Redball Electrical 565 User Manual

Page 46

3-07

565 Trailer Sprayer - Maintenance, Service &

Troubleshooting

Section E

1

Section E

Liquid Tank, Frame, and Plumbing

1. Check tank visually for obvious cuts, cracks,

punctures or leaks that could contribute to tank

failure.

2. Check fittings for broken parts, cracks or wear

marks and potential leaks.

3. Check gaskets of the bulk head fitting located on

the sump for wear or weathering.

4. Inspect valves and pump for solid connections and

correct mounting.

5. Inspect the tank lids for cracks and verify they

tighten securely in place.

6. Remove any debris from inside the tanks as they

may become lodged in the strainer or pass into the

pump.

7. Clean strainer daily, more frequently if your liquid

supply is not "free of debris".

8. Inspect all welds and structural components for

tears, bends, cracks or damage. This unit operates

in a corrosive environment. Make certain corrosion

is quickly removed and painted. If corrosion is

deep, replace component or add adequate plating

with welding operation.

Proper maintenance of the Sprayer and the tractor is critical for peak performance,

reliability and accuracy of this system. The following is a guideline of the type of

maintenance and servicing that should be performed on this unit. Your environment and

uses may require additional maintenance and service beyond this list to assure a reliable

and safe unit. The operator of this unit has ultimate responsibility to identify areas of

concern and rectify them before they become a hazard or safety issue. There is no substi-

tute for a trained, alert operator.

IMPORTANT

If any of the above inspections, or others identified, are discovered

REPAIR IMMEDIATELY.

Do not put this unit into operation with any questionably main-

tained parts. Poor performance or a hazard may occur.

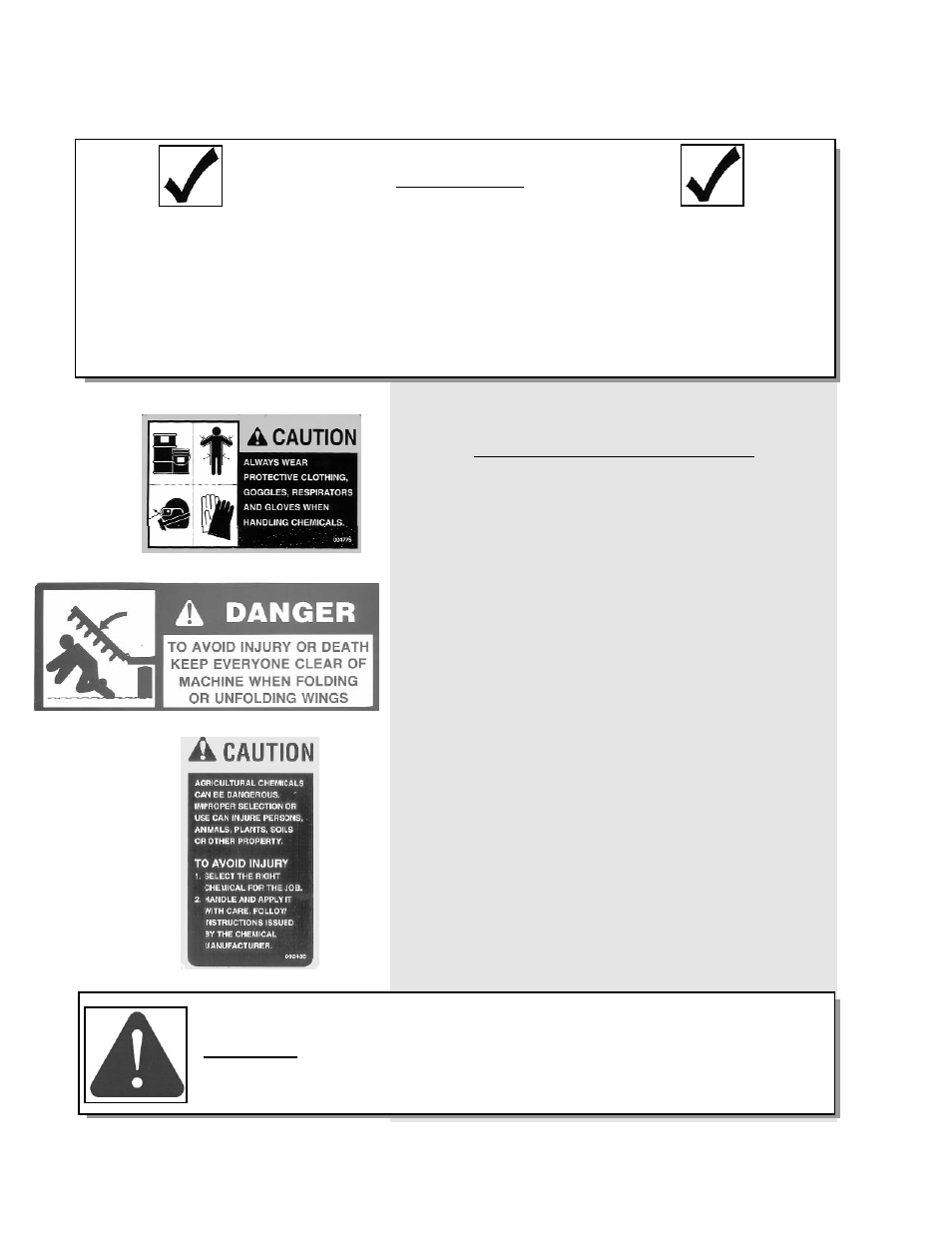

DANGER