RIDGID 690 User Manual

Page 3

Ridge Tool Company

Tools For The Professional

TM

600-690

TROUBLE SHOOTING

Warning

Each remedy with has to be repaired by a qualified electrical craftsman.

Disconnect power cord.

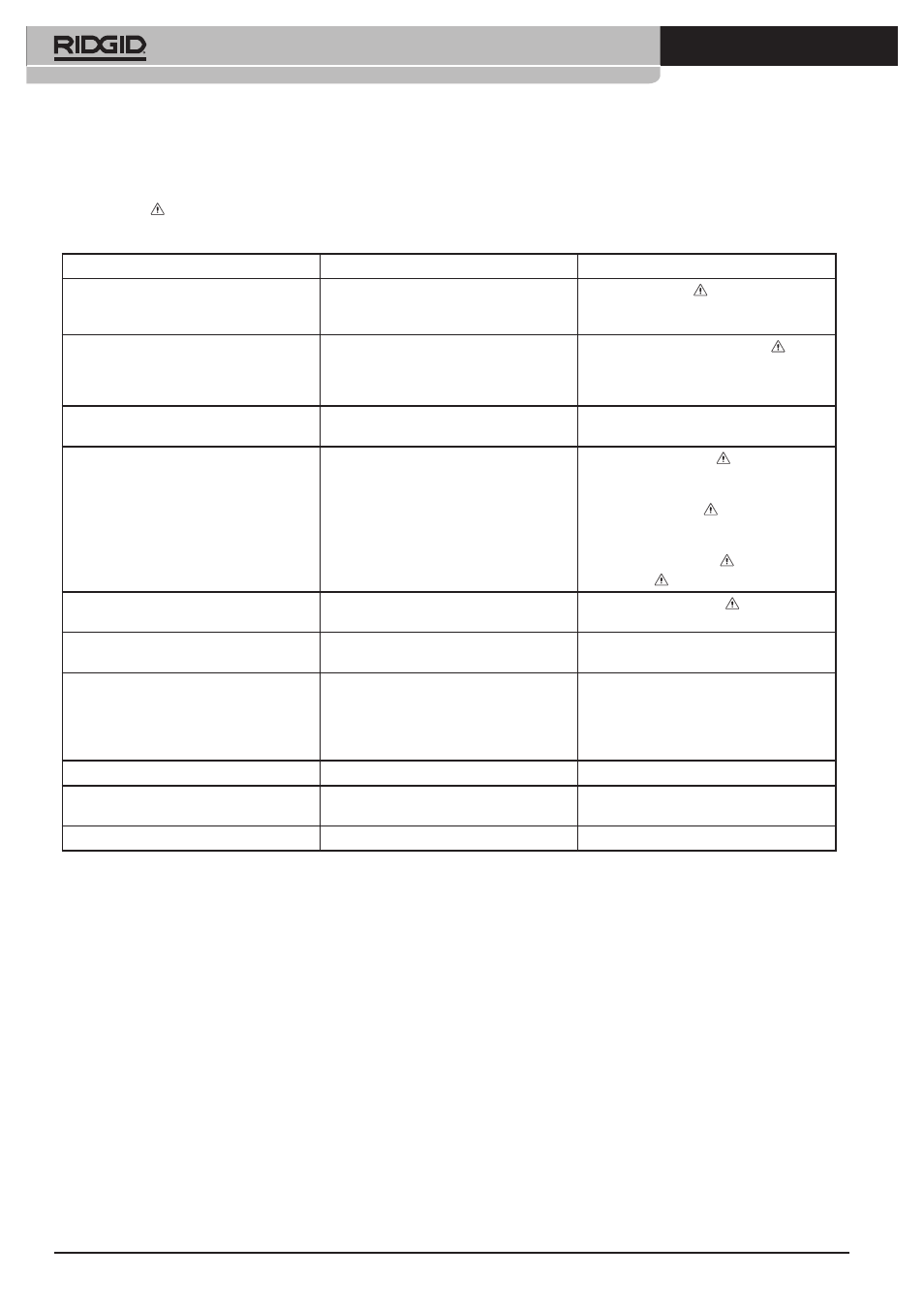

TROUBLE SHOOTING

POSSIBLE CAUSE

REMEDY

- motor does not start

- interruption of supply

- fuse has been blown

- brushes do not touch armature

- examine the supply

- install a new fuse

- check the brushes, renew used brushes

- motor cannot be loaded

- short circuit

- overload because of dull dies

- bad quality or insufficient thread cutting oil

- look for the short circuit and resolve

- renew the dies

- use RIDGID thread cutting oil in adequate

quantity

- abnormal heating of the motor

- overload because of dull dies

- insufficient cooling air

- renew dies

- clean the air-vent opening of the motor

- sparks forming at the motor

- dirty commutator

- bad contact between brushes and brush holder

- because of excessive wear brushes do not

touch commutator properly

- brushes of different manufacture

- sharp edge of brush

- please send in for repair

- tighten the screws, make sure brush is pressed

firmly onto commutator

- change worn brushes

(replace only with genuine commutator properly

RIDGID brushes)

- only use original brushes

- break edge

- “sparks” in the motor compartment

- particles come loose from brushes or armature

(collector) and start glowing

- send machine in for repair

- die head does not start threading

- dull or broken dies

- machine running in wrong direction

- change dies

- check setting of the direction switch

- damaged thread

- dull dies

- dies not assembled in correct sequence

- low quality pipe

- bad quality or insufficient thread cutting oil

- change dies

- put dies in correct sequence

- make sure only pipe of good quality is used

- use only RIDGID thread cutting oil in adequate

quantity

- support arm turns while threading

- support arm jaws dirty

- clean with wire brush

- die heads cannot be changed properly

- burr has occurred at the spline end of the die

head

- eliminate burr with file

- die head not held tightly

- retaining spring damaged or worn

- replace retaining spring