York E2FB120 User Manual

Page 4

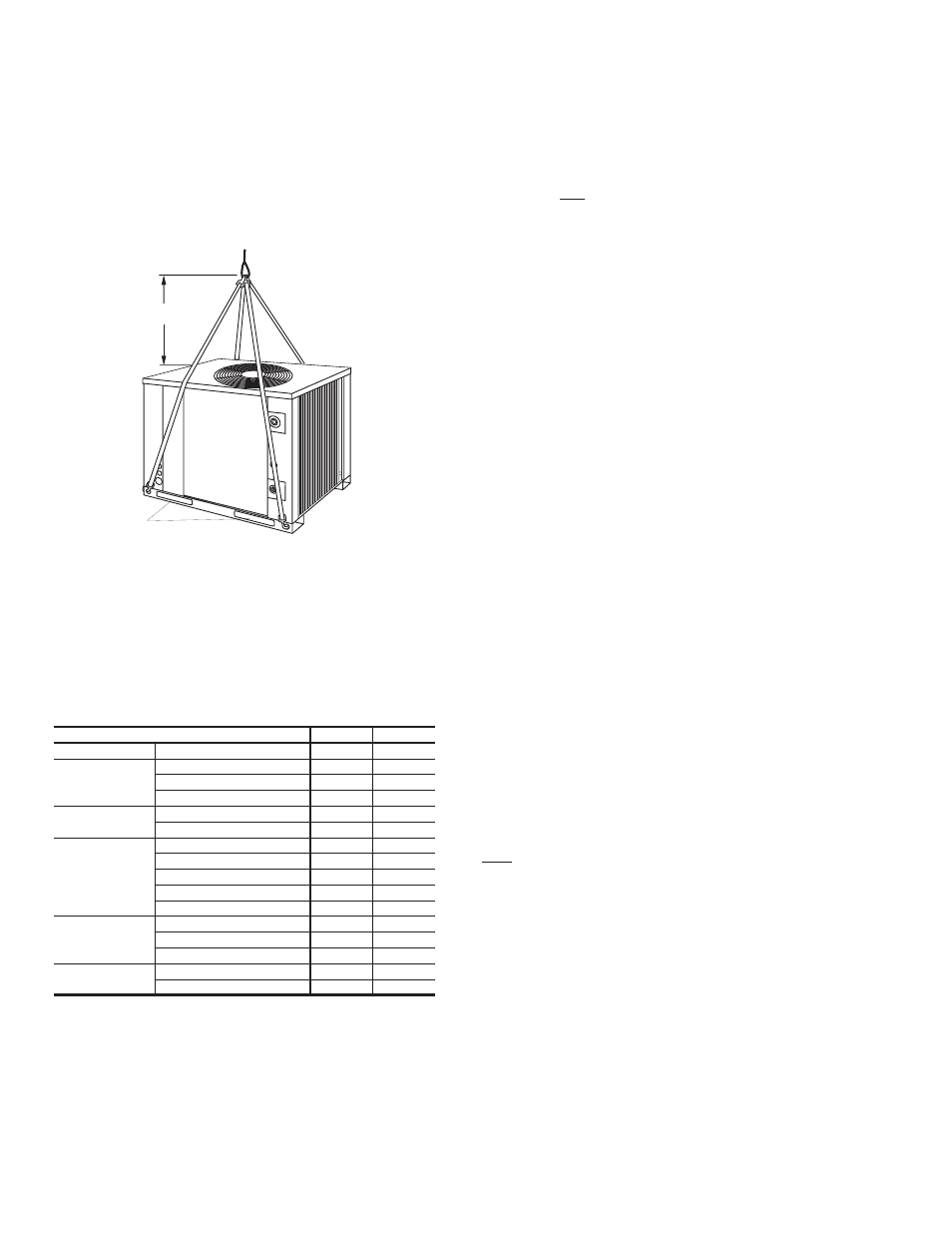

Units may also be moved or lifted with a fork-lift. Slotted open-

ings in the base rails are provided for this purpose. The 7-1/2

ton unit may be lifted from either the LH or RH side - under the

unit.

LENGTH OF FORKS MUST BE A MINIMUM OF 42" (for 7-1/2

ton units) and a MINIMUM OF 54" (for 10 ton units) when lifting

from either side.

Remove the nesting brackets from the four corners on top of

the unit. All screws that are removed to take these brackets off

must be replaced on the unit

CLEARANCES

All units require certain minimum clearances for proper opera-

tion and service. Refer to Figure 4 for these clearances.

WARNING: Do not permit overhanging structures or shrubs to

obstruct air discharge.

Additional height may be required for snow clearance if winter

operation is expected.

COMPRESSORS

Units are shippedwith compressormountingsfactory-adjusted

and ready for operation.

CAUTION: Do Not loosen compressor mounting bolts.

COMPRESSOR CRANKCASE HEATER

The compressor is equipped with a crankcase heater to pre-

vent refrigerant from mixing with crankcase oil during the

OFF cycle. The heaters will be energized when the compres-

sor is not running providing the unit disconnect switch is

closed.

CAUTION: Do not attempt to start the compressor without at

least eight hours of crankcase heat or compressor

damage will occur.

If a unit has just been installed or the unit disconnect switch has

been open for a long period of time, move the system switch on

the room thermostat to the “OFF” position before closing the

unit disconnect switch. Eight hours of crankcase heat are re-

quired to drive the liquid refrigerant out of the compressor bef-

ore the compressor can be started.

POWER AND CONTROL WIRING

Install electrical wiring in accordance with the latest National

Electrical Code (NFPA Standard No. 70) and/or local regula-

tions. The unit should be grounded in accordance with these

codes.

POWER WIRING

Check the voltage of the power supply against the data on the

unit nameplate. Check the size of the power wire, the discon-

nect switch and the fuses against the data on Table 3.

NOTE: Copper conductors must be installed between the dis-

connect switch and the unit.

Refer to Figure 4 for the location of the power wire access

opening through the front of the unit. This opening will require a

field-supplied conduit fitting.

The field-supplied disconnect switch must be suitable for an

outdoor location. Although it should be installed near the unit,

do NOT secure it to the unit cabinet.

Refer to Figure 3 for typical field wiring.

CONTROL WIRING

Refer to Figure 4 for the location of the control wire access

opening through the front of the unit.

Route the necessary low voltage control wires from terminal

block 1TB of the unit controlbox throughthis accessopeningto

the indoor unit and to the room thermostat. Refer to Figure 3 for

typical field wiring.

The room thermostat should be mounted about 5 feet above

the floor and located where it will be exposed to normal room

air circulation.Do not locate it on an outside wall, near a supply

air grill, or where it may be affected by sunlight and/or drafts.

Circulation of air to the thermostat should not be blocked by

curtains, drapes, furniture, partitions, etc.

4

Unitary Products Group

035-15410-002-B-0404

FIG. 2 - TYPICAL RIGGING

MODEL

EFB090

EFB120

Compressor

1

Rating, (Tons)

7-1/2

10

Fans

Quantity

1

2

Diameter, (In.)/No. Blades

24/3

24/3

Nominal CFM

4604

7600

Fan Motors

2

HP

3/4

1/2

RPM

1100

1100

Coil

Face Area, (Sq. Ft.)

18.75

24.00

Rows Deep x Rows High

2 x 30

2 x 36

Finned Length, (In.)

90

96

Tube (Copper) OD - inches

3/8

3/8

Fins (Aluminum) per inch

18

16

Refrigerant-22

(Lbs.)

Holding Charge

1.0

2.25

Operating Charge

3

14.3

21.4

Pumpdown Capacity

4

19.6

24.6

Unit Weight

(Lbs.)

Shipping

355

435

Operating

350

430

1

These compressors are fully hermetic.

2

These PSC motors are directly connected to the outdoor fans and have inherent protection,

ball bearings and a 48 frame. Rotation (when viewing the shaft end of the motor) - 090=CW,

120=CCW.

3

Includes outdoor unit and matched indoor blower unit, but no piping. Refer to Table 6 for re-

frigerant line charge.

4

Based on a 95°F ambient.

TABLE 2 - PHYSICAL DATA

5 F T . M I N .

FORK-LIFT

OPENINGS

7-1/2 TON UNIT SHOWN