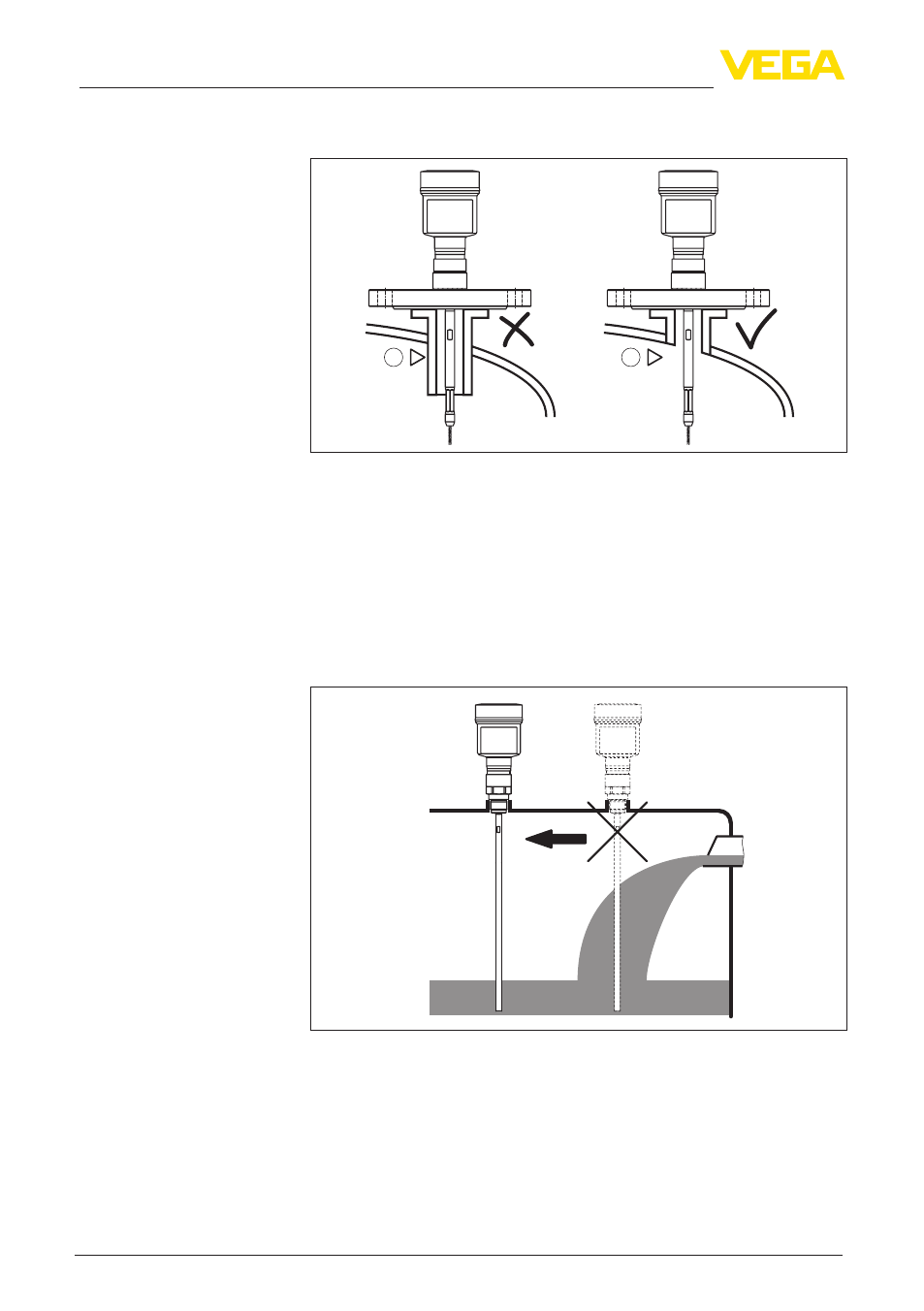

When welding the socket, make sure that the socket is flush to the

vessel top.

1

2

Fig. 9: Socket must be installed flush

1 Unfavourable installation

2 Socket flush - optimum installation

Before beginning the welding work, remove the electronics module

from the sensor. By doing this, you avoid damage to the electronics

through inductive coupling.

Do not mount the instruments in or above the filling stream. Make sure

that you detect the product surface, not the inflowing product.

Fig. 10: Mounting of the sensor with inflowing medium

The reference plane for the measuring range of the sensors is the

sealing surface of the thread or flange.

Keep in mind that a min. distance must be maintained below the refer-

ence plane and possibly also at the end of the probe - measurement

in these areas is not possible (dead band). The length of the cable

can be used all the way to the end only when measuring conductive

Welding work

Inflowing medium

Measuring range

- VEGABAR 25 (24 pages)

- VEGAFLEX 55K (32 pages)

- VEGABAR 17 (36 pages)

- D80 Hydrostatic pressure transmitters (40 pages)

- VEGAMET 513 (52 pages)

- D81 Hydrostatic pressure transmitter (44 pages)

- VEGASTAB 690 (12 pages)

- VEGASWING 83 fail safe and signal conditioning instrument VEGATOR 526 Ex (28 pages)

- VEGACONNECT 2 (4 pages)

- D81 METEC Hydrostatic pressure transmitter (44 pages)

- VEGAPULS 45 4 … 20 mA; HART compact sensor (72 pages)

- VEGAMET 515 (68 pages)

- VEGAFLEX 52K (32 pages)

- Capacitive electrodes EK Profibus PA (56 pages)

- VEGATOR 631 S1 (4 pages)

- VEGAPULS 63 (≥ 2.0.0 - ≤ 3.8) 4 … 20 mA_HART - two-wire (68 pages)

- Capacitive electrodes EK 4 … 20 mA - Compact (40 pages)

- VEGABAR 65 4 … 20 mA_HART (76 pages)

- VEGABAR 64 Profibus PA (80 pages)

- VEGABAR 44 4 … 20 mA (28 pages)

- VEGADIS 50 Ex (8 pages)

- VEGAPULS 51V…54V (96 pages)

- VEGAFLEX 54P (Profibus PA) (48 pages)

- VEGASEL 643 (16 pages)

- VEGAPULS 56K (68 pages)

- VEGAFLEX 54K (36 pages)

- VEGABAR 41 HART (44 pages)

- VEGATOR 537 Ex (16 pages)

- VEGACAP 82-98 (36 pages)

- VEGADIS 371 Ex (20 pages)

- Capacitive electrodes EL Profibus PA (56 pages)

- VEGAFLEX 52V (36 pages)

- VEGAFLEX 51K (32 pages)

- VEGALOG 571 EP (Ex) (32 pages)

- D84 Hydrostatic pressure transmitter (44 pages)

- VEGABAR 64 Foundation Fieldbus (80 pages)

- VEGABAR 61 4 … 20 mA_HART (80 pages)

- VEGASCAN 850 (92 pages)

- VEGASON 54P…56P Profibus PA (68 pages)

- D77 Hydrostatic pressure transmitters (24 pages)

- VEGATRENN 546 Safety barrier type 146 (8 pages)

- VEGASON 71 - 1 … 75 - 1 (52 pages)

- VEGABAR 40 HART (40 pages)

- Capacitive electrodes EL … (44 pages)

- VEGABAR 24 (28 pages)