Installation – York CHAMPION D2EB User Manual

Page 2

LIMITATIONS

These units must be installed in accordance with the following

national and local safety codes.

1. National Electrical Code ANSI/NFPS No. 70 or Canadian

Electrical Code Part 1, C22.1 (latest editions).

2. Local plumbing and waste water codes and other applica-

ble local codes.

Refer to Table 1 for unit application data and to Table 5 for elec-

tric heat application data.

If components are to be added to a unit to meet local codes, they

are to be installed at the dealer's and/or the customer's expense.

Size of unit for proposed installation should be based on heat

loss/heat gain calculations made in accordance with industry

recognized procedures identified by the Air Conditioning Con-

tractors of America.

LOCATION

Use the following guidelines to select a suitable location for

these units.

1. Unit is designed for outdoor installation only.

2. Condenser must have an unlimited supply of air. Where a

choice of location is possible, position unit on either north or

east side of building.

3. For ground level installation, a level pad or slab should be

used. The thickness and size of the pad or slab used should

meet local codes and unit weight. Do not tie the slab to the

building foundation.

4. For roof top installation, be sure the structure will support

the weight of the unit plus any field installed components.

Unit must be installed on a level roof curb or appropriate an-

gle iron frame providing adequate support under the

compressor/condenser section.

5. Maintain level tolerance of unit to 1/8" maximum.

RIGGING OR HANDLING

Care must be exercised when moving the unit. Do not remove

any packaging until the unit is near the place of installation. Rig

unit with slings placed under the unit. Spreader bars of suffi-

cient length should be used across the top of the unit.

BEFORE LIFTING A UNIT, MAKE SURE THAT ITS WEIGHT

IS DISTRIBUTED EQUALLY ON THE CABLES SO THAT IT

WILL LIFT EVENLY.

Units may also be moved or lifted with a fork-lift. Slotted open-

ings in the skid are provided for this purpose. Forks must pass

completely through the base.

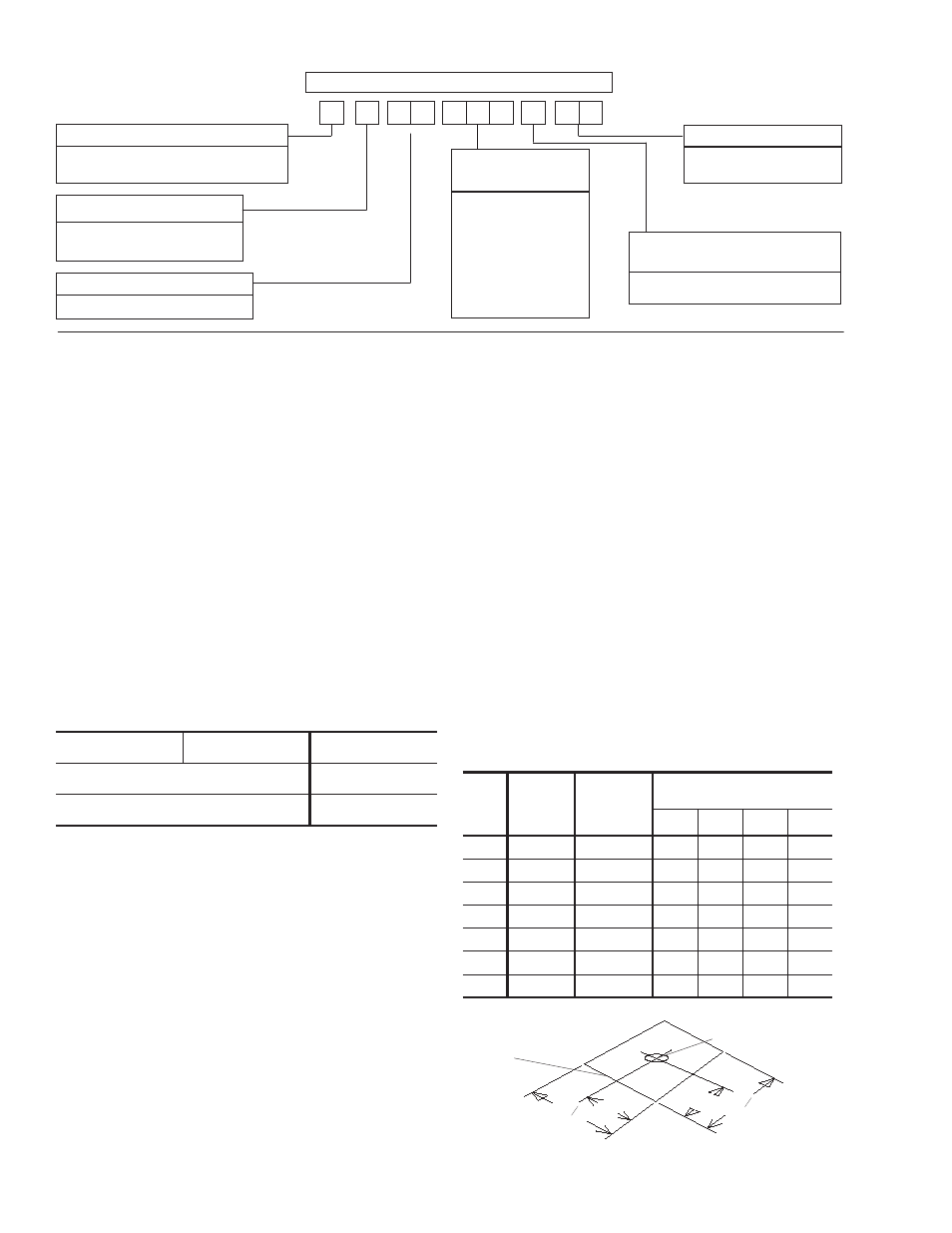

Refer to Table 2 for unit weights and to Figure 1 for approximate

center of gravity.

174065-YIM-A-0206

2

Unitary Products Group

Voltage Variation

Min. / Max

.1

208/230V

3

187 / 253

3

Wet Bulb Temperature (

°F) of Air on

Evaporator Coil,

Min. / Max.

57 / 72

Dry Bulb Temperature (

°F) of Air on

Condenser Coil,

Min.

2

/ Max.

45 / 120

Rated in accordance with ARI Standard 110, utilization range “A”.

A low ambient accessory is available for operation down to 0

°F

!

“T1" transformer primary tap must be moved from the 230 volt connection to the 208 volt

connection for low voltage applications of 208 volt and below.

TABLE 1 - UNIT APPLICATION DATA

FIG. 1 - CENTER OF GRAVITY

49

&

26

47

"

CENTER OF GRAVITY

FRONT

OF

UNIT

“A”

“B”

“C”

“D”

UNIT

SIZE

SHIPPING

WEIGHT

(lbs.)

OPERAT-

ING

WEIGHT

(lbs.)

CORNER WEIGHTS

(location, lbs.)

“A”

“B”

“C”

“D”

018

318

313

86

76

73

83

024

324

319

88

77

75

85

030

333

328

85

81

82

86

036

338

333

91

80

78

88

042

347

342

94

83

80

91

048

368

363

92

88

92

97

060

376

371

105

100

84

87

TABLE 2 - UNITS WEIGHTS

D

2

E

B

A

PRODUCT NOMENCLATURE

PRODUCT GENERATION

2 = 2nd Generation

PRODUCT CATEGORY

D = Single Package Air Conditioner

(Air Cooled)

PRODUCT IDENTIFIER

EB = 10 SEER Cooling Models

2

0

4

0

6

FACTORY

INSTALLED ELECTRIC HEAT

A = No Electric Heat Installed

VOLTAGE CODE

06 = 208/230-1-60

NOMINAL COOLING

CAPACITY (MBH)

018 = 18,000 BTUH

024 = 24,000 BTUH

030 = 30,000 BTUH

036 = 36,000 BTUH

042 = 42,000 BTUH

048 = 48,000 BTUH

060 = 60,000 BTUH

INSTALLATION