035m00003- j354-en.pdf, Technical specification, Maintenance – York YOCC-YOHC 12-60 User Manual

Page 4

NORMAL FUNCTION OF THE AIR CONDITIONER

The following symptoms do not indicate air conditioner malfunction.

1. The system does not operate

• The system does not restart immediately

after the ON/OFF button is pressed.

If the OPERATION lamp lights, the system is

in normal condition.

The safety device operates to prevent overload of the system.

After 3 minutes, the system will turn on again automatically.

• The system does not restart immediately when

TEMPERATURE SETTING changed.

If the OPERATION lamp lights, the system is in normal condition.

If the timer light is flashing operation is being delayed by the safety

device. It does not restart immediately because the compressor

has been stopped and requested to start within the delay period.

A safety device operates to prevent overload of the system.

After 3 minutes, the system will turn on again automatically.

• The system does not start immediately after the power supply is turned on.

Wait one minute until the microcomputer is prepared for operation.

1.1 White mist comes out of a unit

• When humidity is high during cooling operation.

(In dusty locations or after construction work)

If the inside of an indoor unit is contaminated,

the temperature distribution inside a room may

become uneven. It is necessary to clean the inside

of the indoor unit. The unit should be cleaned by

a quali fied service person familiar with the unit.

• When the system is changed over to HEATING OPERATION

or after DEFROST OPERATION. Moisture generated on

the coil by the DEFROST becomes vapour and exists.

1.2 Noise of air conditioners

• A continuous flow “Shuh” sound is heard when the systems is in COOLING

or DEFROST OPERATION. This is the sound of refrigerant

gas flowing through both indoor and outdoor units.

• A “Shuh” sound which is heard at the start or

immediately after operation. It may also be heard

at the start or immediately after a DEFROST OPERATION.

This is the noise of refrigerant caused by the start and stop of the flow.

• A “Pishi-pishi” squeaking sound is heard when the system is in

operation or just after operation. Expansion and contraction of plastic

parts caused by temperature change makes this noise.

1.3 Dust from the units

• Dust may blow out from the unit when starting after long off cycles.

Dust absorbed by the unit blows out.

• The units give off odours. The unit absorbs the smell of rooms,

furniture, cigarettes, etc., and then emits them.

EMERGENCY OPERATION

• Units are equipped with a switch to run

emergency operation mode. Pushing the

emergency switch turns the unit on;

pushing it again turns if off (toggle action).

During emergency operation, the remote

controller cannot be used and the power

LED light will flash at intervals, while the

other LED lights will indicate the operation

of the Diagnostic Codes.

In Emergency Operation and cooling units

the temperature will be set at 24°C and the fan on Auto.

Heating units will switch to auto mode at a temperature set

point of 24°C and the fan will run on auto mode.

• After a power failure the unit restarts automatically in the same

mode as before the failure, when power is resumed.

TECHNICAL SPECIFICATION

TECHNICAL SPECIFICATION

■

Floor/Ceiling YOHC (YOKC-YOJC)R-410A 50Hz Rev.291106

PROTECTION FUNCTION

Auto Restart Function

• The unit will automatically restart after loss of the electrical power supply. When power is

restored; the unit operation will restart according to all parameters set before the loss of

power.

ANTI-ICE and ANTI-OVERHEAT

• This feature is used to prevent the indoor unit from freezing during cool or dry operation

and overheating in heat mode. During execution of anti-ice operation and anti-overheating,

the compressor will stop operating and the fan will continue to run until the coil temperature

reaches predetermined set points, at which time the unit will resume normal operation.

Low Voltage

• The feature is used to protect against any damage to the unit caused by fluctuation of voltage.

If voltage is lower than the lower limit for approximately 10 seconds or longer, compressor

operation will be temporarily stopped. Normal operation will resume when the voltage returns

above the set limit for a minimum of 10 seconds. If the time elapsed is less than 3 minutes

then the compressor start up will be delayed until 3 minutes has passed.

Filter Care and Filter Alarm

• Replace Air Purifying filter if fitted.

• The filters should be cleaned regularly, i.e, once a month, or more frequently depending on

conditions. The control is equipped with a filter alarm; After a certain numbers of hours of

operation, flashing lights will indicate that it is time to clean the filter. The alarm is reset by

pressing the filter button or the transmitter.

MAINTENANCE

The units are designed to operate for long periods of time with a minimum of maintenance.

However, the following operation must be performed regularly.

* This operation must be carried out by quali fied personnel only.

BEFORE MAINTENANCE

S Turn off the main breaker or disconnect the main power supply.

Notes

• Don’t spill water : There is a danger of electric shock.

• Don’t used petrol, paint thinner, benzene or polishing agents

: They may deform or scratch the unit.

CLEANING THE UNIT

Wipe the unit with a soft dry cloth only.

If the unit is very dirty, wipe it with a cloth soaked

in warm water (Not more than 40°C).

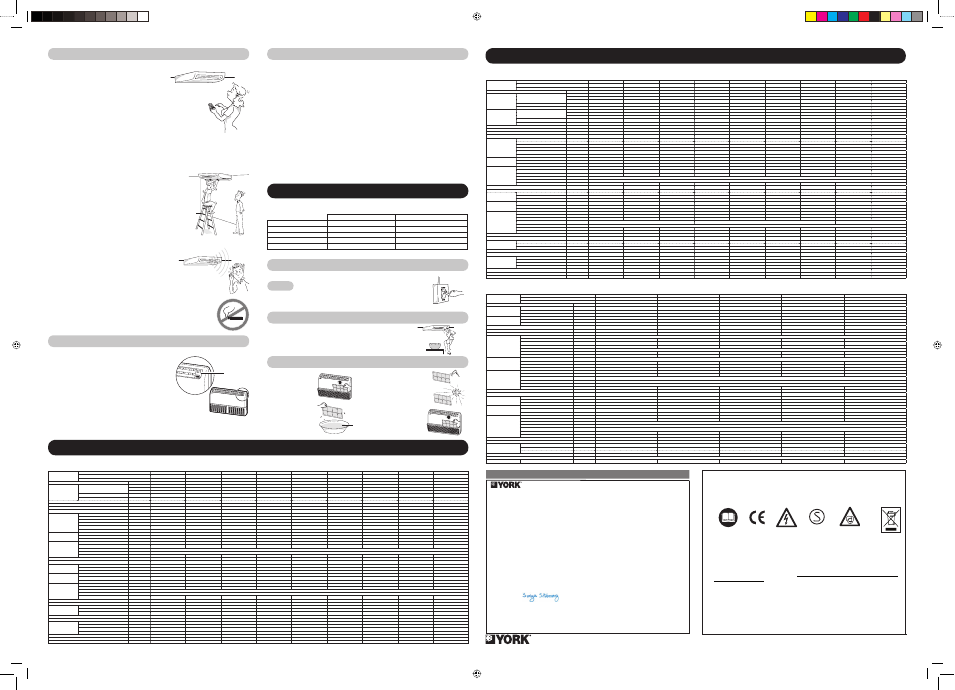

CLEANING THE AIR FILTER

1. Remove the air filter.

Open front grille

and pull fillter

outward front grille.

3. Drying

Drying the air filter by hair

drying or direct sunlight.

2. Cleaning

If the fillter is very dirty,

clean it with water

(approx 30°C).

4. Reinstall the air filter.

Approx 30 °C

EMERGENCY

OPERATION

Not more than

40°C

Remark: The above design and specifications are subject to change without prior notice for product improvement.

Floor/Ceiling YOCC (YOEC-YODC) COOLING R-410A 50Hz Rev.291106

Maintenance Operations

Recommended Frequency

Air filter

Clean

Every month or more often if necessary

Unit casing

Clean

Every month or more often if necessary

Drain pan and evacuation piping

Clean and check for obstructions

Each season before start up*

Indoor/outdoor coils

Clean

Each season before start up*

Compressor

No need

Model

Set

YOHC18DSBAAR

YOHC24DSBAAR

YOHC36DSBACR

YOHC48DSBACR

YOHC60DSBACR

Indoor

YOKC18DS-BAR

YOKC24DS-BAR

YOKC36DS-BCR

YOKC48DS-BCR

YOKC60DS-BCR

Outdoor

YOJC18DS-BAR

YOJC24DS-BAR

YOJC36DS-BCR

YOJC48DS-BCR

YOJC60DS-BCR

Power supply

V-Ph-Hz

220~240-1-50

220~240-1-50

380V~3~ 50Hz

380V~3~ 50Hz

380V~3~ 50Hz

Cooling

Capacity

Btu/h

18,000

24,000

36,000

48,000

60,000

Input

W

1,550

2,220

3,290

4,300

4,940

Rated current

A

6.8

9.25

8.77

11.47

11.47

Heating

Capacity

Btu/h

21,000

28,000

40,000

53,000

62,000

Input

W

1,680

2,250

3,160

4,170

4,880

Rated current

A

7.35

9.4

8.33

10.99

11.4

Max. input consumption

W

2,500

2,750

3,880

4,850

5,990

Max. current

A

10

11

10.17

12.98

15.69

Starting current

A

1.08

1.15

1.1

1.16

1.23

Compressor

Type

DC Inverter Rotary

DC Inverter Scroll

Input

W

1,650

1,650

3,665

3,665

3,665

Rated current (RLA)

A

8

8

7.8

7.8

7.8

Locked rotor Amp (LRA)

A

28

28

28

28

28

Protector

Thermal

Capacitor

µF

50

50

50

50

50

Refrigerant oil

ml

480

480

500

500

500

Indoor fan motor

Type

AC Motor

Input

W

110

110

134

89.5

59

Capacitor

µF

2.5

2.5

3.5

2.5

2.5

Speed (Hi/Me/Lo)

r/min

1,310/1,190/1,020

1,310/1,190/1,020

1,265/1,165/1,075

1,170/1,070/995

1,145*1,035*975

Indoor coil

Number of rows

3

3

3

3

3

Fin spacing

mm

1.8

1.8

1.8

1.8

1.8

Fin type

Hydrophilic aluminium

Tube outside dia.

mm

Ø9.52

Tube Material

Innergroove tube

Coil length × height × width

mm

828Ч254Ч66

828Ч254Ч66

905Ч203Ч66

1150Ч254Ч66

1150Ч254Ч66

Indoor air flow (Hi/Me/Lo)

m

3

/h

910/810/700

910/810/700

1,400/1,200/1,000

2,000/1,800/1,600

2,000/1,800/1,600

Indoor noise level (Hi/Me/Lo)

dB(A)

49.5/-/-

53/-/-

45/43/40

47/45/42

47/45/42

Indoor unit

Dimension (W*H*D)

mm

980Ч660Ч195

980Ч660Ч195

1,285Ч660Ч198

1,670Ч680Ч240

1,670Ч680Ч240

Packing (W*H*D)

mm

1,089Ч744Ч296

1,089Ч744Ч296

1,379Ч744Ч296

1,764Ч760Ч329

1,764Ч760Ч329

Net/Gross weight

kg

29/35

29/35

37/42

54/61

54/61

Outdoor fan motor

Input

W

129

150

307

150*2

150*2

Capacitor

µF

3

3

10

3.5*2

3.5*2

Speed

r/min

770

800

740

800

800

Outdoor coil

Number of rows

2

2

1

1

1

Fin spacing

mm

1.7

1.5

1.7

1.8

1.8

Fin type

Hydrophilic aluminium

Tube outside dia.

mm

Ø9.52

Tube Material

Innergroove tube

Coil length × height × width

mm

630Ч660Ч44

620Ч813Ч44

955Ч915Ч22

715Ч610Ч22

1,150Ч305Ч66

Number of circuits

4

2

8

4

4

Outdoor air flow

m

3

/h

2,400

3,000

5,000

6,000

6,000

Outdoor noise level

dB(A)

56

55

57

58

58

Outdoor unit

Dimension (W*H*D)

mm

840Ч677Ч310

894Ч860Ч302

990Ч960Ч340

940Ч1,245Ч340

940Ч1,245Ч340

Packing (W*H*D)

mm

965Ч770Ч395

1,043Ч915Ч395

1,120Ч1,015Ч435

1,058Ч1,300Ч435

1,058Ч1,300Ч435

Net/Gross weight

kg

62.5/66.5

72/76.5

106/111

117/126

112/127

Refrigerant R-410A

g

1,650

2,200

2,600

3,550

4,200

Throttle type

EXV&Capillary

Refrigerant piping

Liquid side/Gas side

mm

6.35/12.7

9.53/16

9.53/16

9.53/16

9.53/16

Model

Set

YOCC12FSA(B)AAR

YOCC18FSA(B)AAR

YOCC24FSA(B)AAR

YOCC30FSA(B)ACR

YOCC30FSA(B)AAR

YOCC36FSA(B)AAR

YOCC36FSA(B)ACR

YOCC48FSA(B)ACR

YOCC60FSA(B)ACR

Indoor unit

YOEC12FS-A(B)AR

YOEC18FS-A(B)AR

YOEC24FS-A(B)AR

YOEC30FS-A(B)CR

YOEC30FS-A(B)AR

YOEC36FS-A(B)AR

YOEC36FS-A(B)CR

YOEC48FS-A(B)CR

YOEC60FS-A(B)CR

Outdoor Unit

YODC12FS-A(B)AR

YODC18FS-A(B)AR

YODC24FS-A(B)AR

YODC30FS-A(B)CR

YODC30FS-A(B)AR

YODC36FS-A(B)AR

YODC36FS-A(B)CR

YODC48FS-A(B)CR

YODC60FS-A(B)CR

Power supply

Ph-V-Hz

1,220-240V,50Hz

1,220-240V,50Hz

1,220-240V,50Hz

3,380V,50Hz

1,220-240V,50Hz

1,220-240V,50Hz

3,380V,50Hz

3,380V,50Hz

3,380V,50Hz

Cooling

Capacity

Btu/h

12,000

18,000

24,000

30,000

30,000

36,000

36,000

48,000

60,000

kW

3.5

5.4

7.1

9.2

9.2

10.5

10.5

14

17

kcal/h

3,024

4,536

6,048

7,560

7,560

9,072

9,072

12,096

15,120

Input

W

1,200

1,900

2,600

3,450

3,450

3,800

3,800

4,900

5,800

Rated current

A

5.3

8.5

12.1

6.4

16.4

19.2

6.4

8.2

9.8

Moisture Removal

L/h

1.2

1.8

2.4

3

3

3.6

3.8

4.8

6

Max. input consumption

W

1,400

2,600

3,300

5,200

5,200

5,200

5,200

6,100

7,200

Max. current

A

7.2

13

16.5

8.8

25

26.3

8.8

10.3

12.2

Starting current

A

26

36.8

61

97

97

97

61

66

67

Compressor

Type

ROTARY

ROTARY

ROTARY

SCROLL

SCROLL

SCROLL

SCROLL

SCROLL

SCROLL

Input

W

1,145

1,870

2,430

3,650

3,650

3,650

3,650

4,750

5,750

Rated current (RLA)

A

5.3

8.75

11.4

6.58

17.65

17.65

6.58

8.22

9.77

Locked rotor Amp (LRA)

A

26

36.8

61

61

97

97

61

66

67

Thermal protector

Inner

Inner

Inner

Inner

Inner

Inner

Inner

Inner

Inner

Capacitor

µF

35/370µF/V

50/370µF/V

50/400µF/V

/

60µF/440V

60µF/440V

/

/

/

Indoor fan motor

Input

W

104/98

110/104/98

110/104/98

142/134/132

142/134/132

142/134/132

142/134/132

118/108/101

118/108/101

Capacitor

µF

1.5µF/450V

2.5µF/450V

2.5µF/450V

3.5µF/450V

3.5µF/450V

3.5µF/450V

3.5µF/450V

2.5µF/450V

2.5µF/450V

Speed (Hi/Mid/Low)

r/min

1,190/1,000/890

1,280/1,190/1,000

1,280/1,190/1,000

1,310/1,200/1,000

1,310/1,200/1,000

1,310/1,200/1,000

1,310/1,200/1,000

820/695/620

820/695/620

Indoor coil

Number of rows

2

3

3

3

3

3

3

3

3

Fin spacing

mm

1.7

1.7

1.7

1.7

1.7

1.7

1.7

1.7

1.7

Fin type

Hydrophilic aluminum

Tube outside dia.and type

mm

Ø9.53 innergroove tube

Coil length × height × width

mm

804Ч254Ч44

804Ч254Ч66

804Ч254Ч66

905Ч203Ч66

905Ч203Ч66

905Ч203Ч66

905Ч203Ч66

1,150Ч254Ч66

1,150Ч254Ч66

Indoor air flow (Hi/Mid/Low)

m

3

/h

600/480/400

800/600/500

1,000/900/700

1,200/1,000/800

1,400/1,200/1,000

1,400/1,200/1,000

1,400/1,200/1,000

2,000/1,800/1,600

2,000/1,800/1,600

Indoor noise level (Hi/Mid/Low)

dB(A)

43/41/38

43/41/38

45/43/40

45/43/40

45/43/40

45/43/40

45/43/40

47/45/42

47/45/42

Indoor unit

Dimension (W*H*D)

mm

995Ч660Ч198

995Ч660Ч198

995Ч660Ч198

1,285Ч660Ч198

1,285Ч660Ч198

1,285Ч660Ч198

1,285Ч660Ч198

1,670Ч680Ч240

1,670Ч680Ч240

Packing (W*H*D)

mm

1,075Ч744Ч278

1,075Ч744Ч278

1,075Ч744Ч278

1,365Ч744Ч278

1,365Ч744Ч278

1,365Ч744Ч278

1,365Ч744Ч278

1,764Ч760Ч329

1,764Ч760Ч329

Net/Gross weight

kg

30/37

30/37

30/37

34/42

34/42

34/42

34/42

52/62

52/62

Outdoor fan

motor

Input

W

56

130

130

307

307

307

307

138+156

138+156

Capacitor

µF

2.5µF/450V

2.5µF/450V

3µF/450V

10µF/450V

10µF/450V

10µF/450V

10µF/450V

3.5×2µF/450V

3.5×2µF/450V

Speed

r/min

800

750

800

740

740

740

740

800

800

Outdoor coil

Number of rows

2

2

2

2

2

2

2

2

2

Fin spacing

mm

1.4

1.7

1.5

1.7

1.7

1.7

1.7

1.8

1.8

Fin type

Unhydrophilic aluminum

Tube outside dia. and type

mm

Ø9.53, Innergroove tube

Coil length × height × width

mm

651Ч559Ч44

775Ч660Ч44

850Ч810Ч44

955Ч915Ч44

955Ч915Ч44

955Ч915Ч44

955Ч915Ч44

715Ч1,220Ч44

715Ч1,220Ч44

Outdoor air flow

m

3

/h

2,100

2,400

3,000

5,000

5,000

5,000

5,000

6,000

6,000

Outdoor noise level

dB(A)

43

48

55

57

57

57

57

58

58

Outdoor unit

Dimension (W*H*D)

mm

760Ч590Ч285

845Ч695Ч335

895Ч860Ч330

990Ч960Ч360

990Ч960Ч360

990Ч960Ч360

990Ч960Ч360

940Ч1,245Ч340

940Ч1,245Ч340

Packing (W*H*D)

mm

887Ч655Ч355

970Ч770Ч395

1,043Ч915Ч395

1,120Ч1,090Ч435

1,120Ч1,090Ч435

1,120Ч1,090Ч435

1,120Ч1,090Ч435

1,058Ч1,380Ч435

1,058Ч1,380Ч435

Net/Gross weight

kg

44/48

57/62

68/70

90/102

90/102

90/102

90/102

112/127

112/127

Refrigerant type/Quantity

g

R-410A/1,100

R-410A/2,000

R-410A/2,600

R-410A/3,000

R-410A/3,000

R-410A/3,000

R-410A/3,000

R-410A/3,700

R-410A/3,900

Design pressure (high side/low side)

MPa

4.2/2.5

4.2/2.5

4.2/2.5

4.2/2.5

4.2/2.5

4.2/2.5

4.2/2.5

4.2/2.5

4.2/2.5

Refrigerant

piping

Liquid side

mm (inch)

6.35 (1/4)

6.35 (1/4)

9.53 (3/8)

12.7 (1/2)

12.7 (1/2)

12.7 (1/2)

12.7 (1/2)

12.7 (1/2)

12.7 (1/2)

Gas side

mm (inch)

12.7 (1/2)

12.7 (1/2)

16 (5/8)

19 (3/4)

19 (3/4)

19 (3/4)

19 (3/4)

19 (3/4)

19 (3/4)

Max. pipe length

m

25

25

30

30

30

30

30

50

50

Max. difference in level

m

15

15

15

20

20

20

20

30

30

Operation temp

ºC

17~30

17~30

17~30

17~30

17~30

17~30

17~30

17~30

17~30

Ambient temp

ºC

18~45

18~45

18~45

18~45

18~45

18~45

18~45

18~45

18~45

Qty’per 20’& 40’Fcl

Pieces

63/138/155

49/104/126

44/94/101

27/55/62

27/55/62

27/55/62

27/55/62

25/50/54

25/50/54

Model

Set

YOHC12FSA(B)AAR

YOHC18FSA(B)AAR

YOHC24FSA(B)AAR

YOHC30FSA(B)ACR

YOHC30FSA(B)AAR

YOHC36FSA(B)AAR

YOHC36FSA(B)ACR

YOHC48FSA(B)ACR

YOHC60FSA(B)ACR

Indoor unit

YOKC12FS-A(B)AR

YOKC18FS-A(B)AR

YOKC24FS-A(B)AR

YOKC30FS-A(B)CR

YOKC30FS-A(B)AR

YOKC36FS-A(B)AR

YOKC36FS-A(B)CR

YOKC48FS-A(B)CR

YOKC60FS-A(B)CR

Outdoor Unit

YOJC12FS-A(B)AR

YOJC18FS-A(B)AR

YOJC24FS-A(B)AR

YOJC30FS-A(B)CR

YOJC30FS-A(B)AR

YOJC36FS-A(B)AR

YOJC36FS-A(B)CR

YOJC48FS-A(B)CR

YOJC60FS-A(B)CR

Power supply

Ph-V-Hz

1,220-240V, 50Hz

1,220-240V, 50Hz

1,220-240V, 50Hz

3,380V, 50Hz

1,220-240V, 50Hz

1,220-240V, 50Hz

3,380V, 50Hz

3,380V, 50Hz

3,380V, 50Hz

Cooling

Capacity

Btu/h

12,000

18,000

24,000

30,000

30,000

36,000

36,000

48,000

60,000

kW

3.5

5.4

7.1

9.2

9.2

10.5

10.5

14

17

kcal/h

3,024

4,536

6,048

7,560

7,560

9,072

9,072

12,096

15,120

Input

W

1,200

1,900

2,700

3,750

3,750

3,750

3,750

4,700

6,000

Rated current

A

6

8.5

12

6.3

16.3

16.3

6.6

8.2

9.8

Heating

Capacity

Btu/h

13,000

20,500

27,300

32,000

32,000

39,000

39,000

52,000

68,000

kW

3.8

6

8

9.4

9.4

11.4

11.4

15.2

20

kcal/h

3,276

5,166

6,880

8,064

8,064

9,828

9,828

13,104

17,136

Input

W

1,130

1,850

2,800

3,500

3,500

3,500

3,700

4,900

6,000

Rated current

A

5

8

12.5

5.2

15.2

15.2

6.5

8.6

9.8

Moisture Removal

L/h

1.2

1.8

2.4

3

3

3.6

3.8

4.8

6

Max. input consumption

W

1,500

2,400

3,300

4,620

4,620

4,620

4,400

5,870

7,500

Max. current

A

7

11.5

14.5

7.1

21

21

8

10.7

12.8

Starting current

A

26

36.8

61

61

97

97

61

66

67

Compressor

Type

ROTARY

ROTARY

ROTARY

SCROLL

SCROLL

SCROLL

SCROLL

SCROLL

SCROLL

Input

W

1,145

1,870

2,430

3,650

3,650

3,650

3,650

4,750

5,750

Rated current (RLA)

A

5.3

8.75

11.4

6.58

17.65

17.65

6.58

8.22

9.77

Locked rotor Amp (LRA)

A

26

36.8

61

61

97

97

61

66

67

Thermal protector

Inner

Inner

Inner

Inner

Inner

Inner

Inner

Inner

Inner

Capacitor

µF

35/370µF/V

50/370µF/V

50/400µF/V

/

60µF/440V

60µF/440V

/

/

/

Indoor fan motor

Input

W

104/98

110/104/98

110/104/98

142/134/132

142/134/132

142/134/132

142/134/132

118/108/101

118/108/101

Capacitor

µF

1.5µF/450V

2.5µF/450V

2.5µF/450V

3.5µF/450V

3.5µF/450V

3.5µF/450V

3.5µF/450V

2.5µF/450V

2.5µF/450V

Speed (Hi/Med/Low)

r/min

1,190/1,000/890

1,280/1,190/1,000

1,280/1,190/1,000

1,310/1,200/1,000

1,310/1,200/1,000

1,310/1,200/1,000

1,310/1,200/1,000

820/695/620

820/695/620

Indoor coil

Number of rows

2

3

3

3

3

3

3

3

3

Tube pitch(a) × row pitch(b)

mm

25.4Ч22

25.4Ч22

25.4Ч22

25.4Ч22

25.4Ч22

25.4Ч22

25.4Ч22

25.4Ч22

25.4Ч22

Fin spacing

mm

1.7

1.7

1.7

1.7

1.7

1.7

1.7

1.7

1.7

Fin type

Hydrophilic aluminum

Tube outside dia. and type

mm

Ø9.53 innergroove tube

Coil length × height × width

mm

804Ч254Ч44

804Ч254Ч66

804Ч254Ч66

905Ч203Ч66

905Ч203Ч66

905Ч203Ч66

905Ч203Ч66

1,150Ч254Ч66

1,150Ч254Ч66

Indoor air flow (Hi/Mid/Low)

m

3

/h

600/480/400

800/600/500

1,000/900/700

1,200/1,000/800

1,400/1,200/1,000

1,400/1,200/1,000

1,400/1,200/1,000

2,000/1,800/1,600

2,000/1,800/1,600

Indoor noise level (Hi/Mid/Lo)

dB(A)

43/41/38

43/41/38

45/43/40

45/43/40

45/43/40

45/43/40

45/43/40

47/45/42

47/45/42

Indoor unit

Dimension (W*H*D)

mm

995Ч660Ч198

995Ч660Ч198

995Ч660Ч198

1,285Ч660Ч198

1,285Ч660Ч198

1,285Ч660Ч198

1,285Ч660Ч198

1,670Ч680Ч240

1,670Ч680Ч240

Packing (W*H*D)

mm

1,075Ч744Ч278

1,075Ч744Ч278

1,075Ч744Ч278

1,365Ч744Ч278

1,365Ч744Ч278

1,365Ч744Ч278

1,365Ч744Ч278

1,764Ч760Ч329

1,764Ч760Ч329

Net/Gross weight

kg

29/35

30/37

30/37

34/42

34/42

34/42

34/42

52/62

52/62

Outdoor fan

motor

Input

W

56

130

130

307

307

307

307

138+156

138+156

Capacitor

µF

2.5µF/450V

2.5µF/450V

3µF/450V

10µF/450V

10µF/450V

10µF/450V

10µF/450V

3.5×2µF/450V

3.5×2µF/450V

Speed

r/min

800

750

800

740

740

740

740

800

800

Outdoor coil

Number of rows

2

2

2

2

2

2

2

2

2

Tube pitch(a) × row pitch(b)

mm

25.4Ч22

25.4Ч22

25.4Ч22

25.4Ч22

25.4Ч22

25.4Ч22

25.4Ч22

25.4Ч22

25.4Ч22

Fin spacing

mm

1.4

1.7

1.5

1.7

1.7

1.7

1.7

1.8

1.8

Fin type

Hydrophilic aluminum

Unhydrophilic aluminium

Hydrophilic aluminum

Tube outside dia. and type

mm

Ø9.53x0.35,Innergroove tube

Coil length × height × width

mm

651Ч559Ч44

775Ч660Ч44

850Ч810Ч44

955Ч915Ч44

955Ч915Ч44

955Ч915Ч44

955Ч915Ч44

715Ч1220Ч44

715Ч1220Ч44

Number of circuits

2

3

4

8

8

8

8

4

4

Outdoor air flow

m

3

/h

2,100

2,400

3,000

5,000

5,000

5,000

5,000

6,000

6,000

Outdoor noise level

dB(A)

43

48

55

57

57

57

57

58

58

Outdoor unit

Dimension (W*H*D)

mm

760Ч590Ч285

845Ч695Ч335

895Ч860Ч330

990Ч960Ч360

990Ч960Ч360

990Ч960Ч360

990Ч960Ч360

940Ч1,245Ч340

940Ч1,245Ч340

Packing (W*H*D)

mm

887Ч655Ч355

970Ч770Ч395

1,043Ч915Ч395

1,120Ч1,090Ч435

1,120Ч1,090Ч435

1,120Ч1,090Ч435

1,120Ч1,090Ч435

1,058Ч1,380Ч435

1,058Ч1,380Ч435

Net/Gross weight

kg

44/48

57/62

68/70

90/102

90/102

90/102

90/102

112/127

112/127

Refrigerant type/Quantity

g

R-410A/1,120

R-410A/2,050

R-410A/2,600

R-410A/3,100

R-410A/3,450

R-410A/3,450

R-410A/3,100

R-410A/4,000

R-410A/4,200

Design pressure (high side/low side)

MPa

4.2/2.5

4.2/2.5

4.2/2.5

4.2/2.5

4.2/2.5

4.2/2.5

4.2/2.5

4.2/2.5

4.2/2.5

Refrigerant

piping

Liquid side

mm (inch)

6.35 (1/4)

6.35 (1/4)

9.53 (3/8)

12.7 (1/2)

12.7 (1/2)

12.7 (1/2)

12.7 (1/2)

12.7 (1/2)

12.7 (1/2)

Gas side

mm (inch)

12.7 (1/2)

12.7 (1/2)

16 (5/8)

19 (3/4)

19 (3/4)

19 (3/4)

19 (3/4)

19 (3/4)

19 (3/4)

Max. pipe length

m

25

25

30

30

30

30

30

50

50

Max. difference in level

m

15

15

15

20

20

20

20

30

30

Operation temp

ºC

17~30

17~30

17~30

17~30

17~30

17~30

17~30

17~30

17~30

Ambient temp

ºC

-7~45

-7~45

-7~45

-7~45

-7~45

-7~45

-7~45

-7~45

-7~45

Qty’per 20’& 40’Fcl

Pieces

63/138/155

49/104/126

44/94/101

27/55/62

27/55/62

27/55/62

27/55/62

25/50/54

25/50/54

■ Floor/Ceiling DC Inverter “YOHC” R-410A, 50Hz

J354-EN.indd 4

J354-EN.indd 4

4/25/07 5:03:18 PM

4/25/07 5:03:18 PM

York Industrial Thailand

49/40 Moo5, Tambon Tungsukla, Sriracha, Chonburi 20230, Thailand.

Tel. +6638 493400 Fax. +6638 493423- 424

Ref No.: 07GMSPG0529DC005-0

Type of Equipment:

Brand Name:

Type Designation: YOCC-YOHC 12/18/24/30/36/48/60 FS

YOHC 18/24/36/48/60 DS

Application of Council: Low Voltage Directive 73/23/EEC, EMC Directive

89/336/EEC, CE Marking

Directive 93/68/EEC and Machinery Directive 98/37/EEC.

The equipments above follow harmonized standards have been applied:

EN 60335-1:1994+A11:1995+A1, A12:1996+A 13, A14:1998+A15, A2:2000+A16:2001

EN 60335-2-40:1997+A1:2000

EN55014-1:2000+A1+A2

EN55014-2:1994+A1

EN61000-3-2:2000

EN61000-3-3:1995+A1

EN61000-3-11:2000

Authorized Representative:

_________________________

Suriya Sittidamrong

Senior Technical Support Engineer

DE - COMMISSIONING DISMANTLING & DISPOSAL

This product contains refrigerant under pressure, rotating parts, and electrical

connections which may be a danger and cause injury!

All work must only be carried out by competent persons using suitable protective

clothing and safety precautions.

1.

Isolate all sources of electrical supply to the unit including any control system supplies

switched by the unit. Ensure that all points of electrical and gas isolation are secured in the

OFF position. The supply cables and gas pipework may then be disconnected and removed.

For points of connection refer to unit installation instructions.

2. Remove all refrigerant from each system of the unit into a suitable container using a

refrigerant reclaim or recovery unit. This refrigerant may then be reused, if appropriate, or

returned to the manufacturer for disposal

Under No circumstances should refrigerant be

vented to atmosphere. Where appropriate, drain the refrigerant oil from each system into a

suitable container and dispose of according to local laws and regulations governing disposal

of oily wastes.

3. Packaged unit can generally be removed in one piece after disconnection as above. Any

fixing down bolts should be removed and then unit lifted from position using the points

provided and equipment of adequate lifting capacity. Reference MUST be made to the unit

installation instructions for unit weight and correct methods of lifting. Note that any residual

or spilt refrigerant oil should be mopped up and disposed of as described above.

4. After removal from position the unit parts may be disposed of according to local laws and

regulations.

Read the Manual

Unit is remotely controlled and

may start without warning

Risk of electric shock

DECLARATION OF CONFORMITY

Date: May 29, 2007

DECLARATION OF CONFORMITY

YORK

Air Conditioners