MSD 8503 Ford 289, 302 E-Curve Pro-Billet Distributor Installation User Manual

Page 2

2

INSTALLATION INSTRUCTIONS

M S D

• W W W . M S D P E R F O R M A N C E . C O M • ( 9 1 5 ) 8 5 7 - 5 2 0 0 • F A X ( 9 1 5 ) 8 5 7 - 3 3 4 4

Electronic Centrifugal Advance: Since this distributor is all electronic, there really is no mechanical

or centrifugal advance. On a standard distributor, this advance would be called centrifugal so it will

be referred to as the electronic centrifugal advance. The chart on page 4 shows all of the different

combinations you can achieve by simply turning the two rotary dials located under the distributor cap.

Total Timing: This is the total amount of timing that the engine will achieve. This is the amount that

all of the electronic curve and settings will be based from. This setting also includes any amount of

vacuum advance that you plan to use.

Vacuum Advance: The vacuum advance will advance the timing under part throttle conditions when

the engine is not under a heavy load. This advance is added on to the electronic timing curve as

well. The advance will begin as low as 4-in. of vacuum and will max out at 10-in. of vacuum. There is

a separate chart in Figure 3 that illustrates the vacuum curve selection.

Locked-Out Timing: If you do not want to have a timing advance, set the rotary dials in the Locked-

Out position. This means the timing will not move from the setting you position the distributor in. You

may however, take advantage of a start retard (see below).

Start Retard: When you select Locked-Out timing, the engine may be hard to crank. A start retard

amount can be selected to aid in cranking. This amount can range from 5°, 10°, 15° and 20°. When

the engine is cranking, the timing will be retarded. Once the engine reaches 600 rpm, the timing will

return to the locked-out setting.

Note: The total amount of any timing change that can be achieved is 34° (25° for the electronic

advance with vacuum an additional 9°). This includes the electronic advance as well as the

vacuum advance.

Note: It is recommended to have a dial-back timing light, timing tape or a fully degreed balancer to

set the timing correctly.

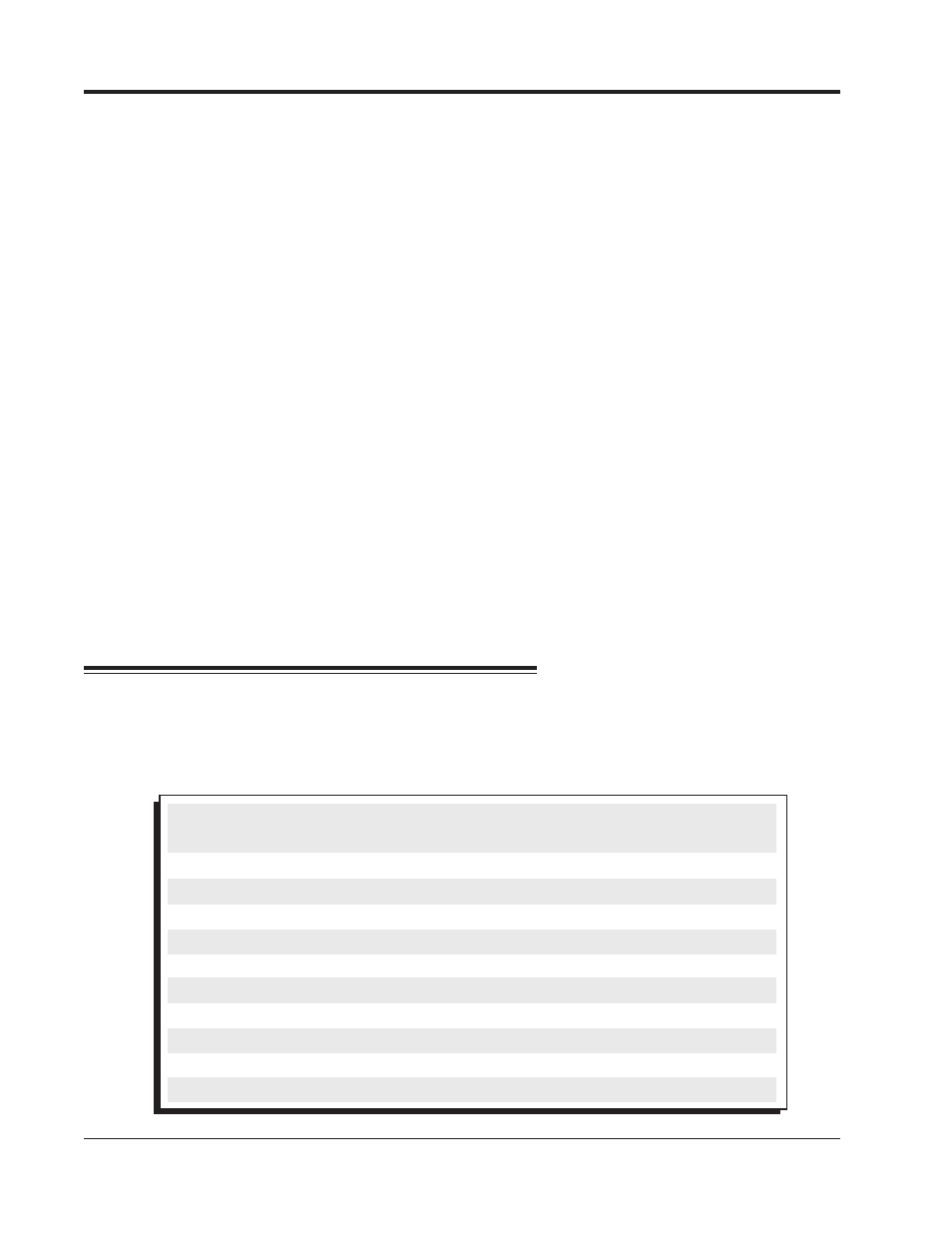

CHOOSING AN ADVANCE CURVE

The function of the advance curve is to match the ignition timing to the burning rate of the fuel with

the speed (rpm) of the engine. The piston is traveling much faster through the combustion stroke at

5,000 rpm compared to 1,000 rpm. Any factor that changes the burning rate of the fuel or the engine

speed can cause a need for an ignition timing change. Figure 2 shows some of the factors that will

affect engine timing.

FACTOR

Advance Timing

Retard Timing

For

For

Cylinder Pressure

Low

High

Vacuum

High

Low

Energy of Ignition

Low

High

Fuel Octane

High

Low

Mixture (Air/Fuel)

Rich

Lean

Temperature

Cool

Hot

Combustion Chamber Shape

Open

Compact

Spark Plug Location

Offset

Center

Combustion Turbulence

Low

High

Load

Light

Heavy

Figure 2 Ignition Timing Factors.