MSD 50922 Ford High Speed DynaForce Starter BB 351M, 400, 429 Installation User Manual

Page 2

2

INSTALLATION INSTRUCTIONS

M S D

• W W W . M S D P E R F O R M A N C E . C O M • ( 9 1 5 ) 8 5 7 - 5 2 0 0 • F A X ( 9 1 5 ) 8 5 7 - 3 3 4 4

Figure 4 Wiring the DynaForce High Speed Starter.

BATTERY

+

-

LENGTH

3’

5’

7’

10’

+10’

AWG

4

2

1

0

00

CABLE LENGTH VS. GAUGE

12-GAUGE MINIMUM

TO IGNITION

SWITCH

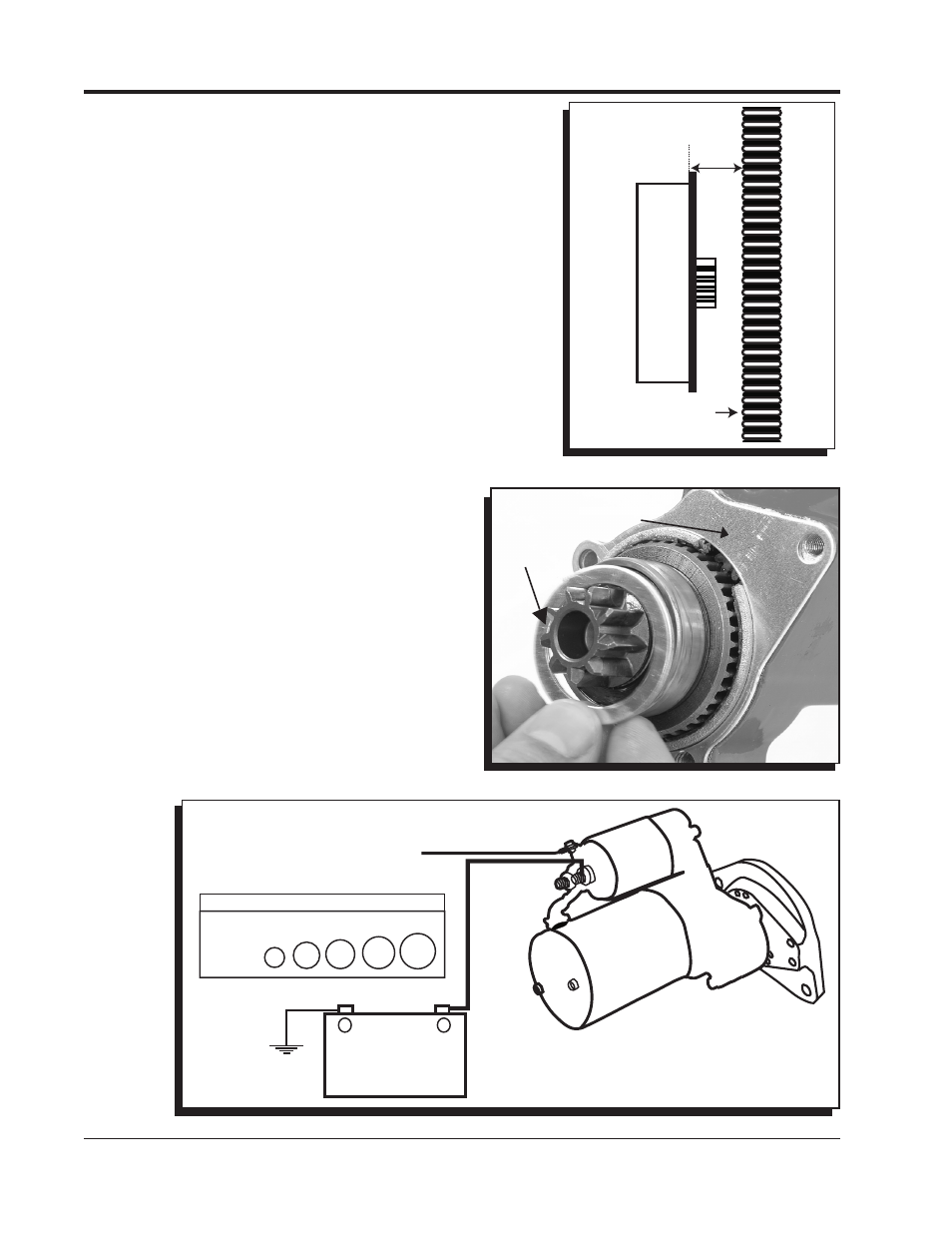

Figure 3 Installing the Pinion Shim Spacers.

INSTALL OUTER

SHIM

SHIM

RING

4. After confirming clearances and positioning. Mount the

starter.

• If there is not enough clearance, you will need to install

the supplied shim kit by removing the mounting block

(Figure 3). Place the small shim ring in the bearing bore

and install the outer shim on the support housing. Reinstall

the mounting block. This will move the pinion gear into the

starter approximately 0.060".

• The gear mesh is not adjustable on this application. Verify

that all parts are correct for the application (flywheel, block

plate, starter) and verify starter is mounted correctly to

engine plate.

5. The switch wire that connects to the solenoid should be at

least 12-gauge (Figure 4). For alternative wiring to incorporate

the factory remote solenoid, See Figure 5.

6. Attach the battery cable. The gauge of the battery cable

depends on its length. Using the proper gauge wire is

important to the operation of the starter. Both the positive and

ground wires must be able to meet the demands of the starter.

The chart in Figure 5 shows the recommended

sizes. Be sure to route the wire away from the

exhaust and moving parts of the engine.

7. Connect the battery terminals and start the

engine.

IMPORTANT: Never operate a starter for more than

30 seconds at a time without letting it

cool for at least two minutes.

Figure 2 Checking Pinion Clearance.

STARTER

MOUNTING

BLOCK

RING

GEAR

5/8” -

11/16”