Wiha dead-blow hammer – Wiha Tools Product Catalogue 2012-2014 User Manual

Page 146

291

www.wiha.com

290

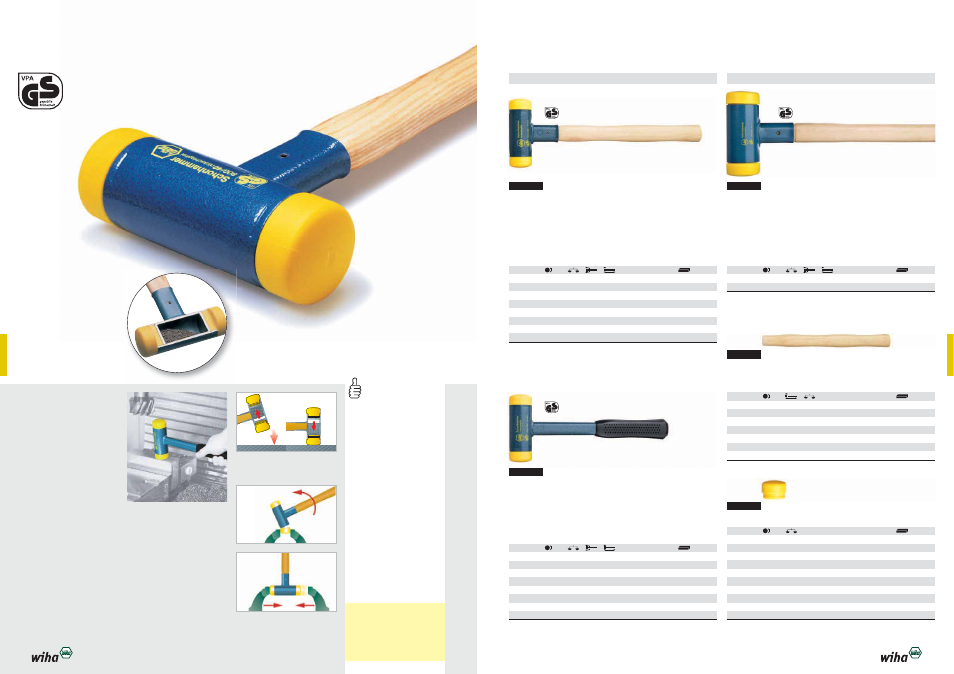

Wiha dead-blow hammer.

A star in the world of recoilless tools.

The face is made of medium-hard

polyurethane for full blows and protects

delicate surfaces and edges.

The special metal filling in the hammer

casing enables recoilless working.

Wiha has now put an end to the

familiar problems associated with

the stress on joints and muscles

when working with recoiling

hammers. The Wiha dead-blow

hammer has a special filling in the

hammer casing to prevent recoil.

Professionals who use these

hammers on a continuous basis, for

example, in tool and die shops or in

body maintenance and sheet-metal

work, appreciate the benefits of this

recoilless hammer from Wiha.

Wiha dead-blow hammer.

•

Recoilless working due to

special metal filling in the

hammer casing

•

The hammer weight is

increased by about 25%

for additional power

•

Easy on delicate surfaces and

edges as a result of its comfort

cushing surface

•

Available with hickory wood

handle or steel tube shaft

•

Faces and wooden handles

available as spare parts

Hammers.

800

Dead-blow hammer with hickory handle.

Faces: Both yellow: Medium hard, colourfast and wear-resistant polyurethane.

Housing: Manufactured from precision steel tubing with welded on shaft,

powder coated.

Shaft: Hickory handle coated with ergonomic profile and high quality surface.

Standards: GS-mark: Tested safety.

Application: Controlled strikes e.g. on workpieces being held by vices or

assembly work.

Extra: With cast iron balls inside the hammer head for recoilless work.

Order-No.

02092 25

320

108

320

5

02093

30

460

115

350

5

02094 35

580

118

355

5

02095

40

760

125

375

5

02096 45

1000

130

380

2

02097

50

1250

135

385

2

02098 60

2000

165

420

2

02099

70

2600

165

430

2

802

Dead-blow hammer with steel tube shaft.

Faces: Both yellow: Medium hard, colourfast and wear-resistant polyurethane.

Housing: Manufactured from precision steel tubing, powder coated.

Shaft: Welded, powder coated steel tube with ergonomic rubber handle.

Standards: GS-mark: Tested safety.

Application: Controlled strikes e.g. on workpieces being held by vices or

assembly work.

Extra: With cast iron balls inside the hammer head for recoilless work.

Order-No.

02122 25

520

108

288

5

02123

30

600

115

290

5

02124 35

700

118

300

5

02125

40

850

125

305

5

02126 45

1060

130

310

2

02127

50

1400

135

365

2

02128 60

2050

165

375

2

02129

70

2750

165

385

2

Sledgehammers. Spare parts.

800

Dead-blow sledge hammer with hickory handle.

Faces: Both yellow: Medium hard, colourfast and wear-resistant polyurethane.

Housing: Manufactured from precision steel tubing with welded on shaft,

powder coated.

Shaft: Hickory handle coated with ergonomic profile and high quality surface.

Standards: GS-mark: Tested safety.

Application: Controlled positioning strikes in assembly and disassembly,

straightening.

Extra: With cast iron balls inside the hammer head for recoilless work.

Order-No.

02101 80

4550

205

880

1

02091

100

6860

210

1000

1

800S

Hickory handle for dead-blow hammer.

Material: Carefully selected hickory with high quality surface.

Properties: Over the years, hickory, an extremely hard wood,

has proven to be the best material for hammer handles.

Order-No.

02113 25

295

69

10

02114

30/35

320

113

10

02115 40/45

335

123

10

02116

50

335

133

10

02117 60/70

360

165

5

28051

80

800

550

VPA GS-mark

1

28052 100

900

860

VPA GS-mark

1

800K

Hammer face, yellow for dead-blow hammer.

Material: Medium hard polyurethane, colourfast and wear-resistant.

Order-No.

02103 25

16

10

02104

30

22

10

02105 35

30

10

02106

40

45

10

02107 45

63

5

02108

50

86

5

02109 60

130

5

02110

70

178

5

02111 80

250

2

02102

100

449

2

Simple exchange of

worn hammer faces:

1. Grip the hammer in the vice,

lift to remove old hammer face.

2.Press the new hammer face

into the handle until it locks

into position.

Wear safety glasses and protective

gloves when working with soft head

hammers.

In addition, observe the national

standards and regulations.