VEGA VEGAFLEX 86 Modbus and Levelmaster protocol User Manual

Page 23

23

4 Mounting

VEGAFLEX 86 • Modbus and Levelmaster protocol

41848-EN-130314

You can find further information in the supplementary instructions of

the rod extension.

Vapours, superimposed gases, high pressures and temperature dif-

ferences can change the spreading speed of radar impulses.

There are two possibilities to correct these deviations.

Corrective value in the process control system

In the technical data under "Influence of superimposed gas and pres-

sure on accuracy" you can find a table with deviation values in some

typical gases or in steam.

In the control system (DCS) you can correct the measurement results

of the VEGAFLEX 86 with these values.

The prerequisite is constant temperature and pressure in the vessel.

Automatic correction via the reference distance

The VEGAFLEX 86 can be equipped optionally with a running time

correction via reference distance. The probe can carry out an auto-

matic running time correction with it.

The reference point must hence not be overfilled. The upper dead

band is hence 450 mm (17.7 in).

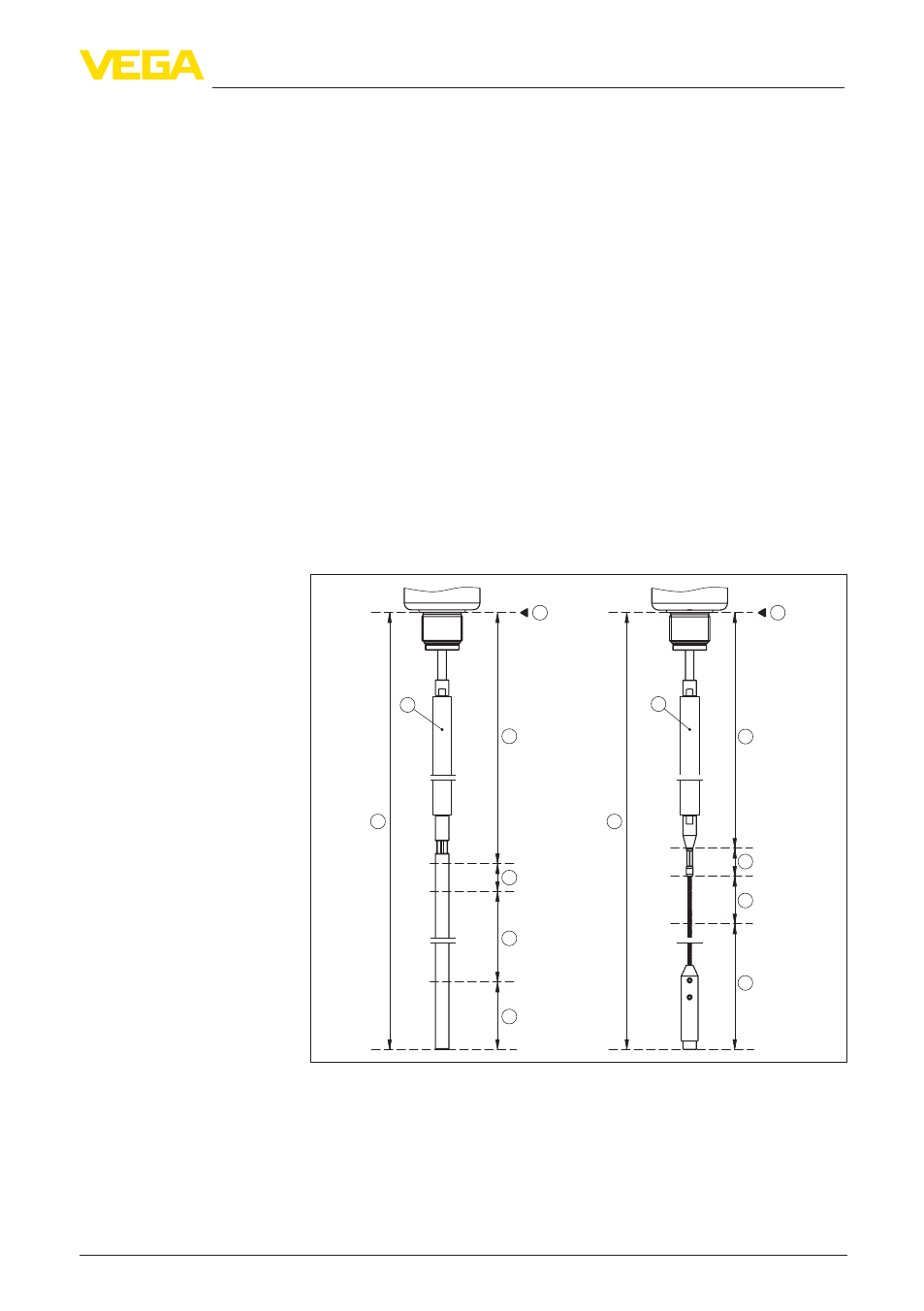

2

6

3

4

5

1

2

6

5

4

3

1

7

7

Fig. 15: Measuring ranges - VEGAFLEX 86 with steam compensation

1 Reference plane

2 Probe length L

3 Measuring range

4 Upper dead band

5 Lower dead band

6 Additional upper dead band by steam compensation

7 Reference measurement distance to steam compensation

Steam boiler applications