Spicer Wheel Ends Service Manual, Steer & Drive Wheel Ends User Manual

Page 54

52

Appendix

Appendix

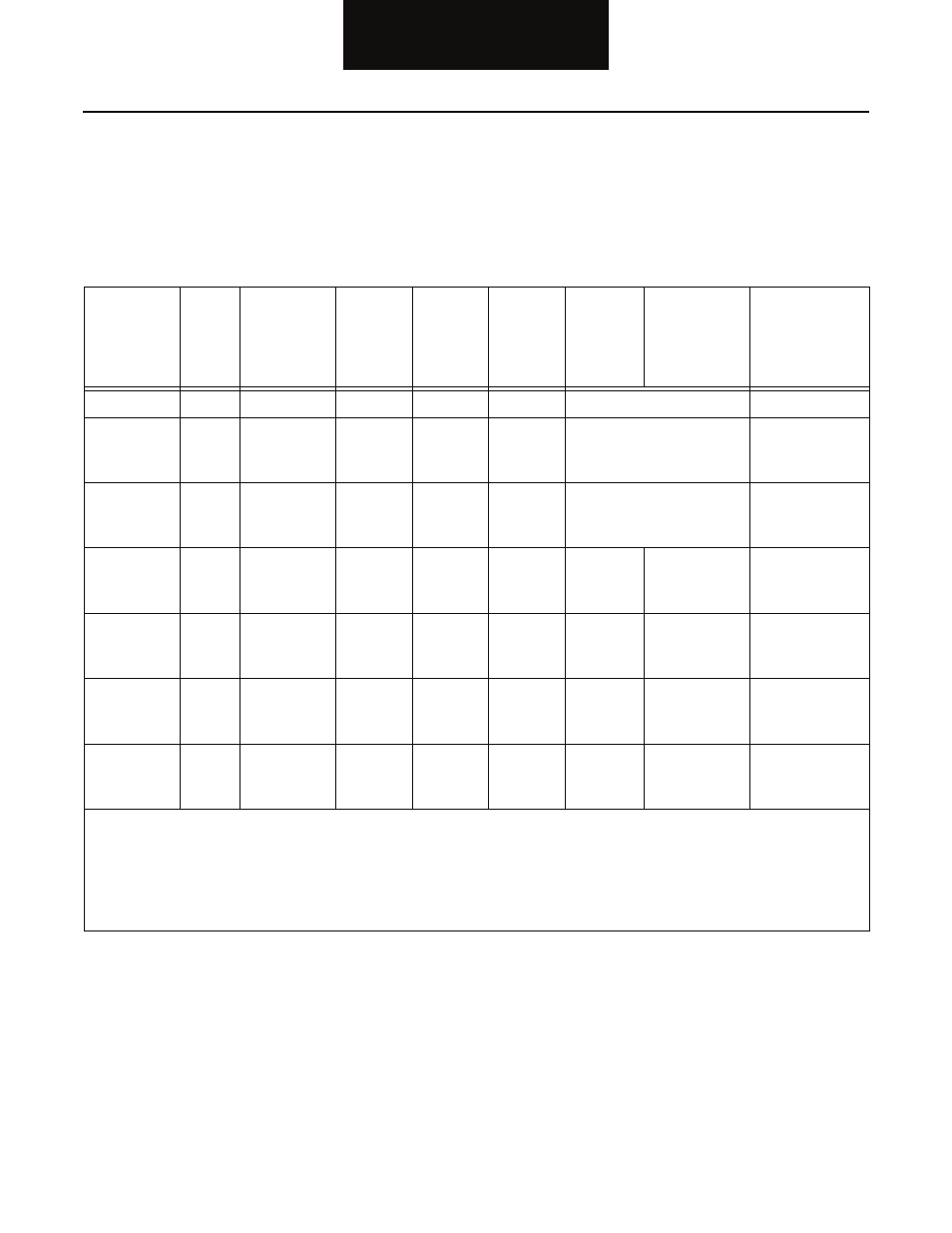

Wheel Bearing Adjustment Procedure for Standard Hubs (Not Including Pro-Torque)

STEP 1: Lubricate the wheel bearing with clean axle lubricant of the same type used in the axle sump or hub assembly.

Note: Never use an impact wrench when tightening or loosening lug nuts or bolts during the procedure.

INITIAL

ADJUSTING

NUT

TORQUE

ft.lbs. (N•m)

INITIAL

BACK

OFF

FINAL

ADJUSTING

NUT

TORQUE

ft.lbs. (N•m)

BACK OFF

AXLE

TYPE

BACK OFF

THREADS

PER INCH

BACK OFF

FINAL

BACK OFF

JAM NUT

TORQUE

NUT SIZE

in. (mm)

JAM NUT

TORQUE

TORQ. SPECS.

ft.lbs. (N•m)

ACCEPTABLE

END-PLAY

in. (mm)

STEP 2

STEP 3

STEP 4

STEP 5

STEP 6

STEP 7

STEP 8

200 (271)

while rotating

wheel

One

Full

Turn

50 (68 )

while rotating

wheels

Steer

(Front)

Non-Drive

12

1/6 Turn *

Install Cotter Pin to lock

Axle Nut in position

0.001-0.005

(0.025-0.127)

***

200 (271)

while rotating

wheel

One

Full

Turn

50 (68 )

while rotating

wheels

Steer

(Front)

Non-Drive

18

1/4 Turn *

Install Cotter Pin to lock

Axle Nut in position

0.001-0.005

(0.025-0.127)

***

200 (271)

while rotating

wheel

One

Full

Turn

50 (68 )

while rotating

wheels

Steer

(Front)

Non-Drive

14

1/2 Turn

Less than

2-5/8

(66.7)

200-300

(271-407)

0.001-0.005

(0.025-0.127)

***

200 (271)

while rotating

wheel

One

Full

Turn

50 (68 )

while rotating

wheels

Steer

(Front)

Non-Drive

18

1/2 Turn

Less than

2-5/8

(66.7)

200-300

(271-407)

0.001-0.005

(0.025-0.127)

***

200 (271)

while rotating

wheel

One

Full

Turn

50 (68 )

while rotating

wheels

Drive

12

1/4 Turn

Dowel

Type

Washer

200-300

(271-407)

0.001-0.005

(0.025-0.127)

***

200 (271)

while rotating

wheel

One

Full

Turn

50 (68 )

while rotating

wheels

Drive

16

1/4 Turn

Tang Type

Washer

**

200-300

(271-407)

0.001-0.005

(0.025-0.127)

***

* If dowel pin and washer (or washer tang and nut flat) are not aligned, remove the washer, turn it over, and reinstall.

If required, loosen the inner (adjusting) nut just enough for alignment.

** Bendable type washer lock only: Secure nuts by bending one wheel nut washer tang over the inner and outer nut. Bend the

tangs over the closest flat perpendicular to the tang.

*** As measured per procedure with Dial Indicator.