Redball Electrical 565 User Manual

Page 51

3-07

565 Trailer Sprayer - Maintenance, Service &

Troubleshooting

Section E

6

Section E

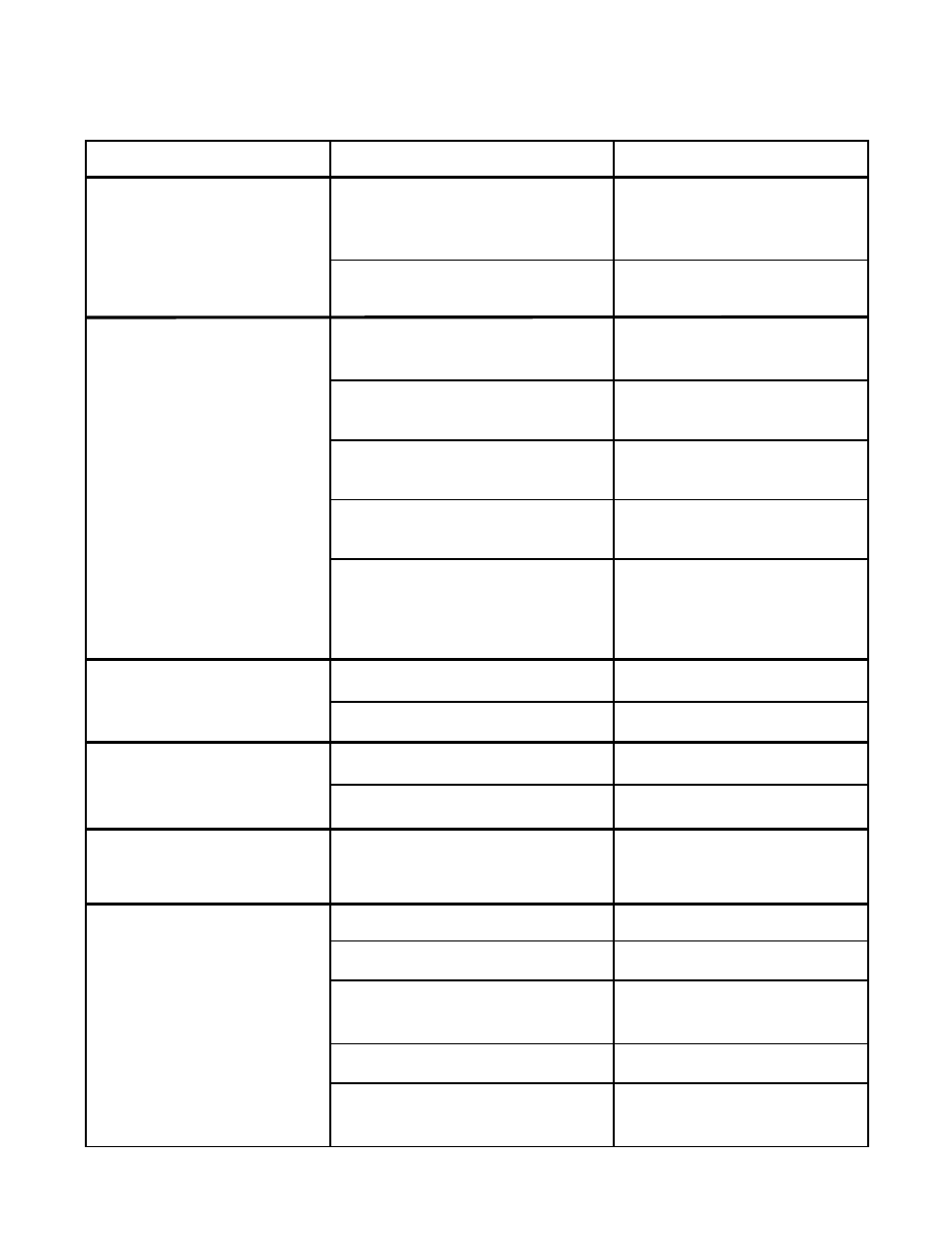

SYMPTOM

PROBABLE CAUSE

CORRECTIVE ACTION

Loss of hydraulic fluid

Fittings and tubes leaking

Tighten loose fittings and

due to leakage

replace worn hoses or

cracked tubing.

Leakage between flange

Repair or replace

and housing

Hydraulic liquid pump

Pump not primed

Check vent line for proper

installation. Clean if necessary.

Low discharge

Air leaks in suction line

Check and reseal inlet

fittings

Blocked/clogged line or boom

Clean out and replace

strainer

Impeller plugged or loose

Inspect and clear

obstruction or tighten

Bypass adjustment set

Adjust bypass screw on

improperly

side of hydraulic motor

to manufacturer’s

specifications

Poor spray pattern

Nozzles too large

See nozzle supplier

- Nozzles dribble

Strainer / nozzle clogged

Clean strainer

- Spray atomizing

Nozzle too small

See nozzle supplier

& blowing around

Tractor speed too fast

Reduce speed

- Spray streaming

Nozzle partially clogged

Remove and clean nozzles

(No uniform pattern)

and strainer

- Won’t spray

Controller not setup

See Control Manual

Valves not in correct position

See Section B

Poor hydraulics or

Troubleshoot hydraulic

no hydraulic power

system

Liquid supply blocked

Clean strainer

Suction line collapsed

Inspect and replace