Cz`<<`.hc zt.%.`.hc, Specification, 4 checking the protective anode – STIEBEL ELTRON SH A с 01.03.2009 User Manual

Page 24: 5 descaling the flange, 6 anti-corrosion protection, 1 dimensioned drawing

ŝÔ

Z+

qqqĪZ`. <é<`VHCĪHB

.CZ`<<`.HC

ZT.%.`.HC

15.4 Checking the protective anode

»

Check the protective anode after the first 2 years of use and

replace if necessary. To do this you must dismantle the flanged

immersion heater.

»

Afterwards determine the time intervals at which further checks

should be carried out.

The transition resistance between the protective anode and

cylinder connector may be no more than 1.0 Ω.

15.5 Descaling the flange

»

Only descale the flange after disassembly and never treat the

cylinder surface and protective anode with descaling agents.

15.6 Anti-corrosion

protection

Ensure when carrying out service work that the anti-corrosion

protection on the insulating plate is not damaged or removed.

Reinsert the anti-corrosion protection correctly after replacement.

1

4

2

3

4

2

6

_0

2_0

1

_0

2

2

8

1 Anti-corrosion protection

2 Pressure plate

3 Insulating plate

4 Copper flanged immersion heater

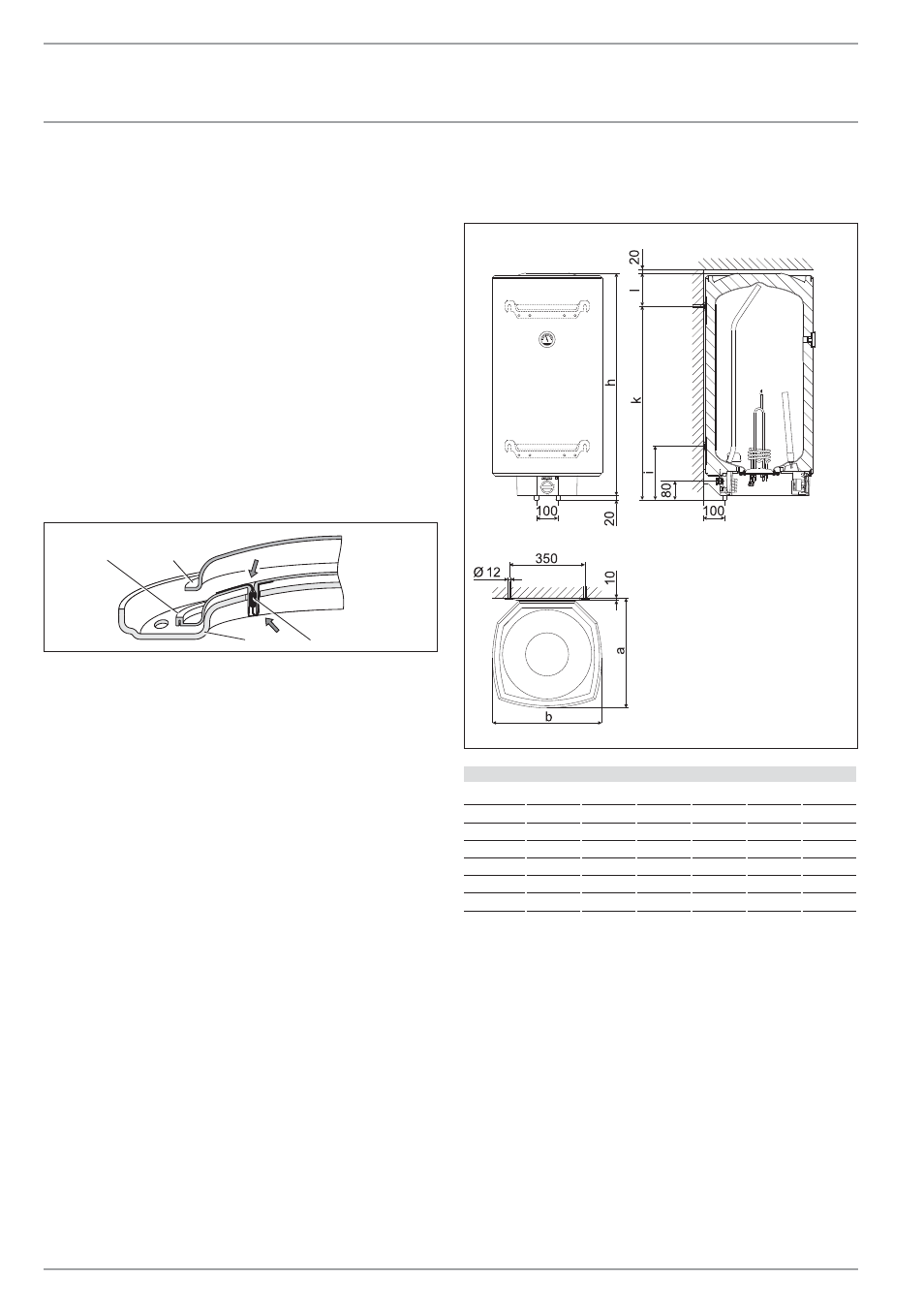

16. Specification

16.1 Dimensioned

drawing

2

6

_0

2_0

1

_0

5

7

8

êă¼ĉńêĒĉń

Type

SH 50 A

SH 80 A

SH 100 A

SH 120 A

SH 150 A

Dimension a

mm

510

510

510

510

510

Dimension b

mm

510

510

510

510

510

Dimension h

mm

720

955

955

1 080

1 260

Dimension i

mm

-

-

-

300

300

Dimension k

mm

600

900

900

900

1 100

Dimension l

mm

140

75

75

200

180