Veris Technologies 2000XA Soil EC Mapping System (1997-2008 floppy disk drive 1.76G) - Operating Instructions User Manual

Page 10

Veris Technologies

Pub. #OM 1CM02-1

10

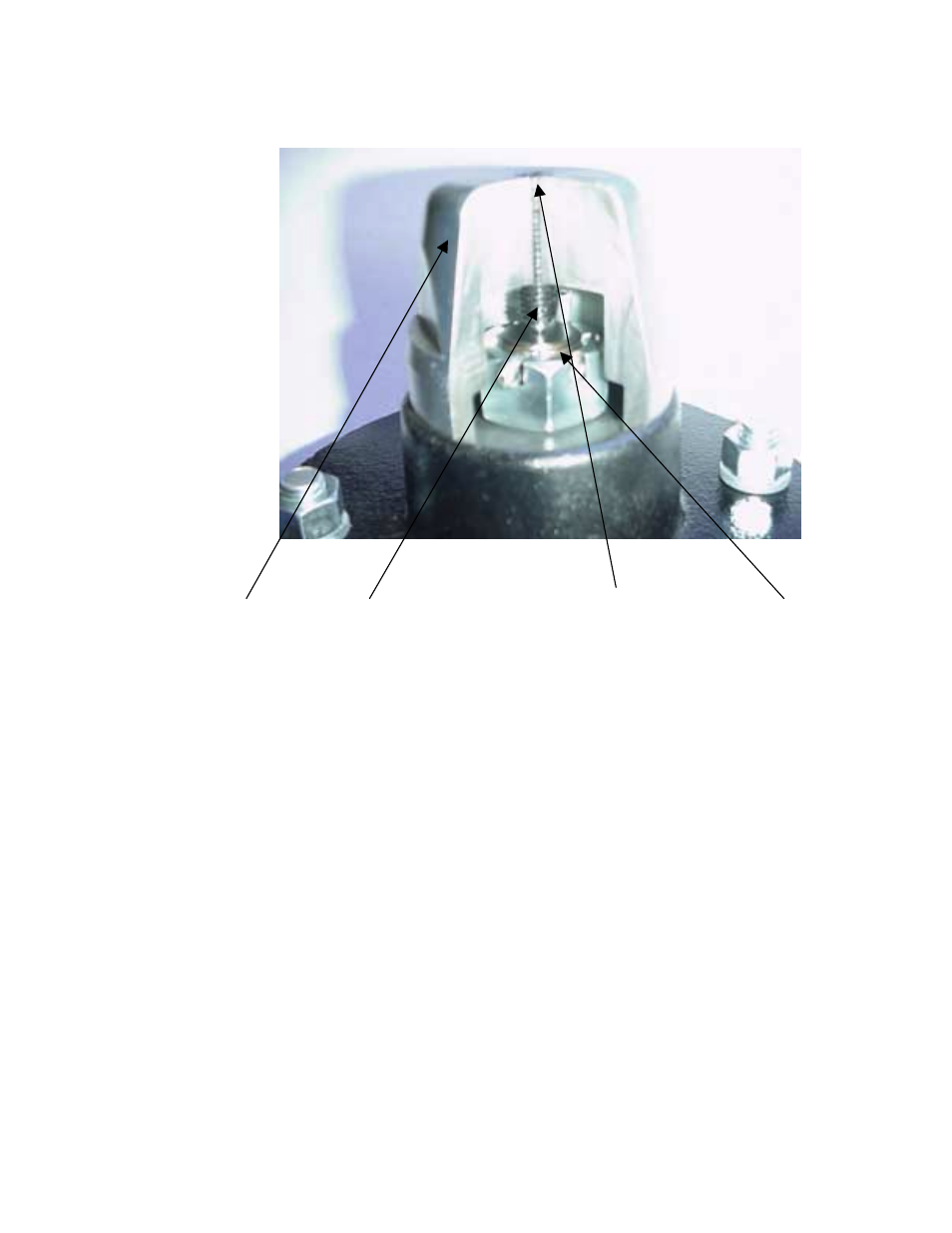

Here is a cut away view of the hubcap assembly

Cap

Commutator

Set screw

Spindle

Note: If you are still unable to obtain favorable resistance readings, check for

excessive corrosion at the coulter blade mounting bolts, or the terminal located

near the coulter pivot.

ANNUAL MAINTENACE

Wheel hubs --

On and annual basis, disassemble, clean, and properly repack the wheel

hubs with suitable wheel bearing grease. It is advisable to replace the seals.

As with any tapered roller bearing, proper pre-load will extend the

life of the assembly. Fully tighten the nut, then rotate backward up to ¼

turn, so that the hub turns freely, without endplay. Install cotter pin, and

reinstall hub cap.

Coulter electrode

hubs --

The coulter electrode hubs operate in a significantly harsh environment,

and annual inspection is of utmost importance. The double-lip seals are

designed to keep grease in, and contaminates out, but they are the cause of

practically all hub failures. It is advisable to disassemble, clean, repack, and

re-install annually. To perform this maintenance, do the following:

1) Remove hub cap by turning in a clockwise direction (left-hand thread

prevents loosening in operation).

2) Remove cotter pin, castle nut, thrust washer, and remove hub.

3) Remove outer bearing and knock out inner bearing using a wooden

dowel or brass rod. Be sure to match each bearing to its location on the