MSD 8489 Chevy Crab Cap Crank Trigger Distributor Installation User Manual

Page 2

2

INSTALLATION INSTRUCTIONS

M S D

• W W W . M S D P E R F O R M A N C E . C O M • ( 9 1 5 ) 8 5 7 - 5 2 0 0 • F A X ( 9 1 5 ) 8 5 7 - 3 3 4 4

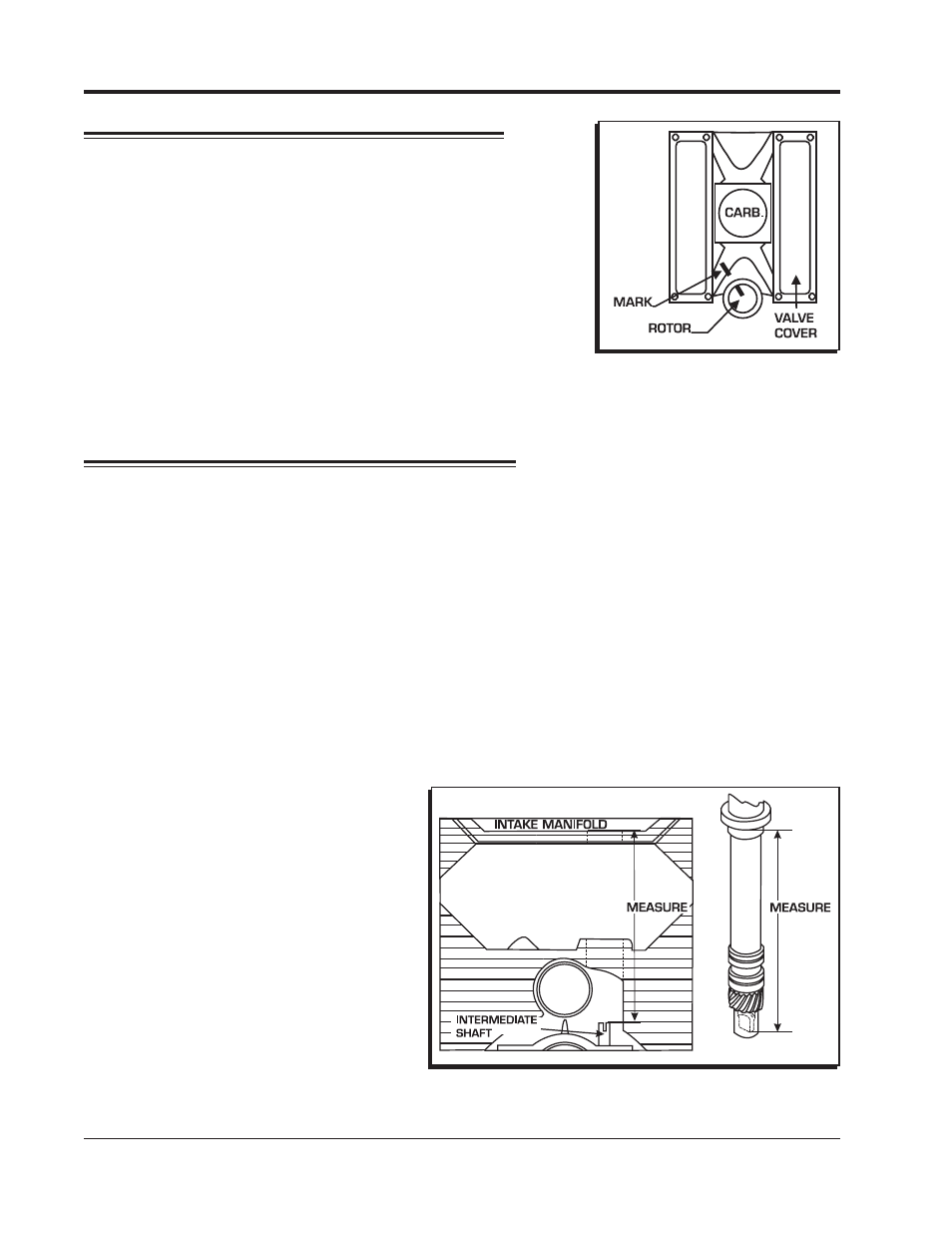

Figure 3 Checking Oil Pump Shaft to the

Distributor Shaft Overlay.

REMOVING THE DISTRIBUTOR

1. Remove the existing distributor cap without disconnecting any

of the spark plug wires.

2. With the cap off, rotate the engine or until the rotor is aimed at a

fixed point on the engine or firewall. Note this position by making

a mark (Figure 2).

3. Place the distributor cap back on and note which plug wire the

rotor is pointing to. MARK THE SPARK PLUG WIRES and remove

the distributor cap.

4. Loosen the distributor hold-down clamp and slide the clamp

out of the way.

5. Lift the distributor out of the engine. Note that the rotor rotates

as you lift the distributor out. This is due to the helical cut gear and

should be taken into consideration when installing a new distributor.

PREPARING THE DISTRIBUTOR

The MSD Billet Distributor features an adjustable slip collar. This collar provides an adjustment to

accomodate variations in block height, modified intakes or heads. It is recommended to check the

slip collar setting before installation. MSD offers a special tool, the 3-In-1 Distributor Set Up Tool, PN

8599, to make these adjustments accurately. If the tool is not available, follow this procedure.

ADJUSTING THE SLIP COLLAR

1. Loosen the slip collar and insert the distributor into the engine until it bottoms out against the oil

pump drive.

2. After it bottoms out, raise the distributor 0.010" - 0.030" then slide the slip collar down into the

position and tighten it.

CHECKING THE OIL PUMP TO DISTRIBUTOR SHAFT OVERLAP

The proper overlap between the distributor shaft and the oil pump shaft is very important. The tongue

of the distributor shaft should fit into the groove of the oil pump shaft by at least 1/4". To check this:

CHECKING GEAR MESH

It is recommended to check for proper gear

mesh between the cam gear and distributor

gear. To do this, coat the distributor gear

with moly grease and install the distributor.

Figure 2 Marking the Rotor Location.

1. Measure the distance between the base

of the slip collar to the tip of the distributor

shaft (Figure 3).

2. Using a straight edge, measure the

distance from the intake manifold

distributor flange to the top of the oil pump

intermediate shaft (Figure 3).

3. Take the two measurements and subtract

them. The difference is the overlap. If

there is not enough clearance or too much

clearance, a different oil pump shaft is

required.