VEGA VEGADIF 65 4 … 20 mA_HART User Manual

Page 82

82

11 Supplement

VEGADIF 65 • 4 … 20 mA/HART

36128-EN-130417

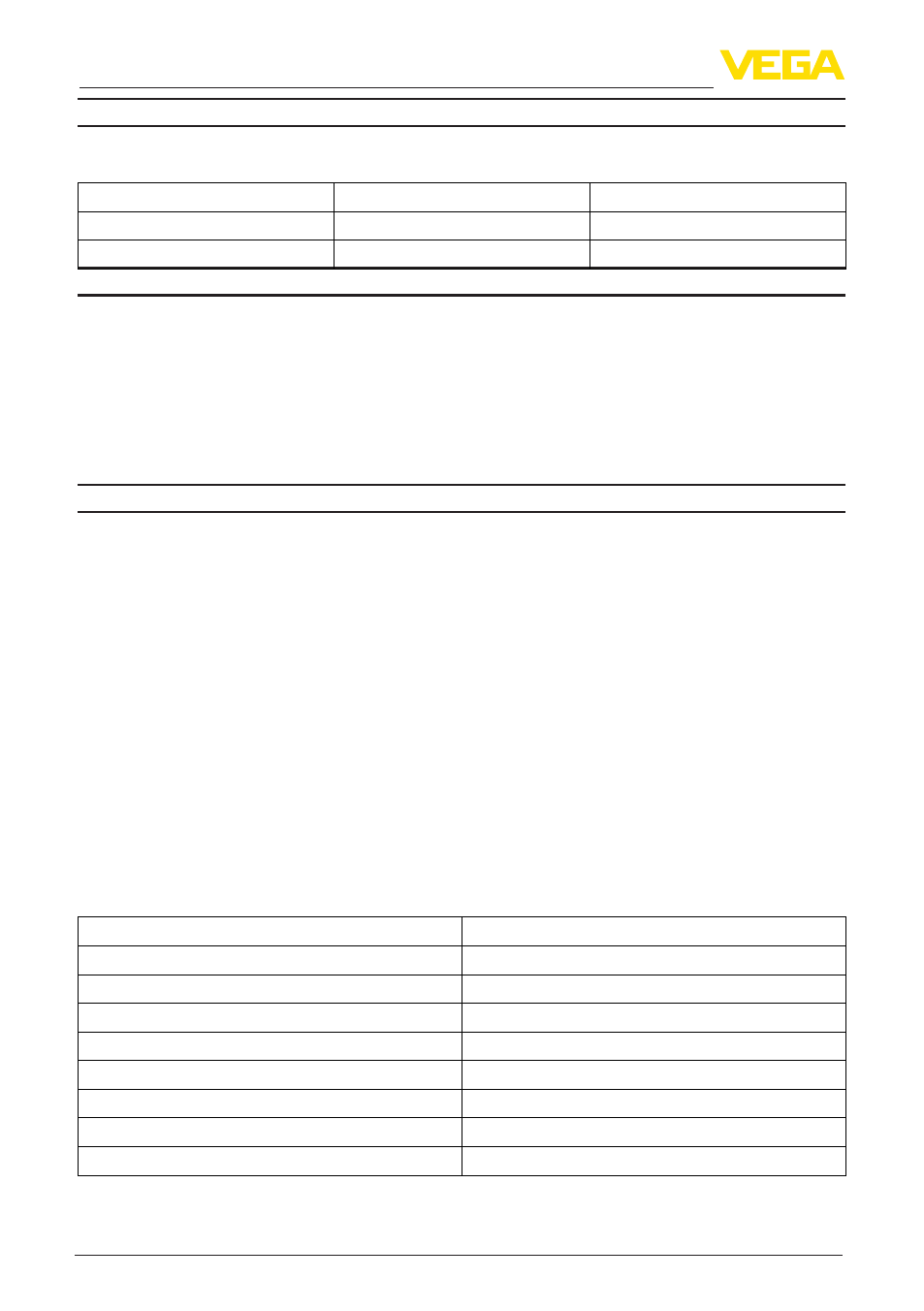

Long-term stability (according to DIN 16086 and IEC 60770-1)

Applies to digital interfaces (HART, Profibus PA, Foundation Fieldbus) as well as to analogue cur-

rent output 4 … 20 mA. Specifications refer to the measuring range final value.

Measuring ranges

1 year

5 years

10 mbar, 100 mbar

±0.18 %

-

500 mbar, 3 bar, 16 bar

±0.05 %

±0.125 %

Ambient conditions

Ambient, storage and transport temperature

Ʋ Standard version

-40 … +80 °C (-40 … +176 °F)

Ʋ Version for oxygen applications

18)

-40 … +60 °C (-40 … +140 °F)

Ʋ Versions IP 66/IP 68 (1 bar) connec-

tion cable PE

-20 … +60 °C (-4 … +140 °F)

Ʋ Versions IP 66/IP 68 (1 bar) and IP 68,

connection cable PUR

-20 … +80 °C (-4 … +176 °F)

Process conditions

The pressure and temperature specifications are used as overview. In general, the max. pressure

for the pressure transmitter depends on the weakest (with regard to pressure) link. In detail, the

respective specifications of the type label apply.

Process temperature limits

Specifications apply to the basic version as well as to the minus side with version with single

chemical seal

19)

Ʋ With measuring cells PN 420

Lower temperature limit -10 °C (+14 °F).

Ʋ With effective pressure lines longer

than 100 mm

-40 … +120 °C (-40 … +248 °F)

Ʋ With effective pressure lines longer

than 100 mm, process fitting steel

C22.8

-40 … +120 °C (-40 … +248 °F)

Specifications apply to suitable chemical seals

Ʋ Chemical seal CSS plus side, CSB

both sides

-40 … +400 °C (-40 … +752 °F)

Process temperature limits according to the seal material

Seal material

Temperature limits

FKM

-20 … +85 °C (-4 … +185 °F)

FFKM (Kalrez 6375)

-5 … +85 °C (23 … +185 °F)

EPDM

-40 … +85 °C (-40 … +185 °F)

PTFE

-40 … +85 °C (-40 … +185 °F)

NBR

-20 … +85 °C (-4 … +185 °F)

Copper

-40 … +85 °C (-40 … +185 °F)

Copper, for oxygen application

-20 … +60 °C (-4 … +140 °F)

FKM, cleaned

-10 … +85 °C (+14 … +185 °F)

18)

Up to 60 °C (140 °F).

19)

For the version for oxygen application, note chapter "Oxygen applications".