Remove differential carrier, Install differential carrier – Spicer Convertible Tandem Axles User Manual

Page 16

10

Carrier Assembly

Remove Differential Carrier

Note: The removal of the forward carrier does not require dis-

connecting of the inter-axle driveline and removal of the

output shaft yoke assembly as most other Spicer tan-

dems require.

Standard Differentials

1. Block the vehicle.

2. Drain axle lubricant.

3. Disconnect driveline.

4. Disconnect lead wires to the selector switch and air

line at shift cylinder.

5. Remove axle shafts.

WARNING:

Do not lie under carrier after fasteners are removed. Use

transmission jack to support differential carrier assembly

prior to loosening fasteners.

6. To remove axle shaft, remove axle stud nuts.

(If used, remove lock washers and taper dowels.)

7. Remove axle shafts.

Note: All models in this publication use axle shafts with

unequal lengths. Axle shafts may also be location spe-

cific with various wheel equipment. Do not misplace axle

shafts from their intended location. Identify left and right

shafts for reference during reassembly.

TIP: If necessary, loosen dowels by holding a brass

drift in the center of the shaft head and striking drift

with a sharp blow with a hammer.

CAUTION:

Do not strike the shaft head with a steel hammer. Do not use

chisels or wedges to loosen shaft or dowels.

8. Remove carrier cap screws, nuts, and lock washers.

9. Remove differential carrier assembly.

Install Differential Carrier

Before installing carrier assembly, inspect and thoroughly

clean interior of axle housing using an appropriate solvent

and clean rag.

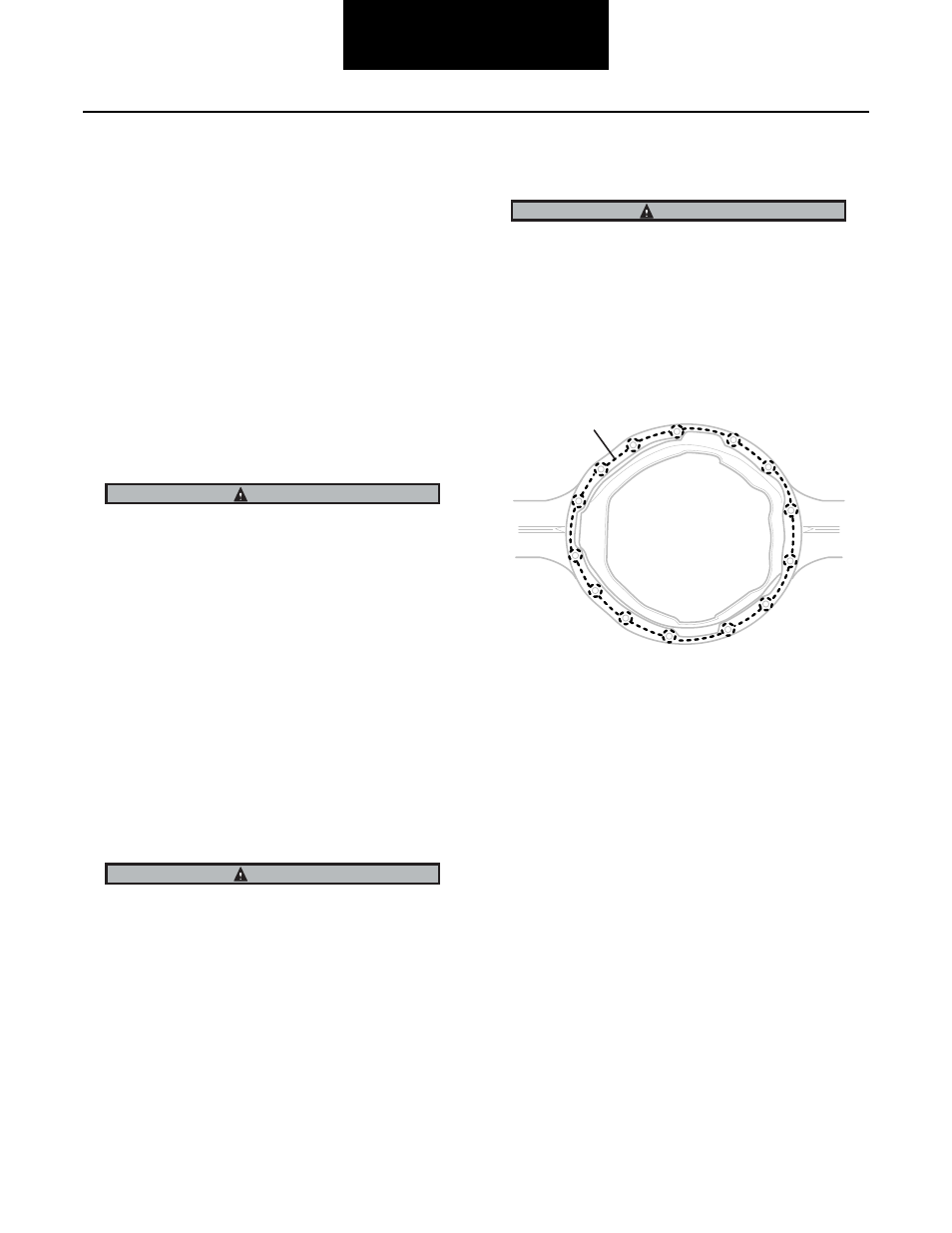

1. Apply Spicer approved RTV compound on axle

housing mating surface as shown in the illustration.

Completely remove all old gasket material prior to

applying new material. Compound will set in 5 min-

utes. Install carrier before compound sets or reapply.

TIP: To assist in installing complete differential car-

rier use two pieces of threaded rod (M16 X 1.5)

threaded into carrier cap screw holes. Rod should be

approximately 6" long. Use these to pilot the carrier

into the housing.

2. Install carrier to housing, lock washers, cap screws

and nuts. Torque to proper specification. Torque to

250–290 lb-ft. (339–393 N•m).

3. Install axle shafts and axle stud nuts. (If used, also

install lock washers and tapered dowels.)

4. Add axle lubricant. Fill to bottom of filler hole.

5. Connect driveline, making sure all yokes are in

phase. Lubricate u-joints.

WARNING

CAUTION

IMPORTANT

1 - Apply silicone gasket in this pattern

1