Operations, E. co diluted to oxygen reference, Switch the instrument on – RIDGID FG-100 User Manual

Page 6: D. engineering units, Set the right fuel for the boiler, Pressure draft procedure, A. internal pressure sensor

E. CO diluted to Oxygen reference

The CO undiluted (0% O ) setting is standard set. Use the procedure below

if a different reference value is required.

2

Select the parameter for changing, pressing

Confirm the selection pressing the key

Set

value, pressing

the reference

Confirm changes pressing the key

Press:

F1

Select and confirm the “O2 reference” option.

Wait the 60 seconds countdown

for the autozero procedure.

DO NOT INSERT THE PROBE IN THE STACK

To mute the beep

1. Switch the Instrument ON

OPERATIONS

D. Engineering units

Technical unit for gas, temperature and pressure can be set.

F1

Select the parameter for changing, pressing

Confirm the selection pressing the key

Set

value, pressing

Day , Month or Year

Confirm changes pressing the key

Press:

5

ATTENTION:

Be sure that the boiler room is well vented and secure from CO.

Before entring in the boiler room check the ambient CO concentration.

–

ENGINEER UNITS

> CO

ppm

Other

ppm

Temp.

°C

Pres.

hPa

ESCAPE

The fuels can be changed.

Up to 10 fuels can be set using GasConfig PC software and the USB cable.

Select the Fuel from a list pressing

Confirm the selection pressing the key

Press:

Select and confirm the “--- FUEL ---” option.

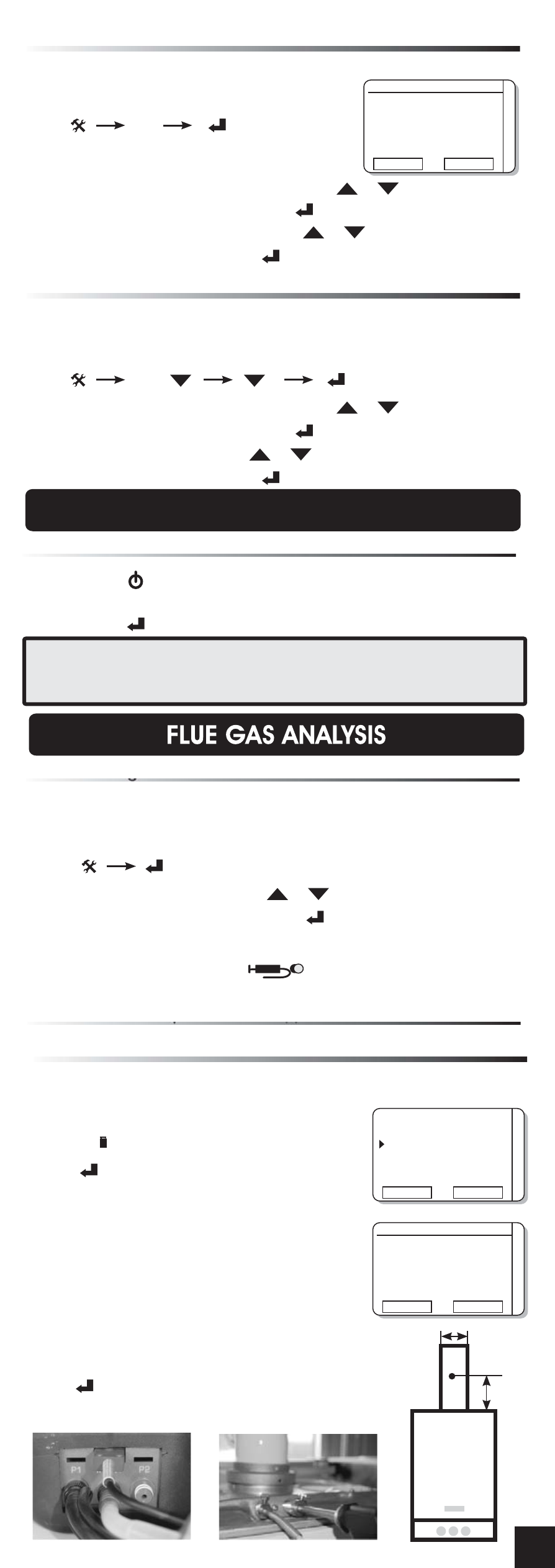

1. Set the right fuel for the boiler

Press

(F2) to start the flue gas analysis

ESCAPE

6

To pause the analysis press the

button. This will stop the internal

pump. Press

(F2) to restart the flue gas analysis.

ESCAPE

2. Pressure Draft procedure

- applicable for natural draft boiler

REMOVE THE PROBE FROM THE STACK

A. Internal pressure sensor

Differential pressure and draft can be measured using the internal

pressure sensor (P1 - P2) inlet. Do not exceed 200mbar input.

Press

to select the Internal Sensor input

F1

Press

to input the ambient temperature

Press

“ZERO” to reset the display indication.

Wait for stabilization of the measurement.

Press

to save the measured value.

Value will printed on the report.

Press

to exit to the previous menu.

FI

F2

Insert the probe inside the standard

boiler holes (see figure). If the boiler do not have

them, insert the probe as shown in the drawing.

2 x D

D

–

F1=Internal sensor

F2=External sensor

TaE

23.00

INT

EXT

–

DRAUGHT

Measure

1.0 mbar

Press [ENTER]

To save measure

ZERO

ESCAPE

Press

#

DP