VEGA VEGAFLEX 81 HART - integrated accumulator User Manual

Page 12

12

3 Product description

VEGAFLEX 81 • HART - integrated accumulator

44640-EN-130430

Probe end tracking

To increase sensitivity, the probe is equipped with probe end tracking.

In products with a low dielectric constant, this function is very helpful.

This is the case, for example, in plastic granules, packing chips or in

vessels with fluidized products.

Between a dielectric constant of 1.5 and 3, the function switches on, if

required. As soon as the level echo can no longer be detected, probe

end tracking is automatically activated. The measurement is contin-

ued with the last calculated dielectric constant.

The accuracy thus depends on the stability of the dielectric constant.

If you measure a medium with a dielectric constant below 1.5, probe

end tracking is always active. In this case, you have to enter the

dielectric constant of the medium. A stable dielectric constant is very

important here.

High frequency microwave impulses are guided along a steel cable or

rod. Upon reaching the product surface, a part of the microwave im-

pulses is reflected. The other part passes through the upper product

and is reflected by the interface. The running times to the two product

layers are processed by the instrument.

TS

d1

h1

h2

d2

1

L2

L1

L3

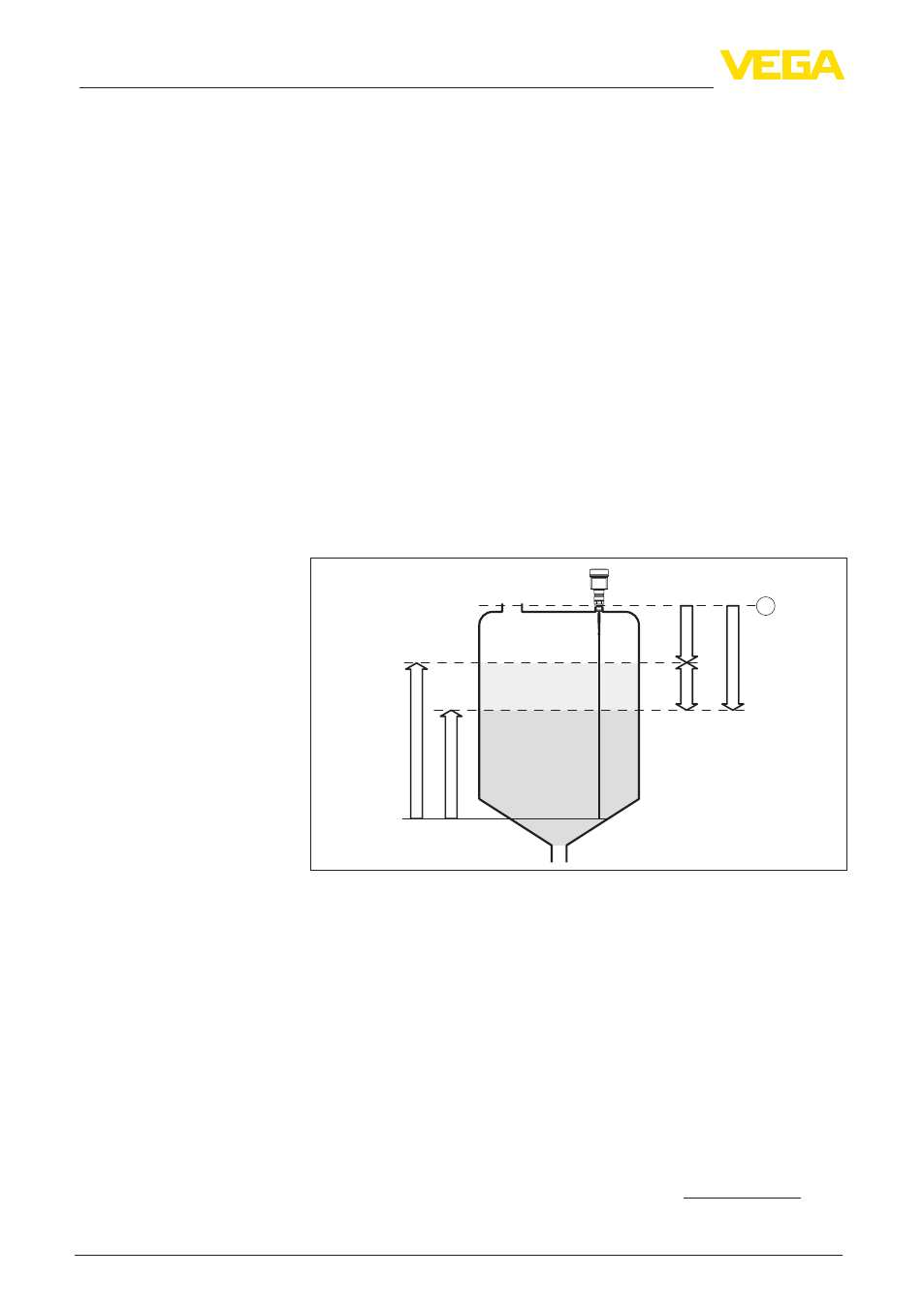

Fig. 6: Interface measurement

1 Sensor reference plane (seal surface of the process fitting)

d1 Distance to the interface (HART value 1)

d2 Distance to the level (HART value 3)

TS Thickness of the upper medium (d1 - d2)

h1 Height - Interface

h2 Height - Level

L1 Lower medium

L2 Upper medium

L3 Gas phase

Upper medium (L2)

•

The upper medium must not be conductive

•

The dielectric constant of the upper medium must be known (input

required). Min. dielectric constant: rod version 1.6. You can find a

list of dielectric constants on our home page: www.vega.com

Functional principle - in-

terface measurement

Prerequisites for inter-

face measurement