Ridge tool company 2, Warning – RIDGID RP 300-B User Manual

Page 3

RP 100-B, RP 300-B

Ridge Tool Company

2

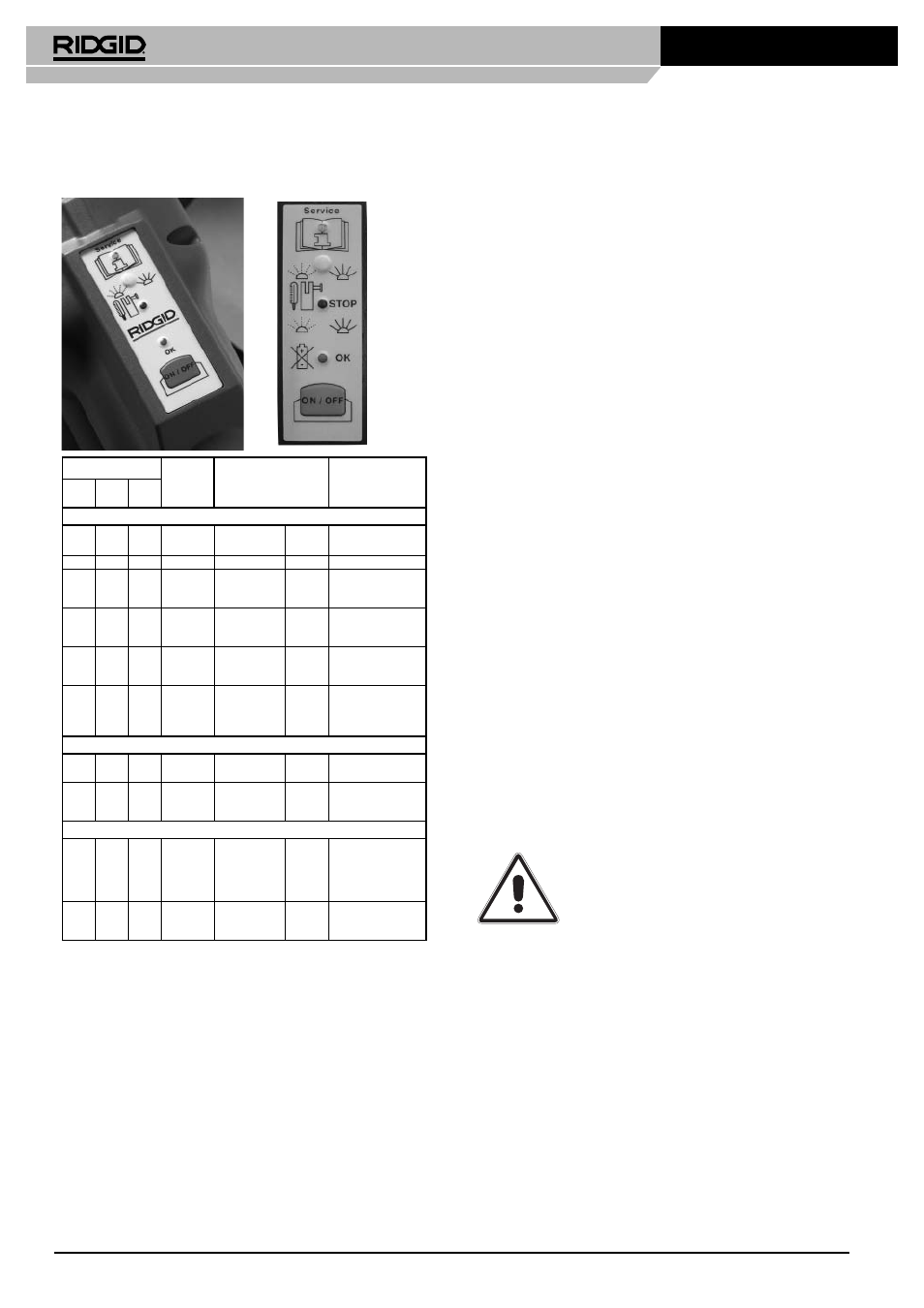

TROUBLESHOOTING

LED display

Acoustics

Status

Action

green

red

yellow

RP 100-B and RP 300-B

lit

lit

lit

short beep

(300-B)

ON/OFF switch

being pressed

Machine

activated

–

lit

–

–

–

All O.K.

–

lit

–

blinks

–

All O.K. after

20,000 pressings

Service

required

Inspection and main-

tenance by authorized

service center

lit

blinks

–

–

Retaining bolt

not inserted

completely

Machine

blocked

Insert retaining bolt

correctly

lit

blinks

–

–

Temperature out

of range

Machine

blocked

Bring machine within

temp. range of -5°C

and +50°C

–

lit

lit

beeps

5 sec.

(300-B)

6 consecutive

times pressure

not reached or

time exceeded

Machine

blocked

= service

Inspection and main-

tenance by authorized

service center

RP 300-B ONLY

blinks

3 times

–

–

–

Pressing O.K.

–

–

–

lit

–

Maintenance

after 22,000

pressings

Machine

blocked

Inspection and main-

tenance by authorized

service center

RP 100-B ONLY

blinks blinks

–

–

Low battery tool

overheated or

excess current

Replace or recharge

battery. Allow tool to

cool. If condition repeats

inspection by authorized

service center

lit

–

lit

–

Maintenance

after 22,000

pressings

Machine

blocked

Inspection and main-

tenance by authorized

service center

• If there is a power supply interruption during pressing procedure, the

machine stops and the pistons will be brought into the original position

after a few seconds.

Note:- for 100-B press black release button on side of tool.

• Whenever a pressing cycle is not fully completed the complete procedure

must be repeated.

• It is strongly recommended to never attempt to repeat a pressing cycle

that has been interrupted. This may lead to damage to the joint and pos-

sible leakage. The joint should be cut out and replaced by a new one.

• The use of jaws not specifi cally designed for pressing the fi ttings being

used may lead to damage and incorrectly compressed fi ttings. Contact

your RIDGID Press Fit Service Centre for any malfunction not covered in

this instruction manual.

MAINTENANCE

Always remove the battery before performing any maintenance.

Daily

- Clean the Press Fit tool with a soft cloth. Do not use detergents to clean

the crimping tool. Check the condition of the tool and ensure that the

press rolls (Fig.1, ref. 6) are free of metallic particles. Use lubricating and

corrosion prevention spray if they appear dry.

Every 20,000 pressings (or every 3 years)

- The Press Fit tool must be sent for inspection and maintenance to the

nearest authorized RIDGID Press Fit repair centre. After 20,000 cycles a

warning signal will indicate that the tool should be serviced (see trouble-

shooting).

- The repair centre will fully overhaul the tool and inspect that it is opera-

ting correctly.

- Any unauthorized modifi cations and/or repairs will invalidate the warranty.

Storage

- Before storing the tool for long periods clean the tool thoroughly and wipe

clean.

- Keep the tool away from moisture and heat, and do not expose the tool

to extreme temperatures.

- Keep away from children.

- The RIDGID Press Fit tool is made of numerous metal and plastic parts.

Ensure that the tool is correctly disposed of in accordance with local

regulations.

Fig. 1

1 ON/OFF

switch

2 LED display green, red and orange

3 Trigger switch – starts automatic pressing cycle

4 Tool

identifi cation plate with serial number

5 Press jaw holder with 90° rotation

6 Press

rolls

7 Lock

pin

8 Press

jaw

9 Plastic

housing

10 Battery 14.4 V / 2.6 Ah

WARNING!

Keep fi ngers and hands away from jaws during

pressing cycle!

Fingers or hands can be crushed, fractured or

amputated if they become caught between the jaws.

Always verify that the jaw is correctly fi tted in the

press tool and that the locking pin is fi rmly closed.

IMPORTANT:

This jaw set is designed to make Press Fit connections for the specifi c

system and size noted on the jaw set and packaging.

Follow fi tting manufacturer’s recommendations on proper installation.

The use of incorrect jaw sets for a system or size will result in an

improper seal that could result in extensive property damage.