York E2FB120 User Manual

Page 7

Use hard drawn copper tubing where no appreciableamountof

bending around pipes or other obstructions is necessary. Use

long radius ells wherever possible with one exception - small

radius ells for the traps in all vapor risers. If soft copper is used,

care should be taken to avoid sharp bends which may cause a

restriction.

Pack fiber glass insulation and a sealing material such as

Permagum around refrigerant lines where they penetrate a

wall to reduce vibration and to retain some flexibility.

Support all refrigerant lines at minimum intervals with suitable

hangers, brackets or clamps.

Braze all copper to copper joints with Silfos-5 or equivalent

brazing material. Do not use soft solder.

Insulate all vapor lines with a minimum of 1/2" ARMA-FLEX or

equal. Liquid lines exposed to direct sunlight and/or high tem-

peratures must also be insulated.

Never solder vapor and liquid lines together. They can be taped

together for convenience and support purposes, but they must

be completely insulated from each other.

Never exceed the maximum line length listed in Table 1.

LINE SIZING

The following factors should be considered when locating the

indoor and outdoor units and when sizing the refrigerant lines

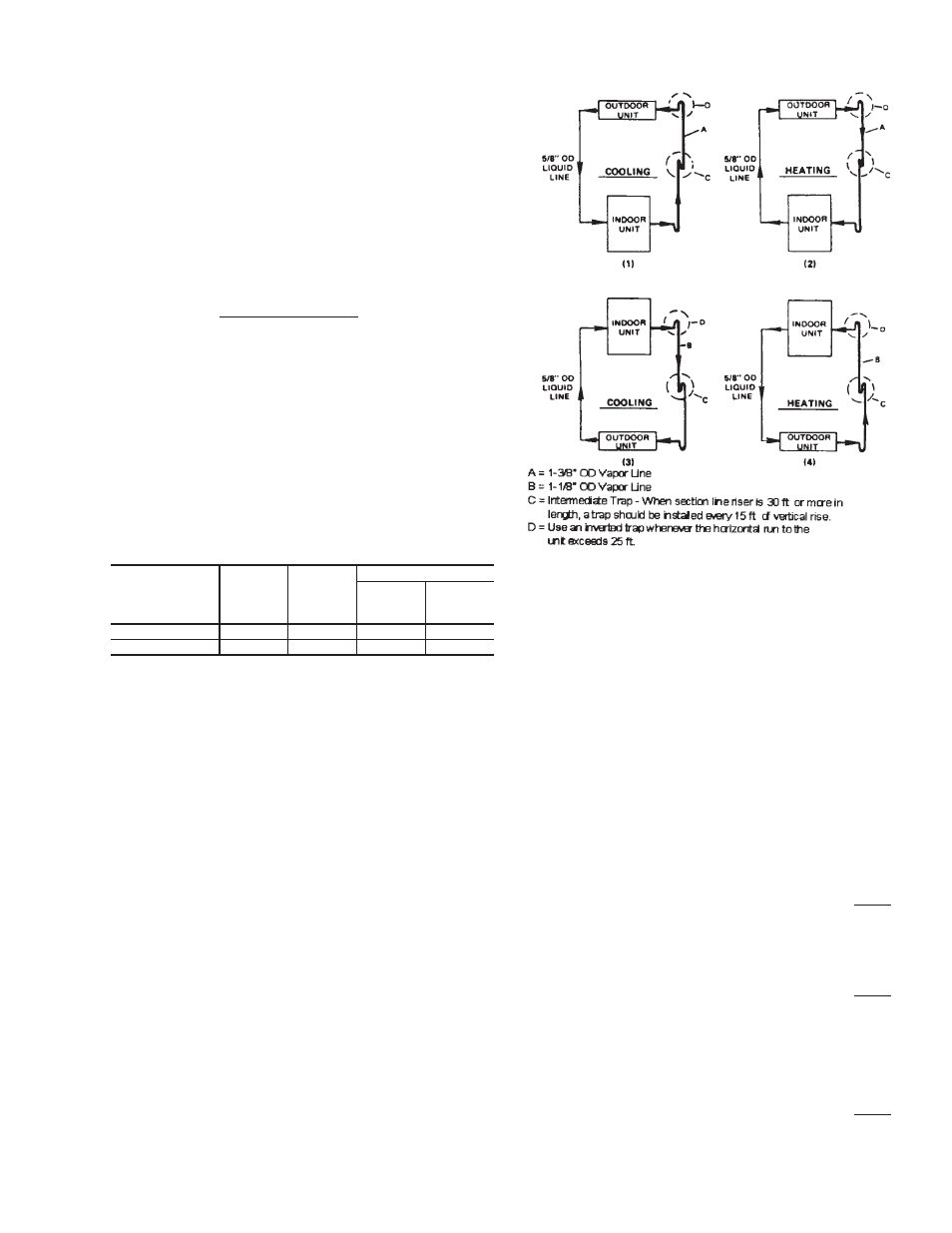

for a split heat pump system. Refer to Figure 5.

THE LIQUID LINE - The vertical rise should never exceed 50

feet because liquid refrigerant will lose 0.5 psi of static head for

each vertical foot.

The total pressure loss for a field-installed liquid line should

never exceed 40 psi because the liquid refrigerant could flash

before it reaches the expansion valve. This flashing will not

only cause erratic valve operation and poor system perform-

ance, but could also damage the expansion valve.

Total pressure loss includes the static head loss explained

above plus the friction losses due to the length of the line (Table

4) and number of fittings in the line.

When the indoor unit is above the outdoor unit, the friction loss

through the 1-1/8" OD vapor riser will be more of a limiting fac-

tor than the loss of static head in the liquid riser. See Example

#3 and #4 for the VAPOR LINE.

THE VAPOR LINE - A vapor line should not only be sized for a

friction loss of 3 psi (2°F) but also for the proper return of oil to

the compressor during both the cooling and heating cycles.

Friction loss should always be based on cooling operation be-

cause refrigerant flow rates will be greater during the cooling

cycle than during the heating cycle.

Oil return will be critical during:

1. The cooling cycle when the outdoor unit is above the indoor

unit (detail 1 of Figure 5).

2. The heating cycle when the indoor unit is above the outdoor

unit (detail 4 of Figure 5).

When the indoor unit is above the outdoor unit, the size of the

vapor riser must be reduced to 1-1/8" OD so that the velocity of

the refrigerant will be great enough to carry oil up the riser dur-

ing the heating cycle.

When 1-1/8" OD tubing must be used for the riser, the maxi-

mum length for the vapor line will be greatly reduced as shown

in the following examples.

EXAMPLES:

#1 - 7-1/2 Ton System

125 feet of 1-3/8" OD, type “L” copper tubing

(125 feet x 1.6 psi/100 feet) ...........................................2.0 psi

Fitting*....................................................................................0.4 psi

Vapor Line Pressure Drop = 2.4 psi

#2 - 10 Ton System

89 feet of 1-3/8" OD, type “L” copper tubing

(89 feet x 2.8 psi/100 feet) .............................................2.5 psi

Fitting*....................................................................................0.5 psi

Vapor Line Pressure Drop = 3.0 psi

#3 - 7-1/2 Ton System

51 feet of 1-1/8" OD, type “L” copper tubing (vertical)

(51 feet x 4.7 psi/100 feet) .............................................2.4 psi

6 feet of 1-3/8" OD, type “L” copper tubing (horizontal)

(6 feet x 1.6 psi/100 feet) ...............................................0.1 psi

Fitting*....................................................................................0.5 psi

Vapor Line Pressure Drop = 3.0 psi

#4 - 10 Ton System

29 feet of 1-1/8" OD, type “L” copper tubing (vertical)

Unitary Products Group

7

035-15410-002-B-0404

System

Model

Refrigerant

Flow Rate,

1

(Lbs/Min)

Type L

Copper

Tubing,

(In. OD)

Pressure Drop

3

Friction,

2

(PSI/100 Ft)

Vertical

Rise

(PSI/Ft)

EFB090/FEH090

22.5

5/8

3.5

0.5

EFB120/FEH120

30.0

5/8

5.8

0.5

1

Based on Refrigerant-22 at the nominal cooling capacity of the system, a liquid temperature

of 105°F and a vapor temperature of 40°F. Since refrigerant flow rates will be a little lower at

the nominal heating capacity of each system, liquid line friction loss should always be based

on cooling operation.

2

These friction losses do not include any allowance for fittings.

3

The total pressure drop of the liquid line for both friction and vertical rise must not exceed 40

PSI. If the pressure drop exceeds 40 PSI, the liquid refrigerant could flash before it reaches

the expansion valve. This flashing will not only cause erratic valve operation and poor system

performance, but could also damage the expansion valve.

TABLE 4

- LIQUID LINES

FIG. 5 - FIELD PIPING DIAGRAMS

(Cooling/Heating Refrigerant Flow)