York CHAMPION D2EB User Manual

Page 4

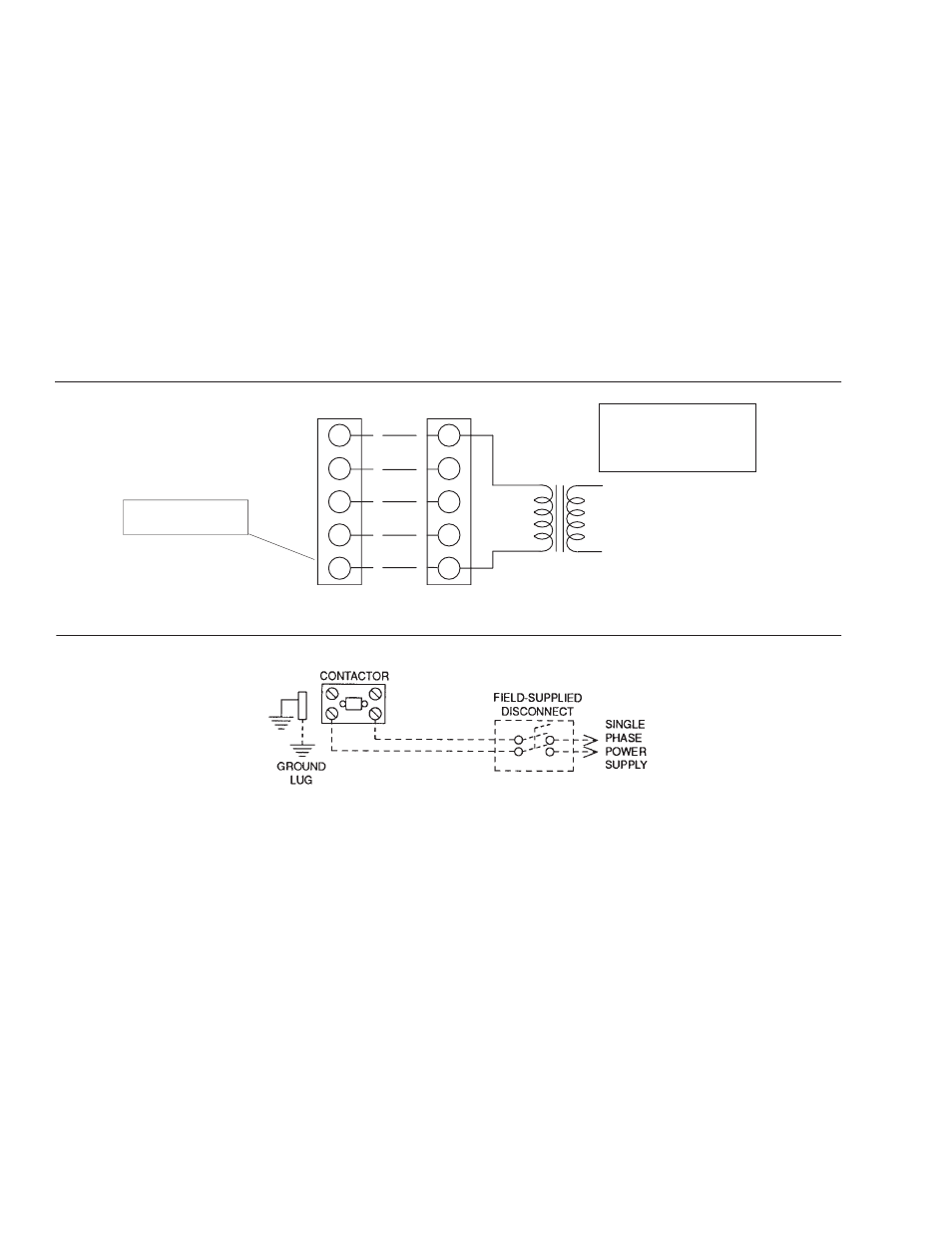

POWER AND CONTROL WIRING

Field wiring to the unit must conform to provisions of the current

N.E.C. ANSI/NFPA No. 70 or C.E.C. and/or local ordinances.

The unit must be electrically grounded in accordance with local

codes or, in their absence, with the N.E.C./C.E.C. Voltage toler-

ances which must be maintained at the compressor terminals

during starting and running conditions are indicated on the unit

Rating Plate and Table 3.

The wiring entering the cabinet must be provided with me-

chanical strain relief.

A fused or HACR breaker disconnect switch should be field pro-

vided for the unit. If any of the wire supplied with the unit must be

replaced, replacement wire must be of the type shown on the wir-

ing diagram.

Electrical line must be sized properly to carry the load. Each

unit must be wired with a separate branch circuit fed directly

from the meter panel and properly fused.

Refer to Figure 2 for typical field wiring and to the appropriate unit

wiring diagram for control circuit and power wiring information.

COMPRESSORS

Units are shipped with compressor mountings factory-adjusted

for shipping.

CAUTION: Loosen compressor mounting bolts

half turn before operating unit.

174065-YIM-A-0206

4

Unitary Products Group

FIG. 2 - TYPICAL FIELD WIRING DIAGRAM

POWER WIRING

4

/

9

4

/

+

;

;

9

+

24 VOLT TRANSFORMER

UNIT TERMINAL STRIP

THERMOSTAT

NOTE:

HEAT ANTICIPATOR

SHOULD BE SET AT 0.25

AMPS FOR ALL MODELS.

CAUTION: Label all wires prior to disconnection when servicing controls. Wiring errors can

cause improper and dangerous operation. Verify proper operation after servicing.

PROGRAMMABLE

THERMOSTAT ONLY

CONTROL WIRING

** = Minimum wire size of 18 AWG

wire should be used for all field

installed 24 volt wire.

**

*

* = Only required on units with

supplemental electric heat.

REFER TO ELECTRICAL DATA

TABLES TO SIZE THE DISCON-

NECT SWITCH, WIRING &

OVERCURRENT PROTECTION.