4 pump control 1/2 (running time controlled) – VEGA VEGAMET 625 User Manual

Page 43

43

8 Application examples

VEGAMET 625 • Double channel HART

28970-EN-130701

instructions manual of VEGAFLEX. For this application, do not

enter a dielectric figure directly on VEGAFLEX, because this

value will be overwritten automatically by VEGAMET 625

•

Adjustment

– Each VEGAFLEX is shipped with default settings. The values of

this adjustment are automatically tranferred to VEGAMET 625

during the setup of the interface measurement. Hence, manual

adjustment is usually not necessary. Should the instrument

require a special adjustment, this adjustment can be carried

out any time under "Measurement loops - Adjustment". Keep in

mind that this adjustment must then be carried out separately

for all three measurement loops.

TS

d1

h1

h2

d2

1

L2

L1

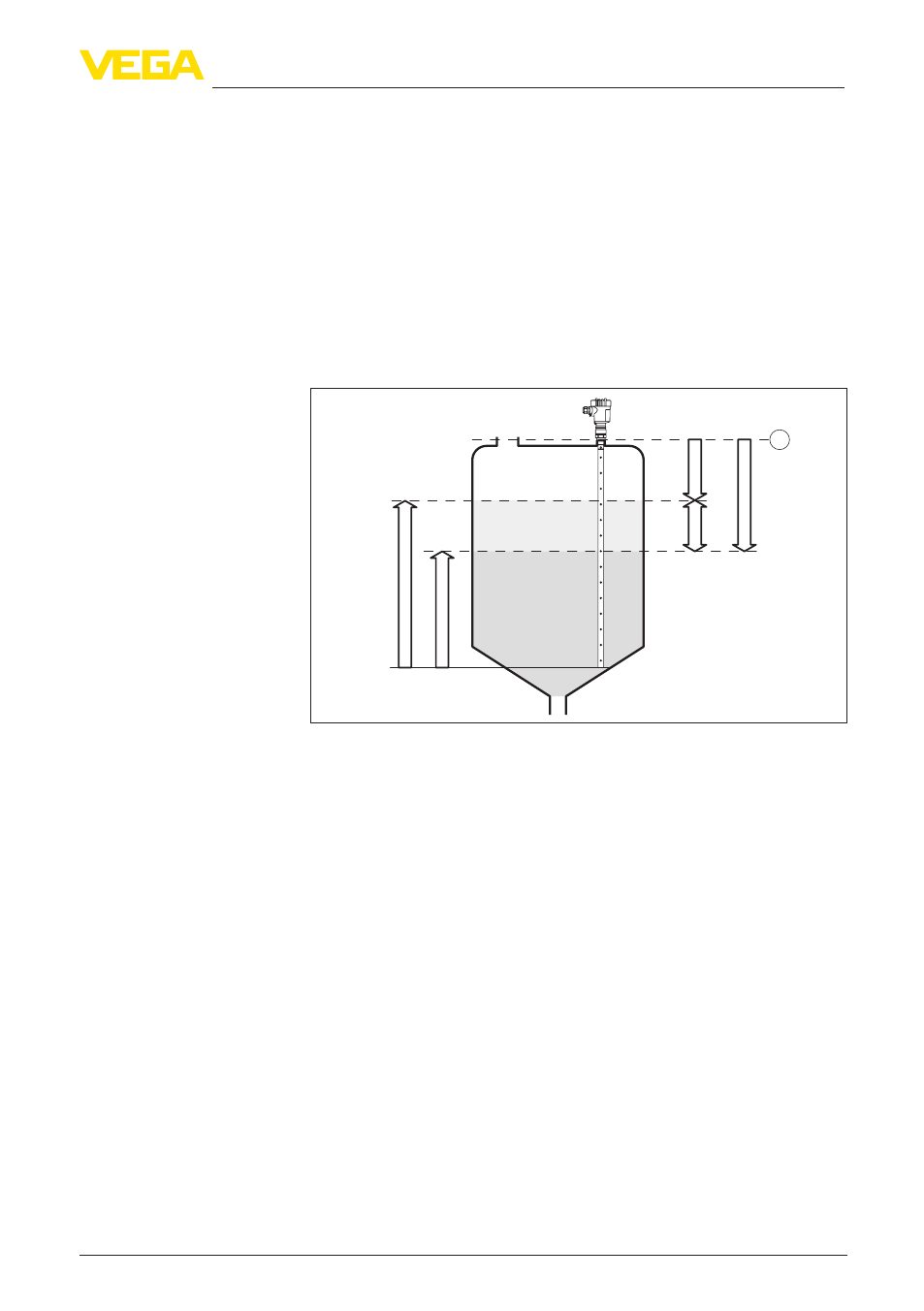

Fig. 13: Interface measurement

1 Reference plane

d1 Distance to the interface, meas. loop 1

d2 Distance to the level, meas. loop 2

TS Thickness of the upper medium (d1-d2), meas. loop 3 (displayed value)

h1 Height - Interface (displayed value)

h2 Height - Level (displayed value)

L1 Lower medium

L2 Upper medium

8.4 Pump control 1/2 (running time controlled)

Pump control 1/2 is used to control several pumps with the same

function dependent on the previous running time. Always the pump

with the shortest running time is switched on and the pump with

the longest running time switched off. With increased requirement,

all pumps can also run at the same time dependent on the entered

switching points. With this measure, a steady utilization of the pumps

is achieved and the reliability increased.

All relays with activated pump control are not assigned to a certain

switching point but are switched on or off depending on the accu-

mulated operating time. The signal conditioning instrument selects

the relay with the shortest operating time when the switch-on point

Functional principle