VEGA VEGAFLEX 86 Modbus and Levelmaster protocol User Manual

Page 20

20

4 Mounting

VEGAFLEX 86 • Modbus and Levelmaster protocol

41848-EN-130314

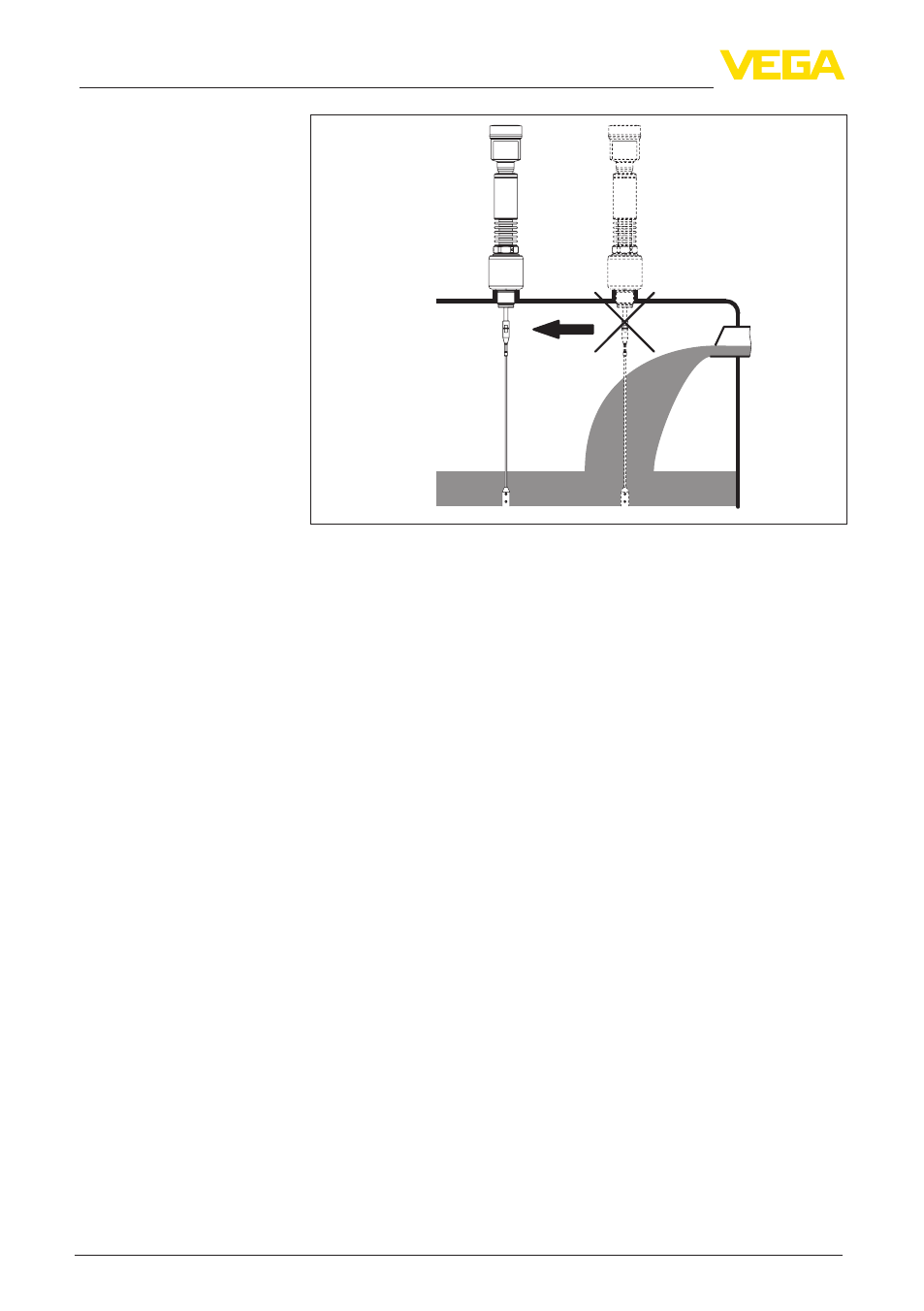

Fig. 12: Mounting of the sensor with inflowing medium

The reference plane for the measuring range of the sensors is the

sealing surface of the thread or flange.

Keep in mind that a min. distance must be maintained below the refer-

ence plane and possibly also at the end of the probe - measurement

in these areas is not possible (dead band). The length of the cable

can be used all the way to the end only when measuring conductive

products. These blocking distances for different mediums are listed

in chapter "Technical data". Keep in mind for the adjustment that the

default setting for the measuring range refers to water.

The process fitting must be sealed if there is gauge or low pressure in

the vessel. Before use, check if the seal material is resistant against

the measured product and the process temperature.

The max. permissible pressure is specified in chapter "Technical

data" or on the type label of the sensor.

Standpipes or bypass tubes are normally metal tubes with a diameter

of 30 … 200 mm (1.18 … 7.87 in). In measurement technology such a

tube corresponds to a coax probe. It does not matter if the standpipe

is perforated or slotted for better mixing. Lateral inlets with bypass

tubes also do not influence the measurement.

Measuring probes can be mounted in bypass tubes up to DN 200.

Microwaves can penetrate many plastics. For process technical rea-

sons, plastic standpipes are problematic. If durability is no problem,

then we recommend the use of metal standpipes.

When the VEGAFLEX 86 is used in standpipes or bypass tubes,

contact with the tube wall must be avoided. We recommend for this

purpose a cable probe with centering weight.

Measuring range

Pressure

Standpipes or bypass

tubes