Dc cabling procedure – Xantrex Technology PROSINE PS3.0 User Manual

Page 65

Recommended DC Cable Sizes For Proper Operation

48

Prosine Installation & Operation Guide

DC Cabling Procedure

CAUTION Reversing the positive and negative battery cables will damage the Prosine inverter/

charger and void your warranty. This type of damage is easily detected. Before making the final

DC connection, check cable polarity at both the battery and the inverter/charger. Follow the procedure

outlined below to make your DC cable connections. Observe the polarities carefully while performing

the installation, and route both cables before making any connections.

1. Cut the cables to the correct length with enough insulation stripped off to properly

install the lugs.

2. If using compression lugs, attach the terminals to both cables using the crimp tool

recommended by the manufacturer of the ring terminals. There must be no stray wire

strands protruding from the terminal. If using box lugs, attach the lug to the Prosine

first, then insert the wire and tighten the set screw to the torque recommended by the lug

manufacturer.

3. Connect the positive cable to the positive battery connector (stud) on the Prosine

inverter/charger and tighten to a torque of 216–240 inch-pounds (24–27Nm) with a

wrench. Test that the cable is secure.

4. Install an inline fuse between the Prosine inverter/charger and the battery. Refer to the

tables to determine the fuse sizes required. This protects your battery and wiring in case

of accidental shorting. The fuse and fuse holder must be installed in the positive side of

the DC circuit, as close as possible to the batteries.

5. Connect the cable from the POSITIVE connector on the Prosine inverter/charger to the

POSITIVE (POS +) terminal on the battery fuse.

6. Connect the DC NEGATIVE cable to the NEGATIVE (NEG -) terminal on the battery.

7. Connect the DC NEGATIVE cable to the negative terminal on the inverter/charger. This

connection should be the last connection made. A spark when making this final

connection is normal.

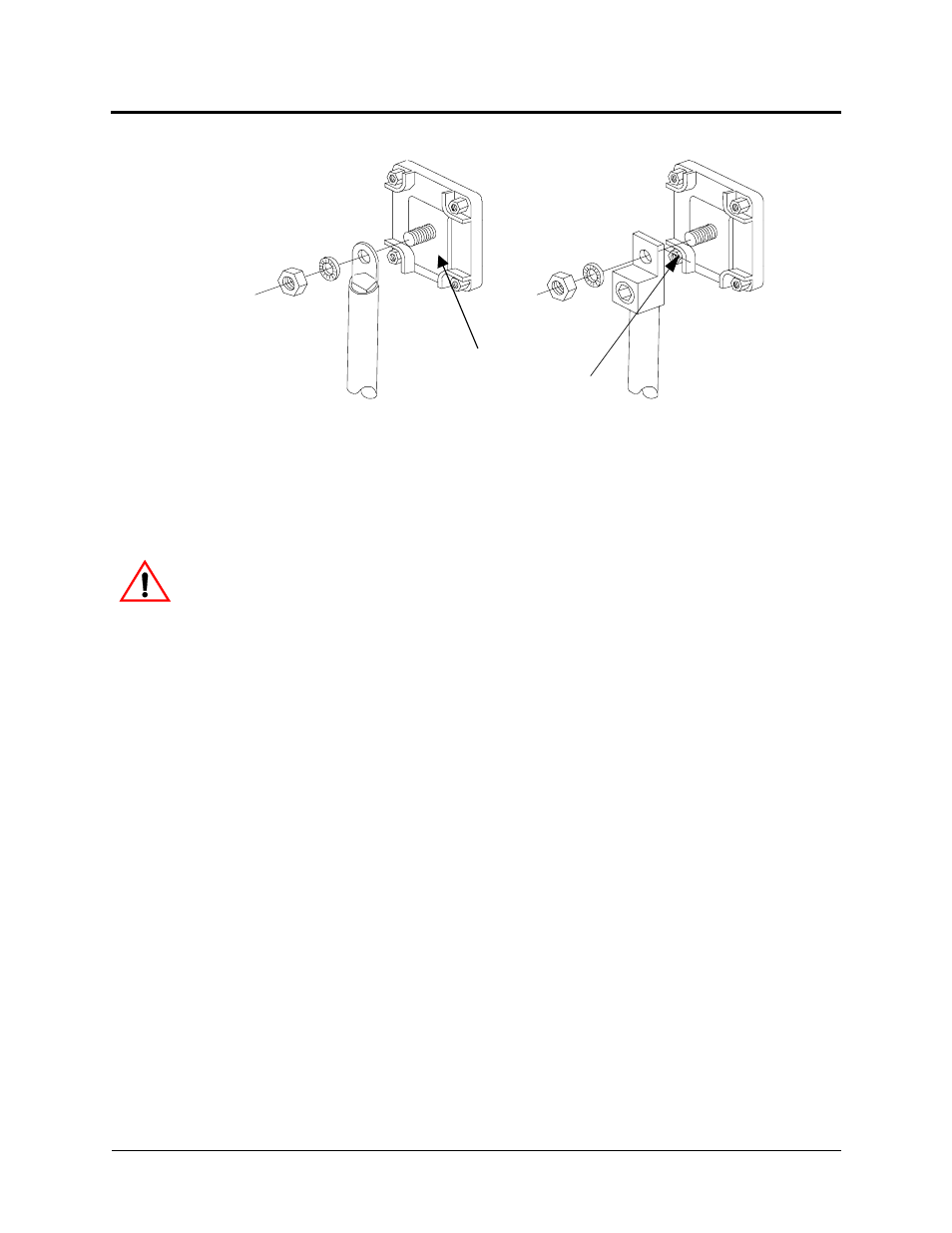

2/0 Copper Compression Lug

2/0 Aluminum Mechanical Lug

Do not place anything between

battery cable lug and terminal

surface. Assemble exactly as shown

Aluminum Box Lug

Copper Compression Lug