Installation info – MSD 50953 Chevy High Speed DynaForce Starter 10 Pitch_139 Tooth Installation User Manual

Page 3

INSTALLATION INSTRUCTIONS

3

M S D

• W W W . M S D P E R F O R M A N C E . C O M • ( 9 1 5 ) 8 5 7 - 5 2 0 0 • F A X ( 9 1 5 ) 8 5 7 - 3 3 4 4

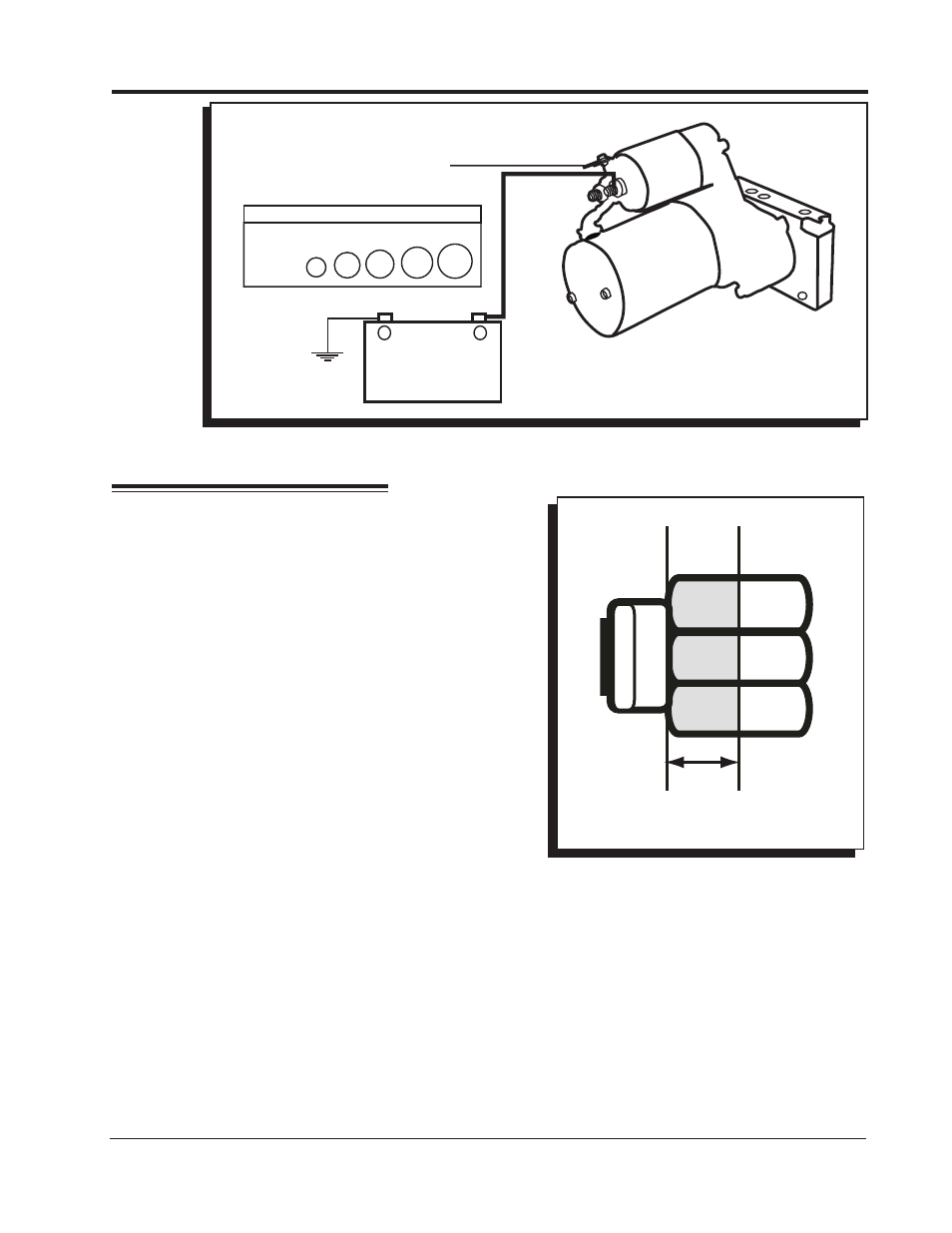

Figure 5 Wiring the Starter.

INSTALLATION INFO

INSPECT PINION GEAR

After cranking the engine several times, you can inspect

the witness pattern on the pinion gear. The pattern should

show 1/4" to 3/8". If over, the internal shim is required.

See Figure 3.

NOISE

If there is a high pitch whine during cranking, the pinion to

ring gear engagement may be out of specification, on the

high side. If there is a whine after cranking there may be

too little of clearance. The gear mesh spec is .020"-.035"

(Figure 4).

SLOW CRANKING

The most common cause is due to low input voltage. The

battery should be checked, but also inspect the battery

wires, terminals, connections or switches.

DISCONNECT SWITCHES

Most sanctioning bodies require an emergency disconnect

switch. Be sure to use a heavy duty switch that is capable

of handling high current. Some starters may pull over

700 amps while cranking. Most disconnect switches are

rated at continuous and intermittent amps. Make sure to use a switch that exceeds your starting and

electrical system requirements.

CAST IRON STARTERS

The MSD DynaForce Starter is meant to replace factory starters that were equipped with a aluminum

front housing (nose). If your original starter was cast iron, more shims may be required to achieve

proper ring gear engagement.

Figure 6 Pinion Gear Pattern.

THE CORRECT PINION DEPTH

SHOULD MEASURE 1/4” to 3/8”.

Image of starter

needs to be more

Chevy like in

this case.

image on page 1

or this....

and

should it be the

square thingie

BATTERY

+

-

LENGTH

3’

5’

7’

10’

+10’

AWG

4

2

1

0

00

CABLE LENGTH VS. GAUGE

12-GAUGE MINIMUM

TO IGNITION

SWITCH