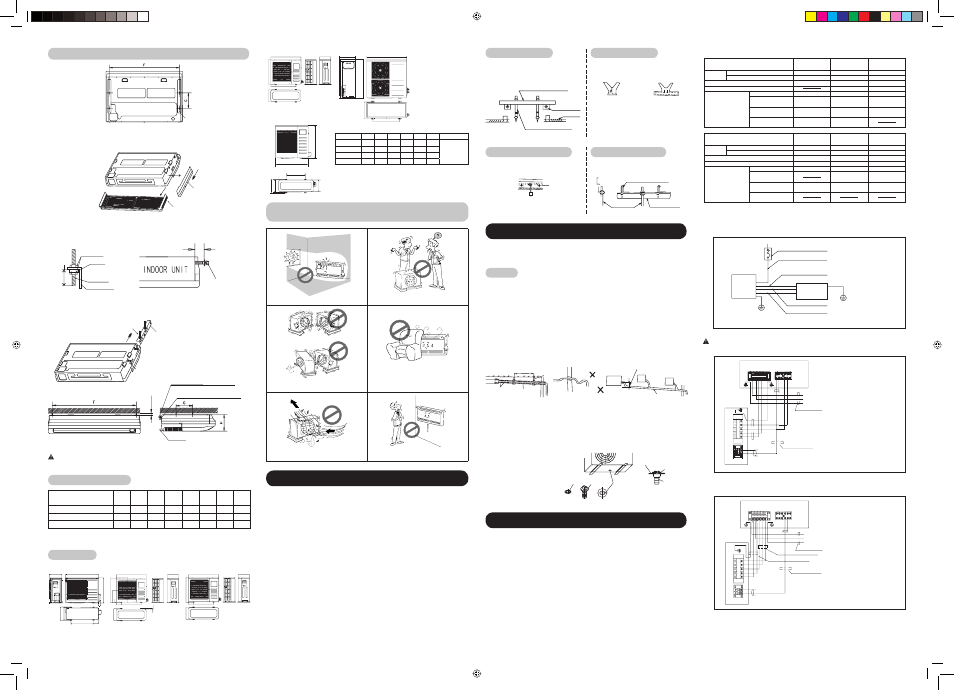

White (t3) black (e), Indoor unit installation, Connect the drain pipe – York YOCC-YOHC 12-60 User Manual

Page 2: Wiring

• The drain pipe of indoor unit must be heat insulated, or it will condense dew,

as well as the connections of the indoor unit.

• Hard PVC binder must be used for pipe connection, and make sure there is no

leakage.

• With the connection part to the indoor unit, please be noted not to impose

pressure on the side of indoor unit pipes.

• When the declivity of the drain pipe downwards is over 1/100, there should not

be any winding.

• The total length of the drain pipe when pulled out traversely shall not exceed

20m, when the pipe is over long, a prop stand must be installed to prevent

winding.

• Refer

to

the

fi gures on the right for the installation of the pipes.

INSTALLATION IN THE FOLLOWING PLACES

MAY RESULT IN TROUBLE

INDOOR UNIT INSTALLATION

Installing Ø10 hanging screw bolts. (4 bolts)

• Please refer to the following fi gure for the distance measurement between the

screw bolts.

• Please install with Ø10 hanging screw bolts.

• The handling to the ceiling varies from the constructions, consult the construction

personnels for the specifi c procedures.

1. The size of the ceiling to be handled ... ... do keep the ceiling fl at. Consolidate

the roof beam for possible vibration.

2. Cut off the roof beam.

3. Strengthen the place cut off, and consolidate the roof beam.

• Carry out the pipe and line operation in the ceiling after fi nishing the installation

of the main body. While choosing where to start the operation, determine the

direction of the pipes to be drawn out. Especially in case there is a ceiling, position

the refrigerant pipes, drain pipes, indoor & outdoor lines to the connection places

before hanging up the machine.

• The installation of hanging screw bolts.

Installation of the indoor unit in direct sun light.

Installation in the unit in wrong direction.

Installation of outdoor units too close or,

blowing discharged air into each other.

Installation of the indoor unit in a place where

there is an obstacle near the air inlet or outlet.

Installation of the outdoor unit in a place

exposed regularly to a strong wind.

> 30 cm

Installation of the indoor unit at too high > 30 cm

a position.

CEILING INSTALLATION

1. Remove the side board and the grille. (Refer to Chart 8)

(For models 48000 and 60000 Btu/h, do not remove the grille.)

2. Locate the hanging arm on the hanging screw bolt. (Refer to Chart 9)

Prepare the mounting bolts on the unit. (Refer to Chart 10)

3. Hang the unit on the hanging arm by sliding backward. Securely tighten the

mounting bolts on both sides. (Refer to Chart 9)

Chart 7

Chart 8

20

25mm

8

13mm

>20mm

Hanging arm

Hanging

screw bolt

Mounting bolt

D. Connecting point of refrigerant pipe

(D. gas side)

E. Connecting point of refrigerant pipe

(E. Liquid side)

Drain point

Chart 11

Chart 10

Screw nut

Washer

Hanging

screw bolt

Hanging arm

Mounting bolt (max. 40 mm)

Side board

Grille

Hanging arm

ATTENTION: The fi gures above are based on model with 18000 Btu/h as rated

capacity, which may differ from the unit you purchased.

The dimension of the unit

Capacity

(Btu/h)

A

B

C

D

E

F

G

H

12000-24000 Btu/h

990

660

206

505

506

907

200

203

36000 Btu/h

1280

660

206

795

506

1195

200

203

48000-60000 Btu/h

1670

680

244

1070

450

1542

200

240

• Note: The dimension of 12000 Btu/h and 24000 Btu/h are the same

The dimension of 48000 Btu/h and 60000 Btu/h are the same

Chart 17

The base pan hole

of outdoor unit

The base pan

hole of outdoor

Drain elbow

Seal

Seal

Drain elbow

Chart 9

285

750

845

590

695

860

351.2

135

235

125

335

330

530

110

62

315

290

301.5

141.5

560.1

163

590

313

895

300

■ YODC-YOJC 12

■ YODC-YOJC 18

■ YODC-YOJC 24

Outdoor unit

360

960

990

336.4

400

1245

360

940

650

181.4

624

■ YODC-YOJC 30-36

■ YODC-YOJC 48-60

B

C

E

D

A

H

■ DC Inverter R-410A

MODEL

A

B

C

D

E

H

REMARK

18

840 550 335 360 310 677

R-410A

24

894 590 333 355 302 860

36

990 624 366 396 340 960

48

940 600 376 400 340 1245

Wooden construction

New concrete bricks

For Original concrete bricks

Steel roof beam structre

Put the square timber traversely over

the roof beam, then install the hanging

screw bolts. (Refer to Chart 1)

Inlaying or embedding the screw bolts.

(Refer to Chart 2)

Use embedding screw bolt. (Refer to

Chart 3)

Install and use directly the supporting

angle steel. (Refer to chart 4)

Timber over the beam

Roof beam

Ceiling

Hanging screw bolts

Chart 1

Chart 2

(Blade shape insertion)

(Slide insertion)

Steel bar

Embedding screw bolt

(Pipe hanging and embedding

screw bolt)

Chart 3

Hanging screw bolt

Supporting

angle steel

Hanging bolts

Chart 4

CONNECT THE DRAIN PIPE

1. Install indoor unit drain pipe

The outlet has PTI screw thread, Please use sealing materials and pipe sheath

(fi tting) when connecting PVC pipes.

Cautions

2. Drainage test

• Check whether the drainpipe is unhindered

• New built house should have this test done before paving the ceiling.

3. Drain Elbow Installation

Fit the seal into the drain elbow, then insert the drain elbow into the base pan

hole of outdoor unit, rotate 90° to securely assemble them. Connect the drain

elbow with an extension

drain hose (Locally purchased),

in case of the condensate

draining off the outdoor unit

during the heating mode.

(Refer to Chart 17)

1.5m~2m

Insulating

material

Downward

declivity lower

than 1/100

Bend

S shape

Put as deep as possible

(about 10cm)

Downward declivity

lower than 1/100

VP30

WIRING

■

Attaching wiring

1. The air conditioner should use separate power supply with rated voltage

2. The external power supply to the air conditioner should have ground wiring,

which is linked to the ground wiring of the indoor and outdoor unit.

3. The wiring work should be done by qualifi ed persons according to circuit

drawing.

4. A leakage protector should be installed according to the National Standard

concerning electrical appliance.

5. Be sure to locate the power wiring and the signal wring well to avoid cross-

disturbance and their contact with connecting pipe or stop valve body.

6. The wiring attached to this air conditioner is 10m long. Be sure to prolong it

with wiring of the same type and proper length if necessary. Generally, do not

twist two wiring together unless the joint is soldered well and covered with

insulator tape.

7. Do not turn on the power until you have checked carefully after wiring.

TYPE

12000~18000 Btu/h

(Cooling&Heating)

24000-36000 Btu/h

(Cooling&Heating)

36000-60000 Btu/h

(Cooling&Heating)

POWER

PHASE

1-PHASE

1-PHASE

3-PHASE

FREQUENCY AND VOLT

220-240V~, 50Hz

220-240V~, 50Hz

380V 3N~, 50Hz

CIRCUIT BREAKER/FUSE (A)

20/16

40/25

40/20

INDOOR UNIT POWER WIRING (mm

2

)

3x2.5

5x2.5

INDOOR/OUTDOOR

CONNECTING

WIRING

(mm

2

)

GROUND WIRING

2.0

2.5

2.5

OUTDOOR UNIT

POWER WIRING

3x2.5

3x2.5

5x2.5

STRONG ELECTRIC

SIGNAL

5x2.0

(3x2.0)

3x2.0

(2x2.0)

3x2.0

(2x2.0)

WEAK ELECTRIC

SIGNAL

1-core sheild wire

1x0.5mm

2

2-core sheild wire

2x0.5mm

2

TYPE

12000~18000 Btu/h

(Cooling Only)

24000-36000 Btu/h

(Cooling Only)

36000-60000 Btu/h

(Cooling Only)

POWER

PHASE

1-PHASE

1-PHASE

3-PHASE

FREQUENCY AND VOLT

220-240V~, 50Hz

220-240V~, 50Hz

380V 3N~, 50Hz

CIRCUIT BREAKER/FUSE (A)

40/25

40/20

40/25

INDOOR UNIT POWER WIRING (mm

2

)

3x2.5

3x2.5

5x2.5

INDOOR/OUTDOOR

CONNECTING

WIRING

(mm

2

)

GROUND WIRING

2.0

2.0

2.0

OUTDOOR UNIT

POWER WIRING

3x2.0

5x2.0

STRONG ELECTRIC

SIGNAL

3x2.0

1x2.0

1x2.0

WEAK ELECTRIC

SIGNAL

■

Wiring Chart

Installing wiring chart, refer to link circuit chart for details.

CAUTION: When wiring, please choose the corresponding chart, or it may

cause damage.

Power supply

Switch/Fuse

(Available locally)

Power wiring (indoor)

Power linking wiring (Outdoor)

Ground wiring

Strong elec-signal link wiring

Weak elec-signal link wiring

Ground wiring

Indoor

Unit

Outdoor

Unit

• Ground the air conditioner properly in case to affect its anti-interference function

Chart 19

Y&G

XT2

Y&G

XT1

XT1

XT2

T3

E

1N

3

4

L N 1 2(N)

WHITE (T3)

BLACK (E)

12000 Btu/h (1 PHASE)

Air Conditioner Link-circuit

(For R-410A, Cooling & Heating)

18000 Btu/h (1 PHASE)

Air Conditioner Link-circuit

(For R-410A, R-407C and R-22,

Cooling & Heating)

Chart 20

3-core cable 3x2.5mm

2

1-core sheild wire 1x0.5mm

2

5-core cable 5x2.0mm

2

OUTDOOR UNIT

INDOOR UNIT

POWER:

220-240V~50Hz

Chart 18

■

The Specifi cation of Power

Y&G

3

1

2

L

N

3

1 2

L N

XT1

XT2

T3

E

Y&G

XT2

XT1

T3

E

24000Btu/h (1 PHASE)

Air Conditioner Link-circuit

(For R-410A, Cooling & Heating)

24000-36000Btu/h (1 PHASE)

Air Conditioner Link-circuit

(For R-407C, Cooling & Heating)

Chart 21

3-core cable 3x2.5mm

2

1-core sheild wire 1x0.5mm

2

3-core cable 3x2.5mm

2

OUTDOOR UNIT

INDOOR UNIT

POWER:

220-240V~50Hz

3-core cable 3x2.0mm

2

J354-EN.indd 2

J354-EN.indd 2

4/25/07 5:03:07 PM

4/25/07 5:03:07 PM