Inspect components – Spicer Convertible Tandem Axles User Manual

Page 13

7

Inspec

tio

n

Inspection

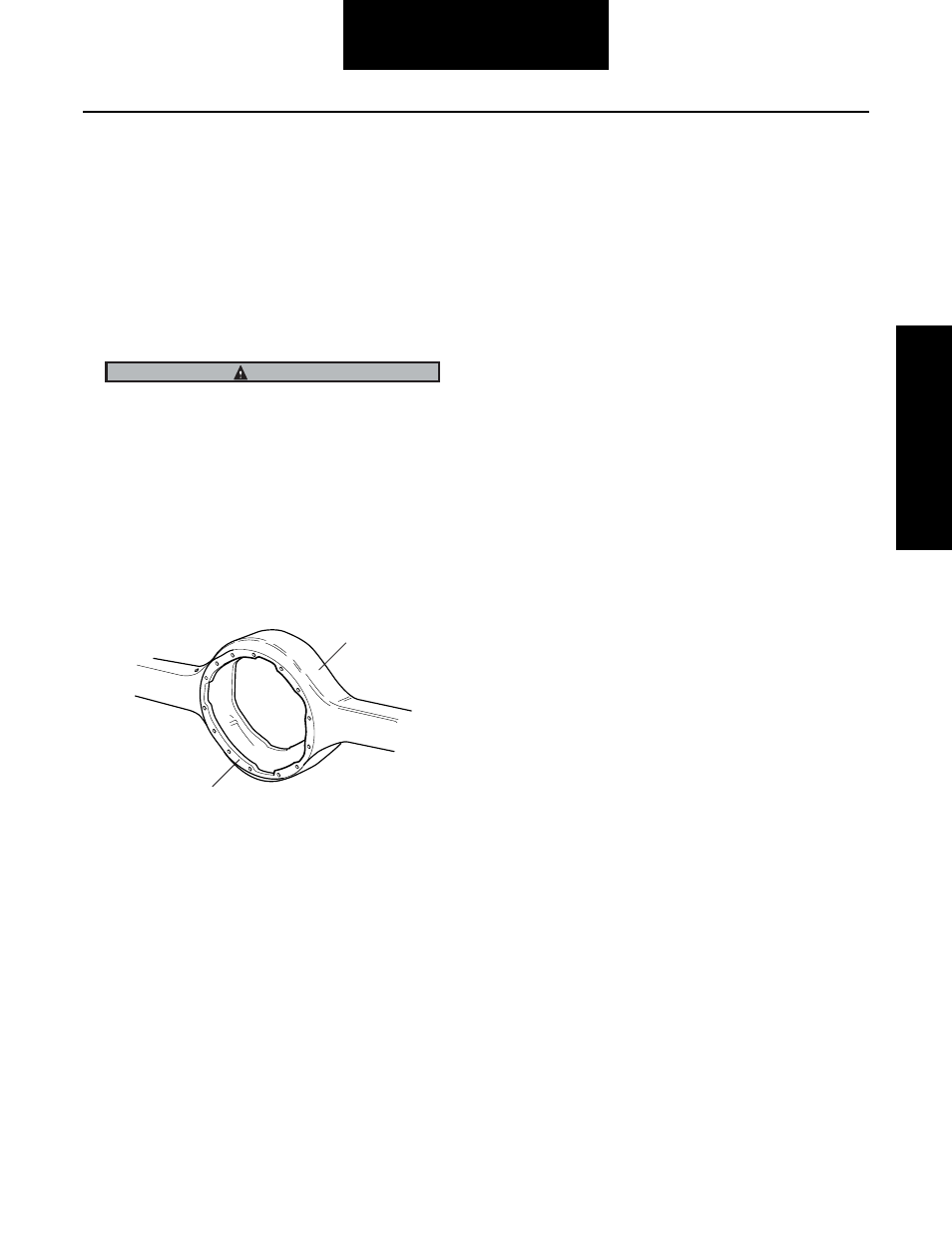

Axle housing inspection and repairs are limited to the

following checks or repairs.

•

Visually inspect axle housing for cracks, nicks, and

burrs on machined surfaces.

•

Check carrier bolt holes and studs for foreign

material.

•

Replace damaged fasteners. Look for loose studs or

cross threaded holes.

Any damage which affects the alignment or structural integ-

rity of the housing requires housing replacement. Do not

repair by bending or straightening. This process can affect

the material's properties and cause it to fail completely

under load.

•

Check all seals and gaskets.

Note: Replace conventional gaskets with silicone rubber

gasket compound (included in many repair kits). The

compound provides a more effective seal against lube

seepage and is easier to remove from mating surfaces

when replacing parts.

Inspect Components

Inspect all steel parts for:

•

Notches, visible steps or grooves created by wear

•

Pitting or cracking along gear contact lines

•

Scuffing, deformation, or discolorations. These are

signs of excessive heat in the axle and are usually

related to low lubrication levels or improper lubrica-

tion practices.

In addition, inspect the following for damage:

•

Differential gearing.

•

Bearings for loose fit on drive pinion, pilot bearing,

and differential bearings.

•

All fasteners for rounded heads, bends, cracks, or

damaged threads.

•

Inspect machined surfaces of cast or malleable

parts. They must be free of nicks, burrs, cracks,

scoring, and wear.

•

Look for elongation of drilled holes, wear on sur-

faces machined for bearing fits and nicks or burrs in

mating surfaces.

Inspect Primary Gearing

Before reusing a primary gear set, inspect teeth for signs of

excessive wear. Check tooth contact pattern for evidence of

incorrect adjustment.

CAUTION

1

2

1 - Axle housing

2 - Machined surface